Optical lever measurement method for magnetostrictive effect based on magnetorhrologic grease and measuring device for optical lever measurement method

A magneto-rheological grease and magnetostrictive technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as reduced measurement accuracy, difficulty in angle adjustment, and inability to measure nanoscale displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

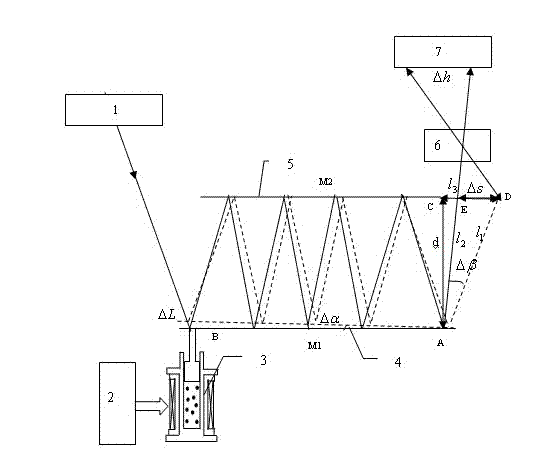

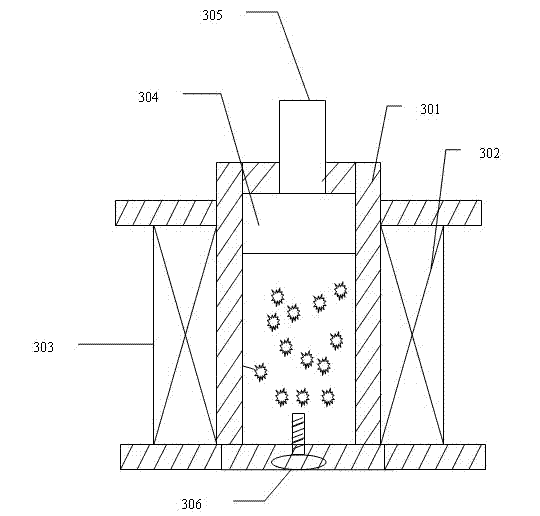

[0080] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the invention will be described in detail below through examples in conjunction with the above-mentioned figures. see figure 1 As shown, it is a block diagram of an optical lever measurement system. The present invention is an optical lever method measuring device for measuring magneto-rheological grease magnetostriction, including a laser emission system 1, a DC power supply 2, and a magneto-rheological grease magnetostrictive micro-displacement driver 3. The plane mirrors 4 and 5 in the microsystem, the displacement optical imaging amplification system 6, and the signal processing system 7.

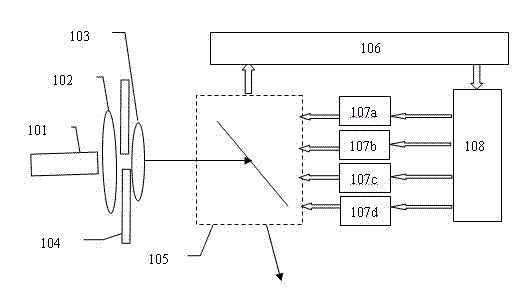

[0081] The 1 laser emission system. see figure 2 As shown, it is a laser emitting system 1 . An angle sensor 106 is fixed on the He-Ne laser 101 , and the laser light emitted by the laser passes through the collimating mirror 102 , the aperture stop 104 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com