Water tray type slag removing apparatus for gasification furnace

A gasifier and slag cleaning technology, which is applied in the field of gasifier water pan type slag cleaning devices, can solve the problems of inconvenient slag cleaning and large environmental pollution, and achieves fast cleaning speed, no environmental pollution, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

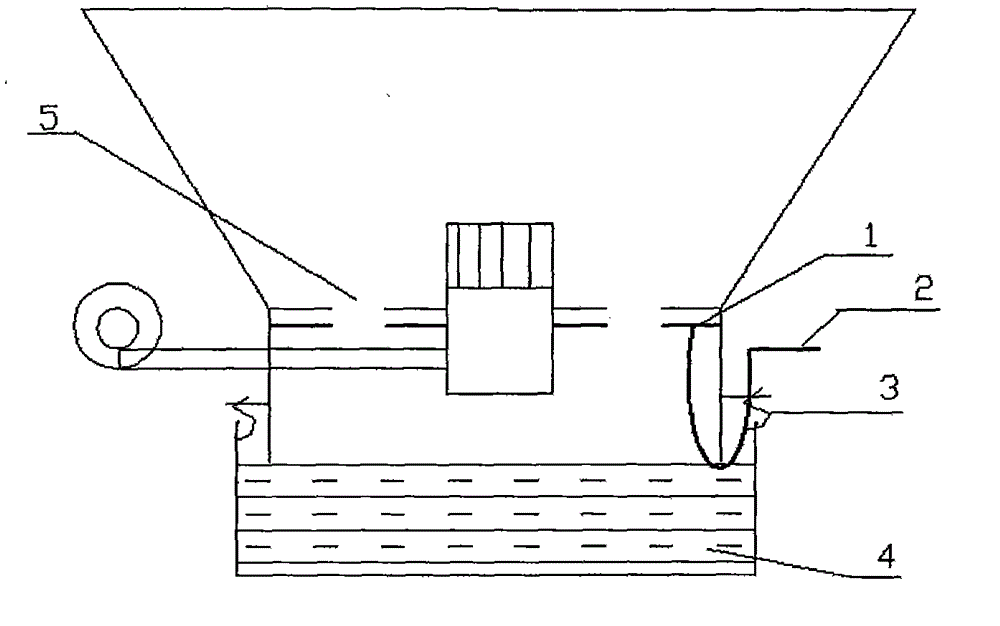

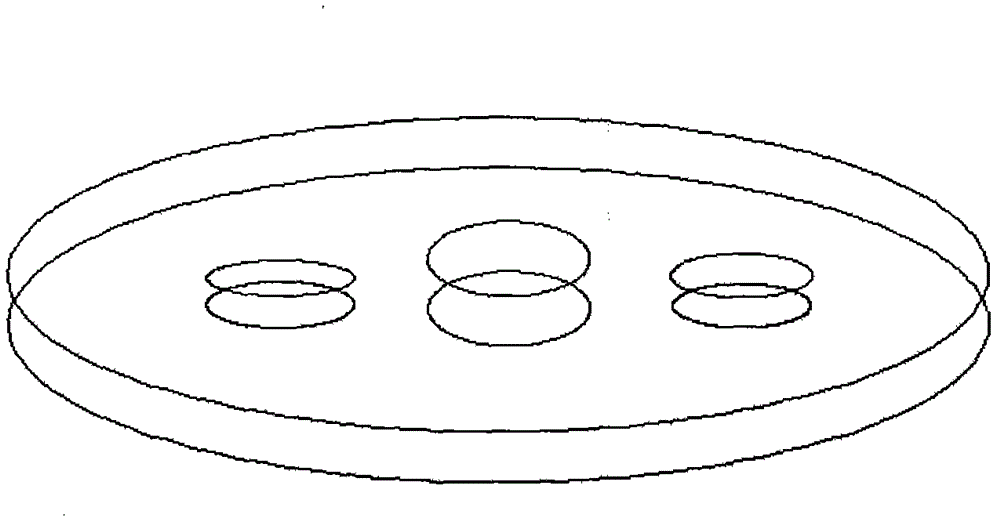

[0012] refer to figure 1 , figure 2 , the gasifier water tray type slag removal device according to the present invention comprises a rotatable slag removal movable plate 1 arranged at the slag removal port 5 at the lower part of the furnace body, and a slag removal switch fixed with the slag removal movable plate 1 and driven to move 2, and the water tray 4 suspended at the bottom of the furnace; the rotatable slag removal movable plate 1 is docked with the slag removal port 5 when the slag removal switch 2 is turned on, and the ash and slag will fall into the water tray 4. The water pan 4 used for slag connection is hung on the body of furnace using a hook 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com