Fruit picking rolling shaft anti-winding device for peanut combine harvester

A combine harvester, anti-winding technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of weeds and residual plastic film winding, etc., to solve the effect of winding fruit picking rollers, simple structure and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

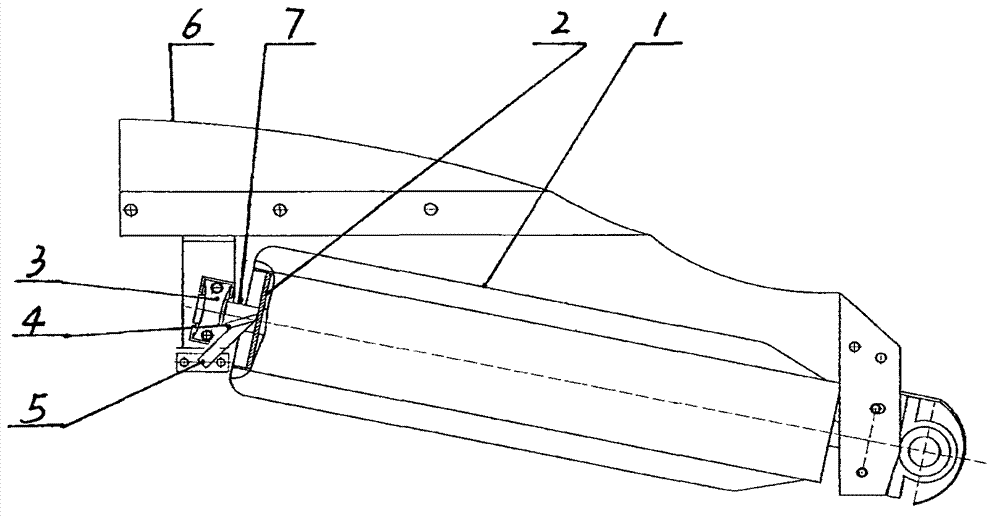

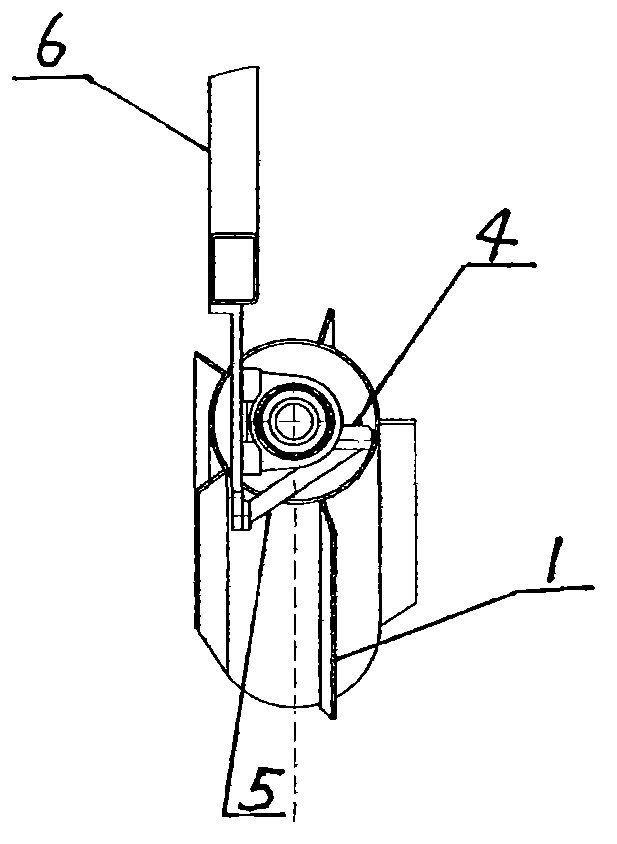

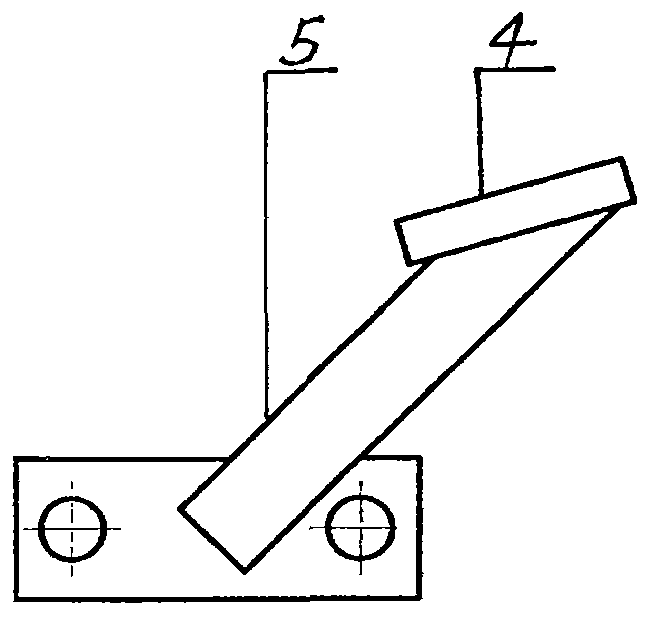

[0013] in figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In, the fruit picking roll anti-winding device is installed between the upper end flange end 2 of the fruit picking roller 1 and the bearing seat 3. The fruit picking roll anti-winding device is mainly composed of a scraper 4 and a scraper bracket 5. 5Fixed installed on the frame 6, the scraper 4 is a square flat plate, fixed on the scraper bracket 5 by welding, the scraper 4 is installed obliquely with respect to the end face 2 of the upper end flange of the fruit picking roller 1, in an inclined direction Contrary to the direction of rotation of the fruit picking roller 1, the edge of the sloped surface of the scraper 4 close to the flange end surface 2 is close to the upper end flange end surface 2 of the fruit picking roller 1, but does not touch. The working principle and process are: the weeds and residual mulching film produced by the fruit picking roller 1 rotating during the work process are transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com