Energy Absorbing Resistors for Braking Systems of Electric Locomotives

A brake system and energy absorption technology, applied in the direction of electric brake system, resistors, resistor parts, etc., to achieve the effect of improving safety and reliability, small size, and reducing the risk of easy burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

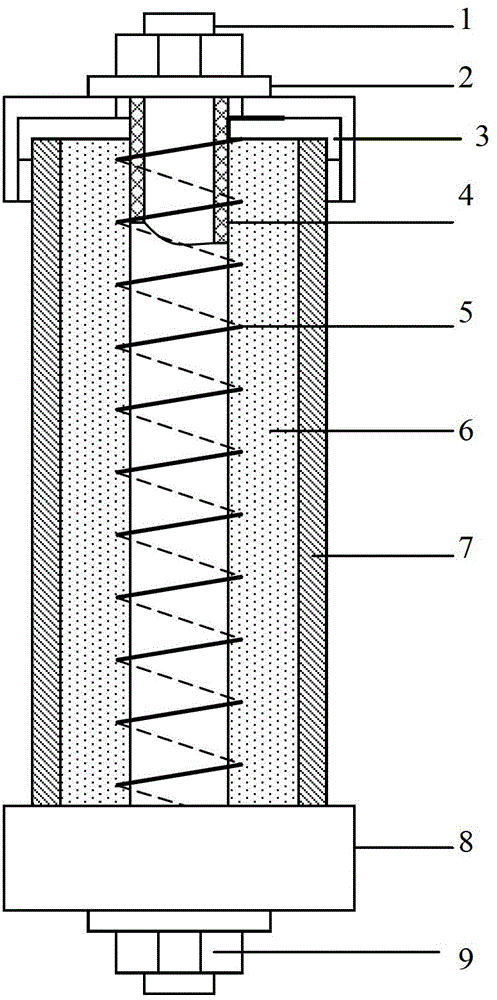

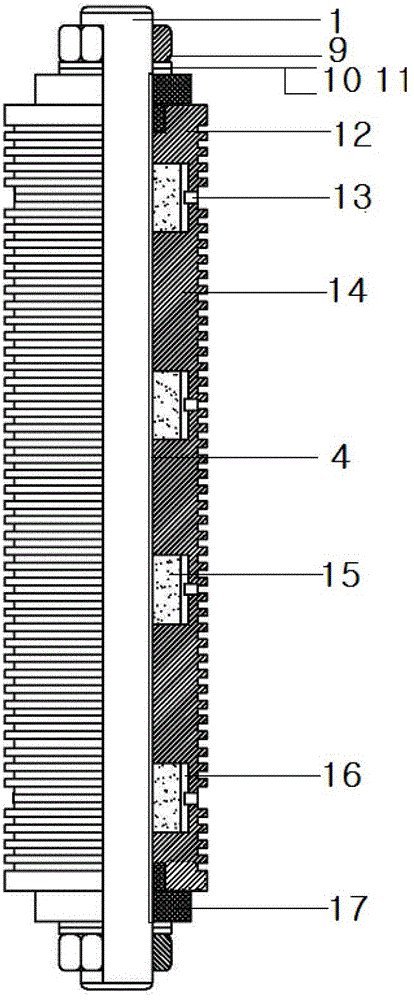

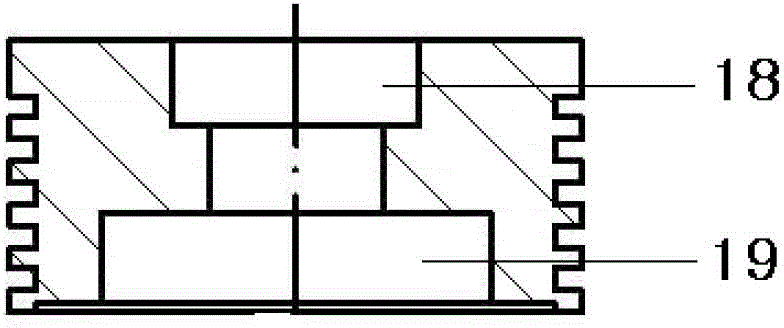

[0021] see figure 2 , an energy absorbing resistor used in the braking system of an electric locomotive, comprising an insulating sleeve 4 and a metal rod 1 therein, four ceramic resistance sheets 15 are worn on the outer circumference of the insulating sleeve, and two ceramic resistance pieces 15 are worn on the outer circumference of the insulating sleeve The end heat sink 12 and three intermediate heat sinks 14, wherein the end heat sinks are located at both ends of the insulating sleeve, and the middle heat sink is located at the middle outer circumference of the insulating sleeve between the two ends of the heat sink. Between the middle heat sinks, between the end heat sinks and the middle heat sinks are electrically connected through ceramic resistors 15, and the ceramic resistors are zinc oxide ceramic linear resistors. Both ends of the metal rod are provided with threads, and the two end radiators 12 and the three intermediate radiators 14 (including four zinc oxide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com