Trash can capable of packing automatically

A garbage can and automatic technology, applied in the field of garbage cans, can solve the problems of troublesome garbage bag replacement, easy contact with dirt, inconvenient cleaning, etc., and achieve the effect of outstanding packaging effect, simple packaging mechanism and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

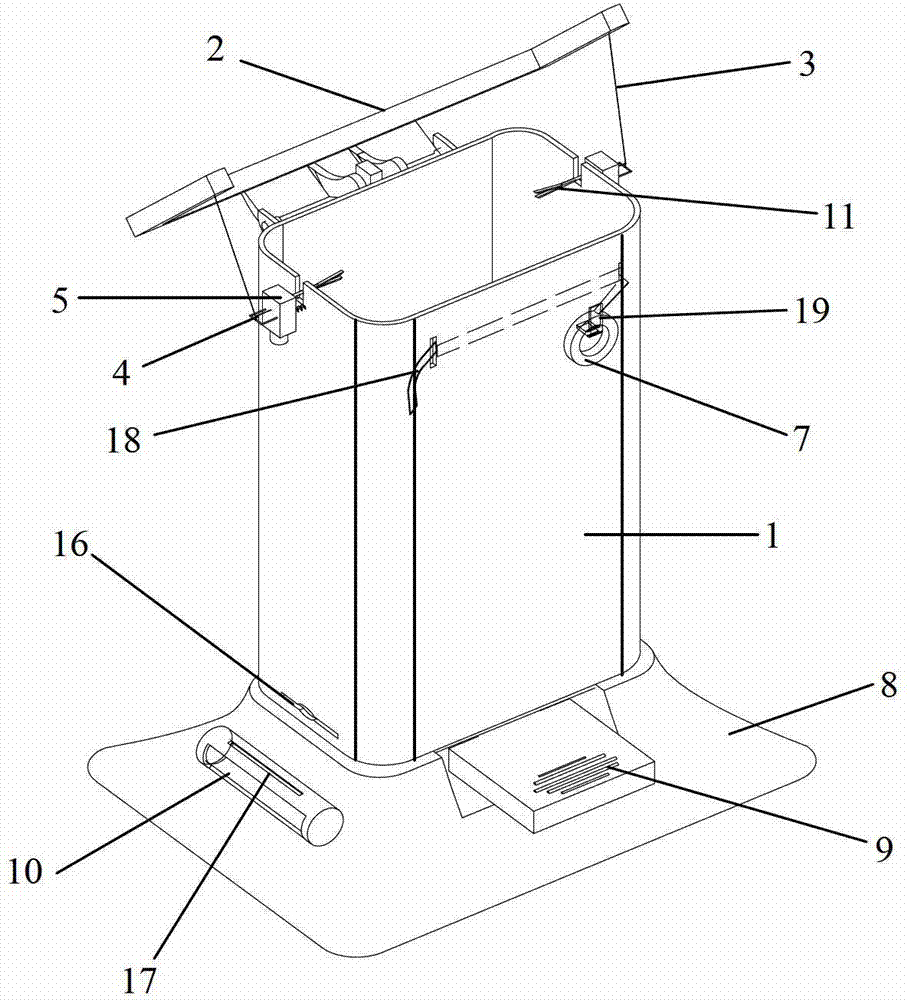

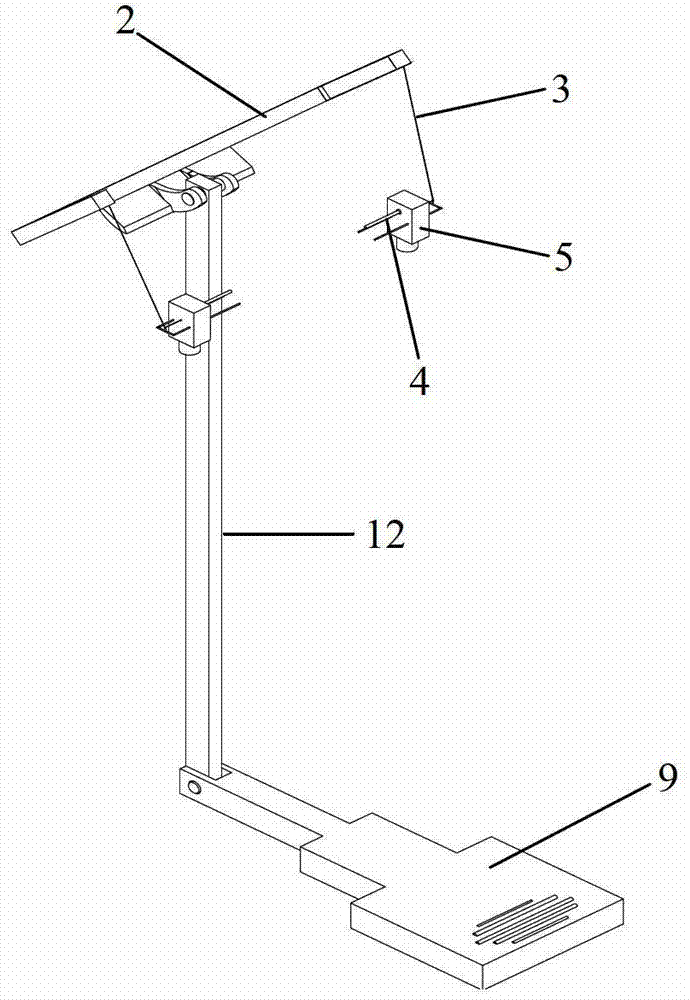

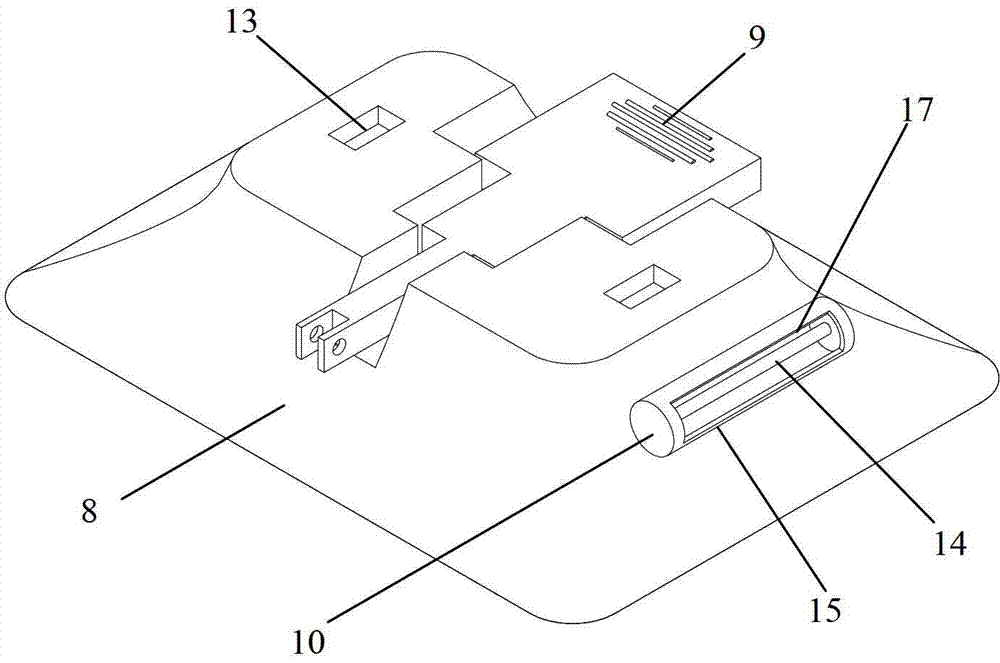

[0023] see Figure 1~4 , the embodiment of the present invention is provided with bucket body 1, lever 2, drawstring 3, motor rail 4, motor 5, spring 6, double-sided adhesive tape 7 at break point, base 8, pedal 9, garbage bag storage room 10, alligator clip 11 , connecting rod 12, battery 13 and pole 19; The lever 2 is located on the mouth of the barrel 1 top, the two ends of the stay rope 3 are connected with the lever 2 and the motor 5 respectively, and the motor guide rail 4 is located on both sides of the barrel 1 On the upper side, the motor 5 is placed on the motor guide rail 4, the two ends of the spring 6 are respectively connected with the barrel body 1 and the motor 5, the pole 19 is fixed on the upper front end of the barrel body 1, and the double-sided adhesive tape 7 at the break point is stored on the pole 19 and fixed on the inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com