Stack generating method for transfer robot

A handling robot and stacking type technology, which is applied in the field of offline stacking type generation of handling robots, can solve problems such as limiting robot functions, avoid mutual interference, reduce the number of judgments, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

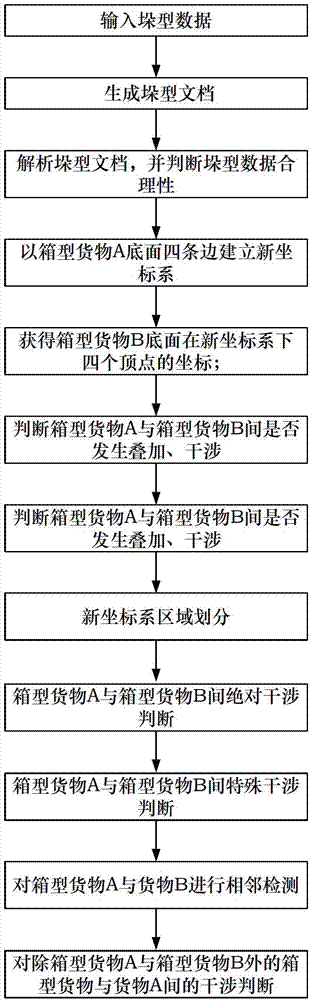

[0046] The present invention is a method for generating stacks for handling robots, such as figure 1 shown, through the following steps:

[0047] Step 1: Generate stacking documents;

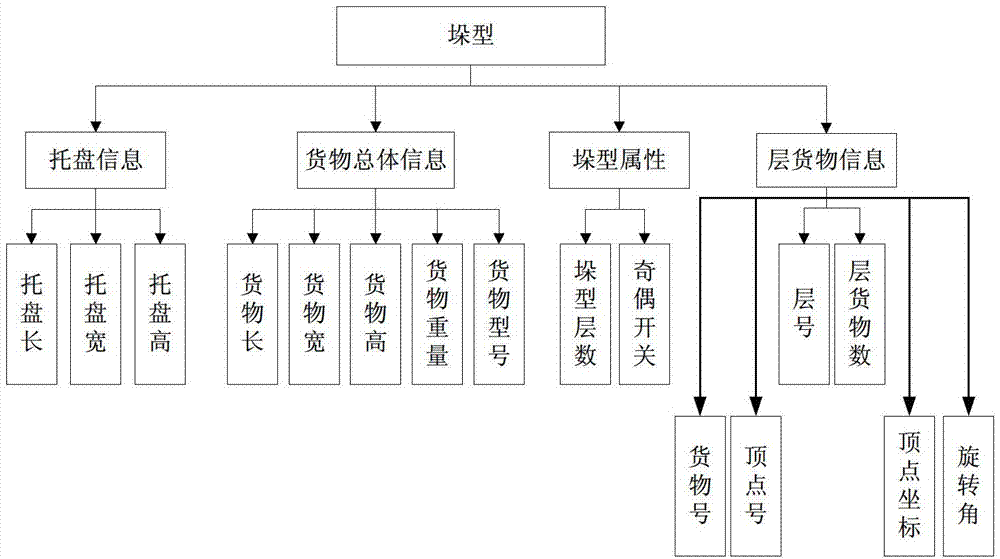

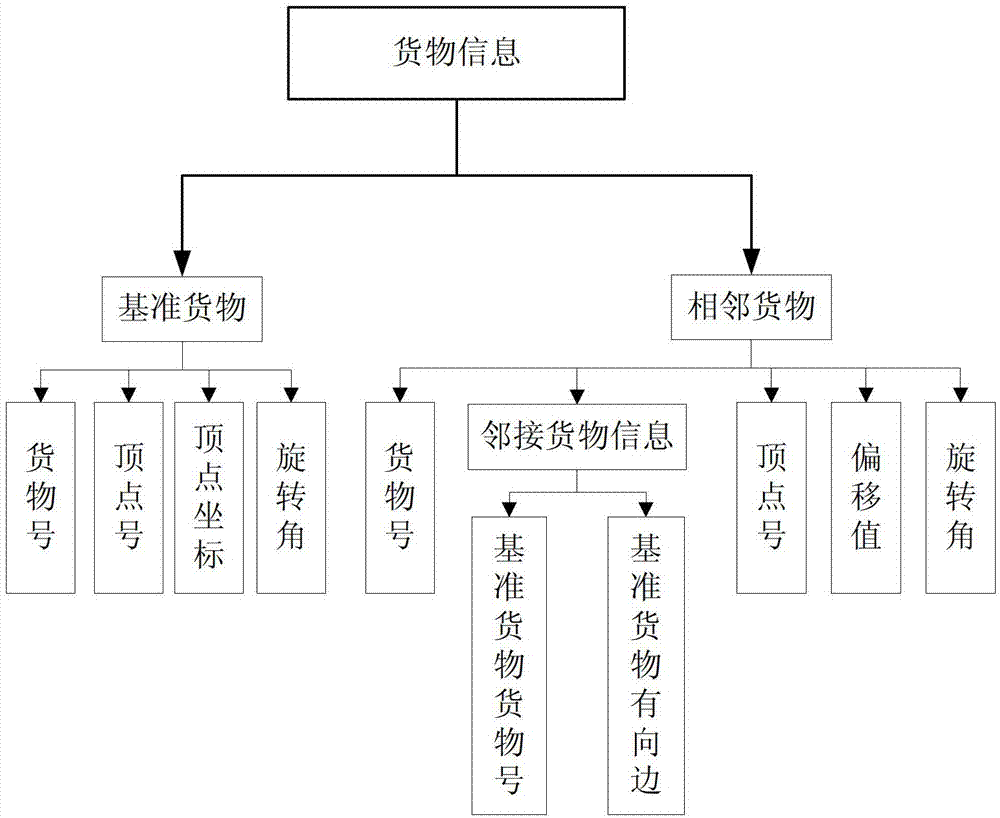

[0048] User-defined stack type data, including pallet information (the length, width, and height of the pallet), overall cargo information (the length, width, height, weight and model of the cargo), stack type attributes (stack type layers, parity switch) and layer cargo Information (layer number, layer number of goods); such as figure 2As shown, among them, the input of layer goods information includes two ways: the first way is to input the goods number of each goods, the number of each vertex on the bottom surface, the rotation angle under the pallet coordinates and the coordinate of one of the vertices on the bottom surface respectively, thus Through the input rotation angle of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com