Digital and intelligent lifting control device

A technology of a control device and a lifting device, which is applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve problems such as not true synchronization, difficult to achieve synchronization and stable lifting, and inconsistent response time of lifting motors. , to achieve the effect of ensuring synchronization and safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

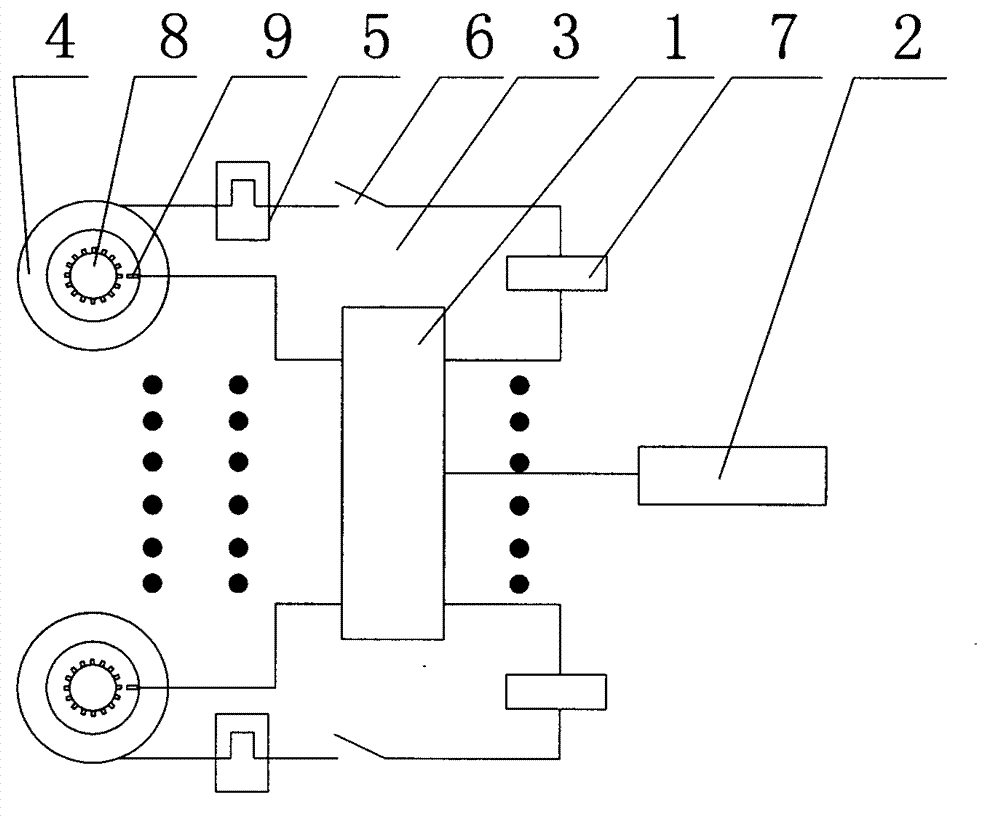

[0010] Such as figure 1 As shown, a digital intelligent lifting control device includes a PLC controller 1 and a control panel 2 electrically connected to the PLC controller 1. There are multiple groups of lifting devices 3 connected to the PLC controller 1, and each group of lifting devices 3 includes The lifting motor 4, the thermal relay 5, the contactor 6 and the drive circuit 7 connected to the lifting motor 4 in turn, the driving circuit 7 is connected with the PLC controller 1, and each lifting motor 4 is provided with a The connected speed sensor 9 is used to receive the transmission signal of the speed measuring gear 8 in the lifting motor 4 .

[0011] The present invention operates like this: through the setting value of the control panel 2, the control panel 2 sends a lifting command to the PLC controller 1, and after the calculation of the PLC controller 1, the driving circuit 7 is controlled, and the lifting motor is driven through the contactor 6 and the thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com