Single Layer Box Section Surface Reticulated Shell Node

A box-shaped and cross-section technology, which is applied in the direction of construction and building construction, can solve the problems of increased project cost and achieve the effects of weld quality, good ductility, and reduced weld density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

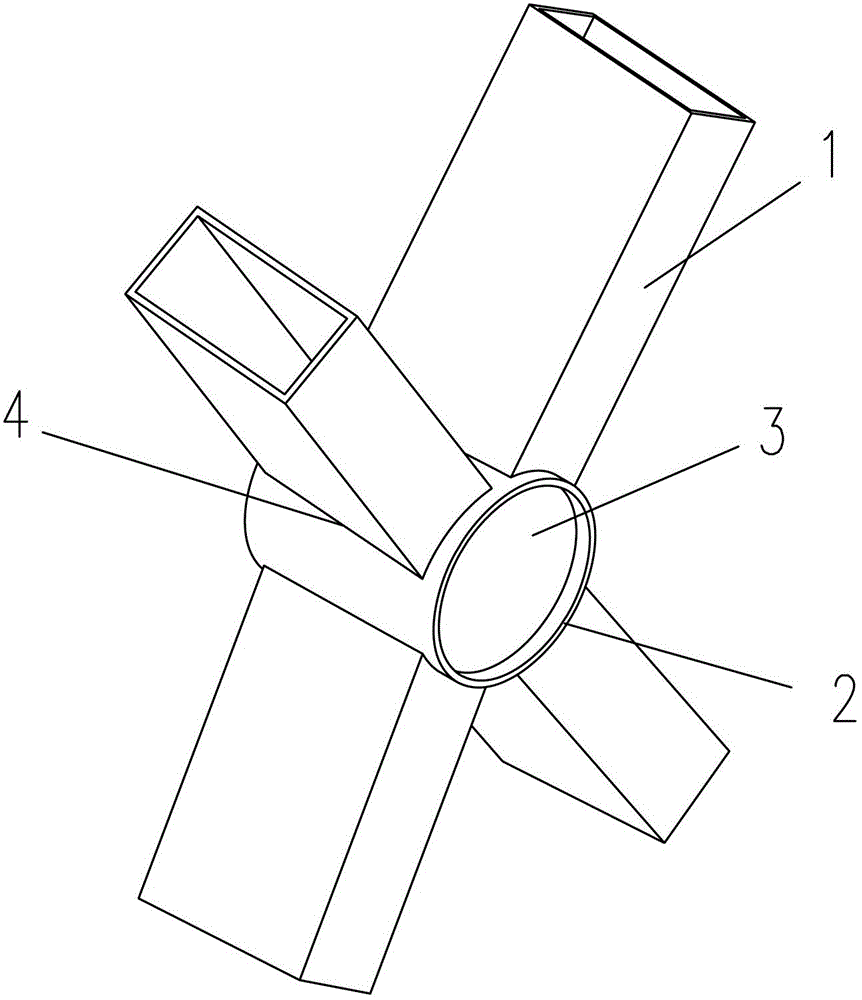

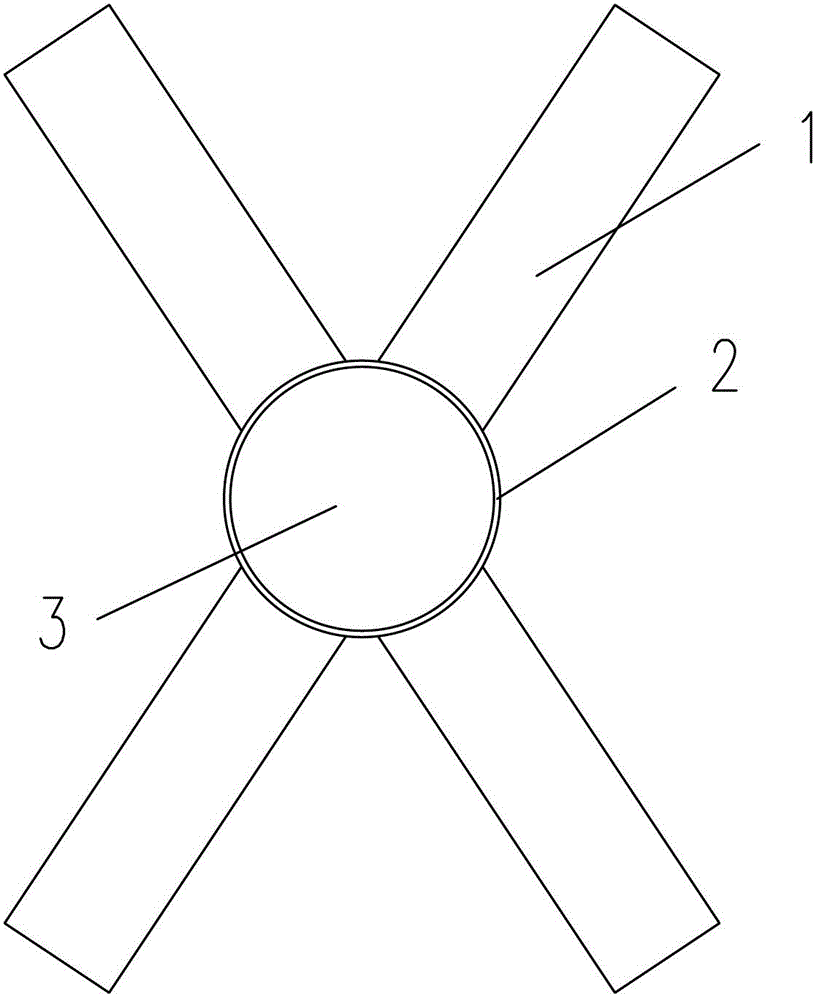

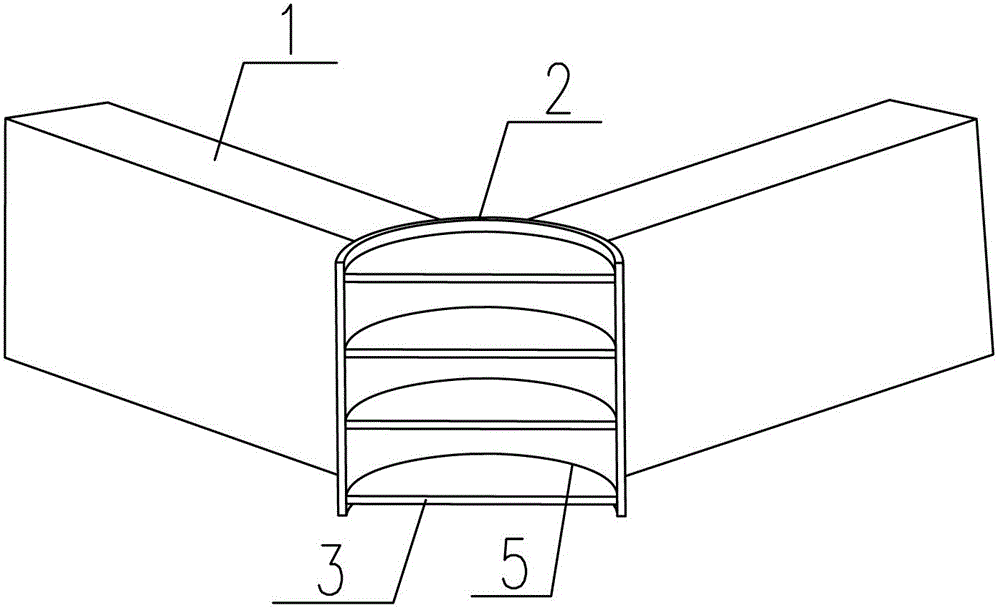

[0021] The single-layer box-section curved reticulated shell node includes a circular tube 2 at the center of the node, a stiffener 3 inside the circular tube, and several box-section rods 1 .

[0022] In this embodiment, there are four box-shaped cross-section rods 1, and the ends of the intersecting lines are cut out by a machine, and connected to the round pipe 2 at the center of the node through a full-penetration butt weld 4 . The stiffening plate 3 matches the inner diameter of the round pipe 2 at the center of the joint, and is connected to the round pipe 2 at the center of the joint through the fillet weld 5 of the stiffening plate. The curved surface where the axis of each box-shaped section member 1 is located may be a plane, a spherical surface, an elliptical surface, a cylindrical surface or a hyperboloid.

[0023] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com