Method and apparatus for cooling and/or deep-freezing materials implementing the injection of two cryogenic liquids

A low-temperature liquid, cooling method technology, applied in household refrigeration devices, preservation of meat/fish by freezing/cooling, applications, etc., can solve the problems of difficult distribution of cold spots, small output, limitations, etc., to avoid the effect of over-speed discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

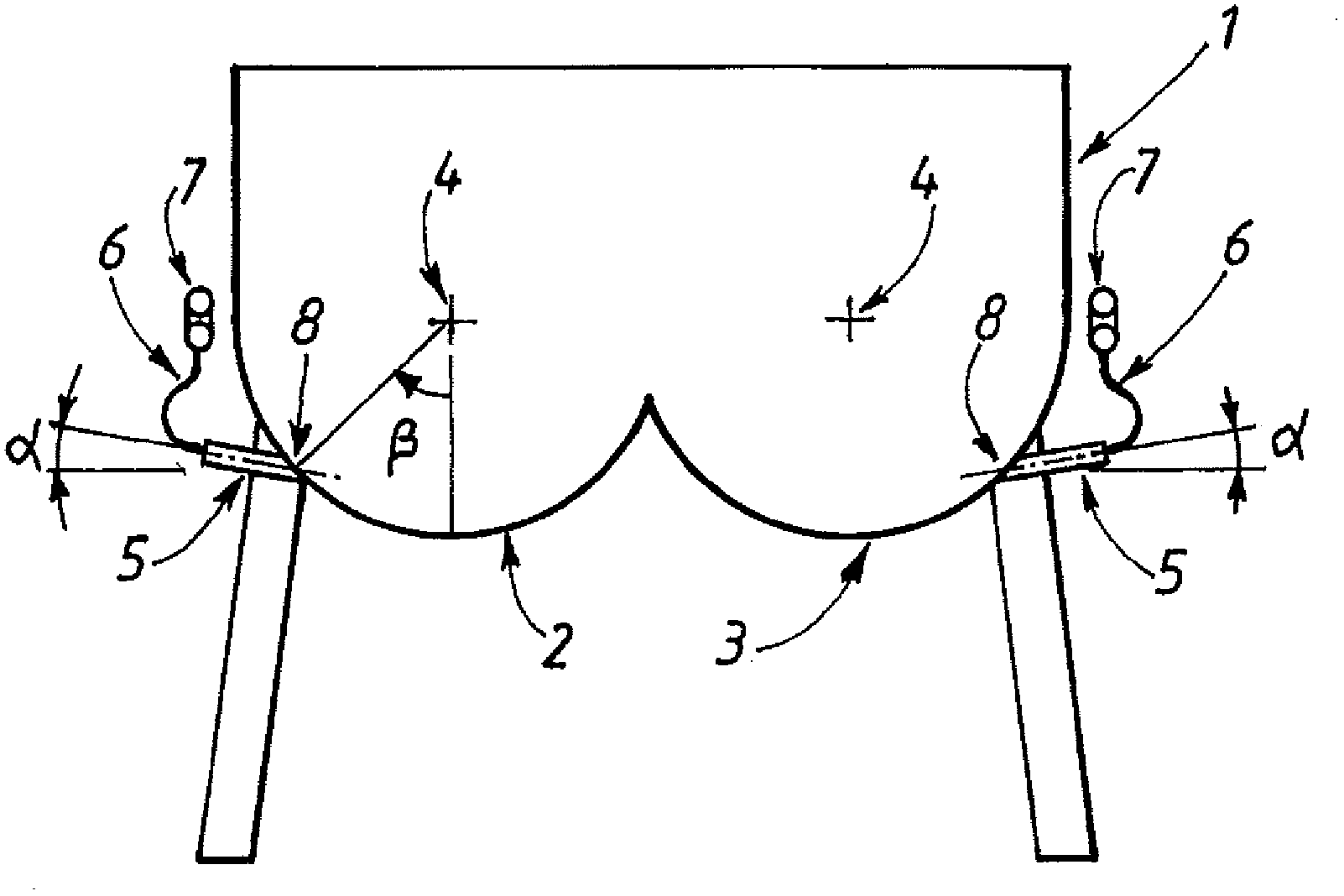

[0068] figure 1 The lower part of a conventional prior art mixer (for example a meat mixer) is shown, which has two tanks 2 and 3, where a series of cryogenic fluids such as liquid nitrogen nozzles are used on each side of the device.

[0069] The figure symbolically shows the cryogenic liquid nozzle connected to the wall of the mixer by the reference number 5. The nozzle itself is advantageously as the figure 1 The conveying and supply rail 7 located above the nozzle as shown in the figure is supplied via a hose 6.

[0070] In order not to mess up the figure unnecessarily, the axis of the rotor shaft of the mixer is represented by a simple cross with the number 4, such as figure 1 Each groove of the mixer shown has an axis.

[0071] If you are examining the figure 1 It can be understood that the position of the nozzle along the wall of each groove (angle β) and the inclination angle of each nozzle with respect to the horizontal direction (angle α) in this case have favorable valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com