Ultrasonic wire deicing device and method thereof

An ultrasonic and electric wire technology, which is applied in the field of electric wire ultrasonic deicing devices, can solve problems such as economic property loss and power grid hazards, and achieve the effects of long service life, low production cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

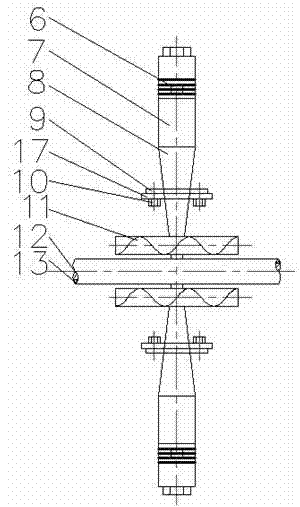

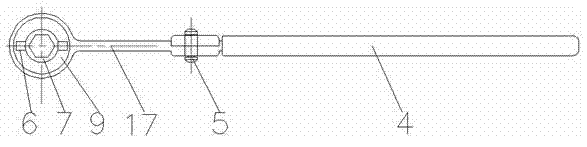

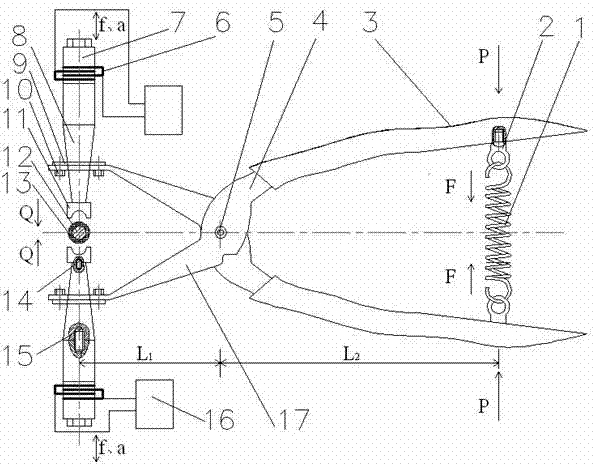

[0020] Such as figure 1 As shown, the wire ultrasonic deicing device includes a tension spring 1, a hanging ring 2, an insulating sleeve 3, a deicing pliers handle 4, a rivet 5, a screw 10, an ultrasonic generator 16 driven by a DC power supply, a deicing pliers head 17 and an ultrasonic acoustic System; the deicing pliers handle 4 is connected with the deicing pliers head 17 to form a pliers body. The left end of 17 is respectively provided with an ultrasonic acoustic system, and the ultrasonic acoustic system includes an electrode 6, a sandwich piezoelectric transducer 7, a horn 8, a flange 9, a tool head 11, a first bolt 14 and a second bolt 15, and a sandwich The piezoelectric transducer 7 is connected with the horn 8 through the second bolt 15, the horn 8 is connected with the tool head 11 through the first bolt 14, and the piezoelectric transducer 7 is driven by the electrode 6 with the DC power supply. The ultrasonic generators 16 are connected, and the two horns 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com