Cylindrical shell type fruit picking roller anti-winding device of peanut combine harvester

A combine harvester and anti-winding technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of shaft winding, difficult cleaning, easy access to weeds and residual film, etc., and achieve low production cost , Reliable use, solve the effect of winding the fruit picking roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

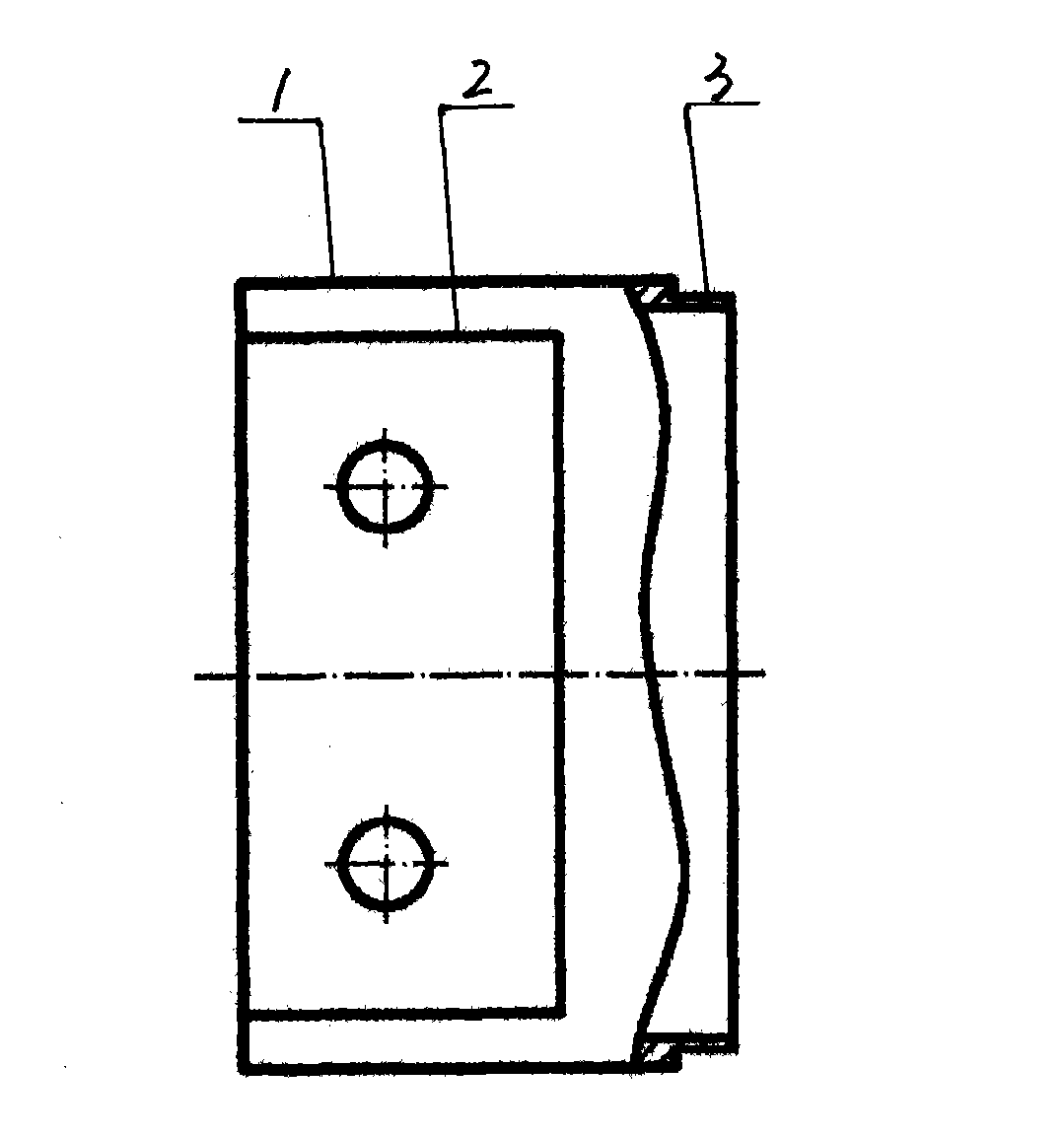

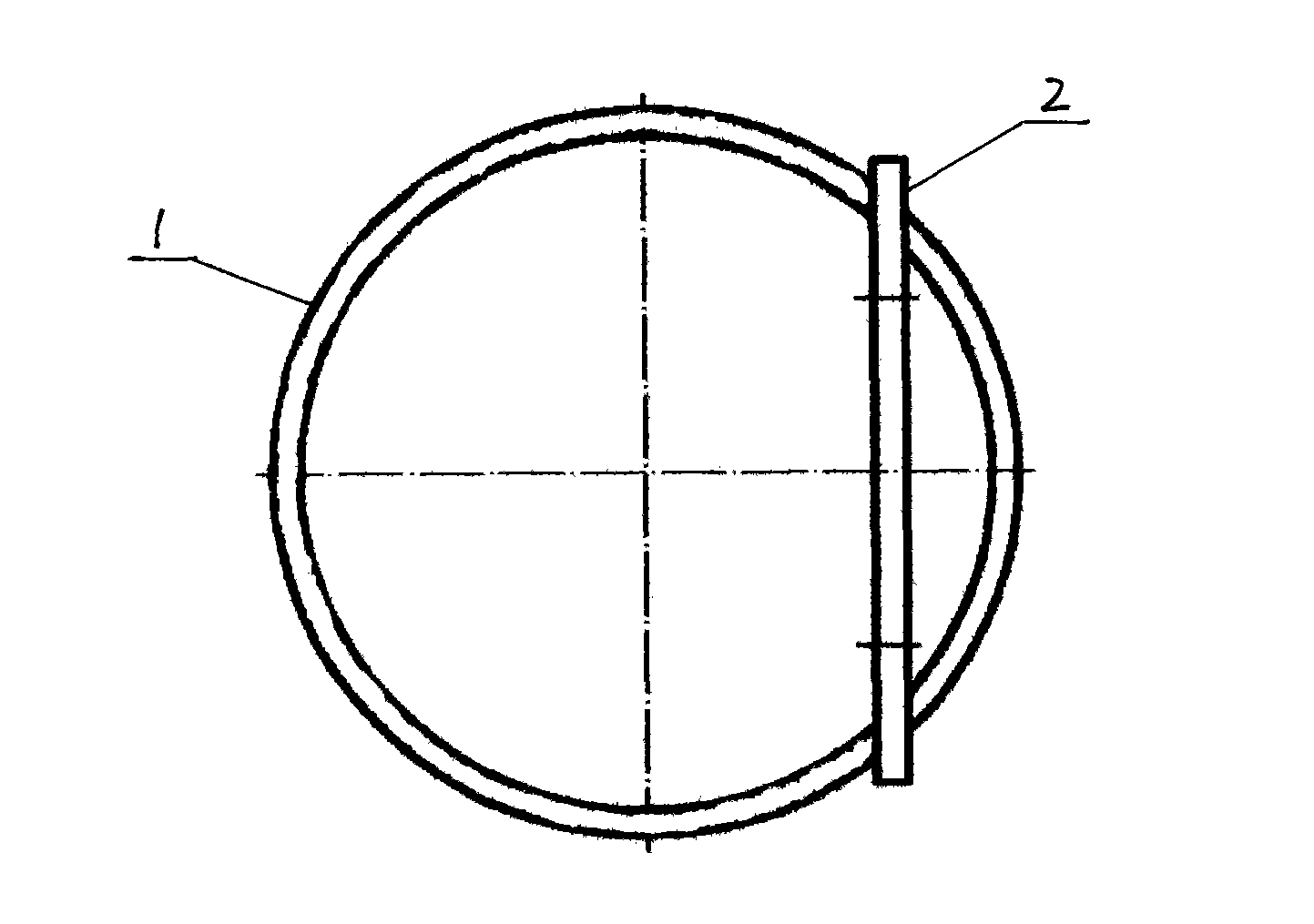

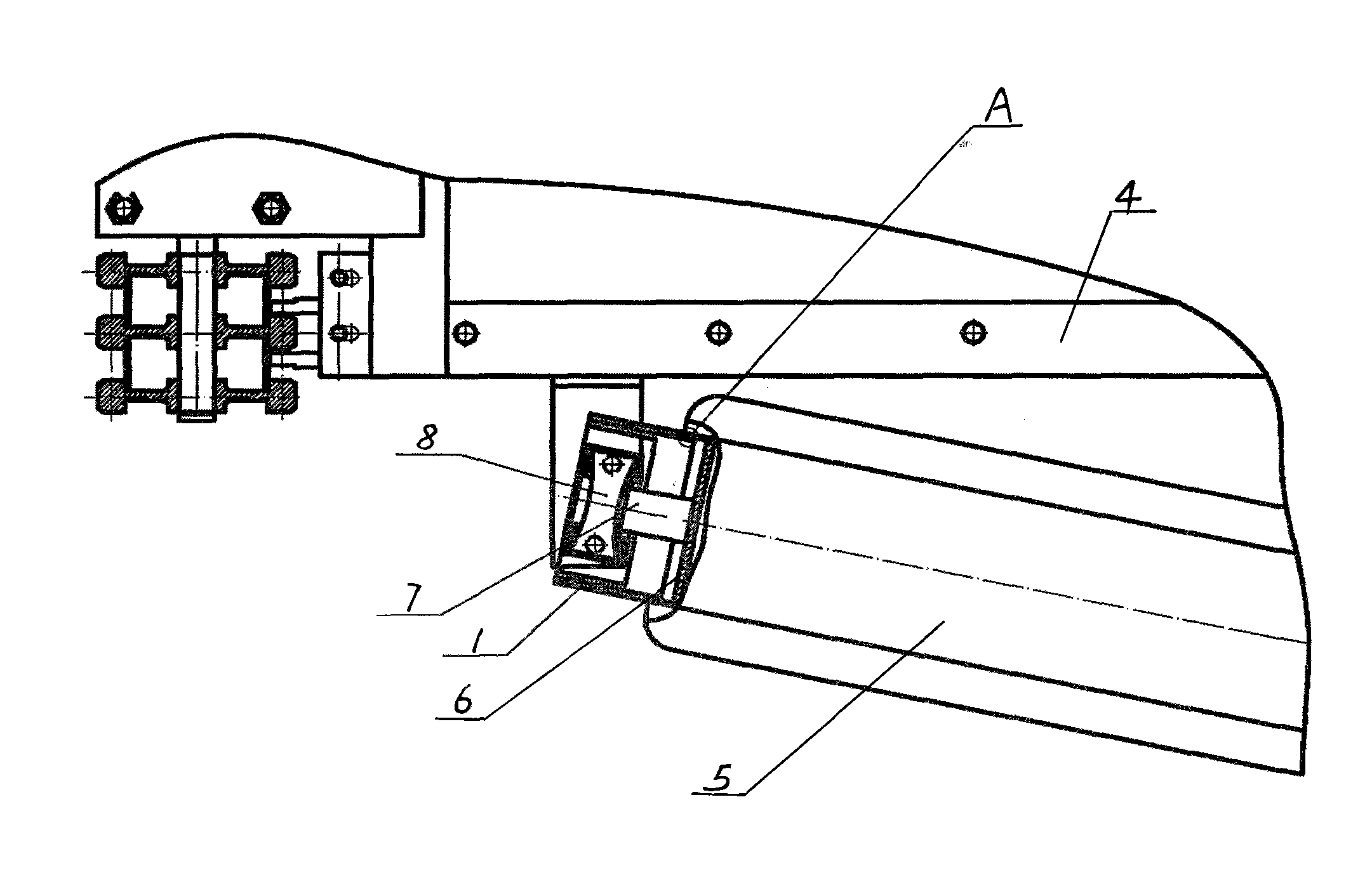

[0014] Install the cylindrical shell-type fruit-picking roller anti-winding device at the position between the upper end flange plate end face 6 of the fruit-picking roller 5 and the fruit-picking roller bearing seat 8, and the cylindrical shell-type fruit-picking roller anti-winding device is mainly composed of The cylindrical shell 1 is composed of a cylindrical shell fixing plate 2 fixed on one side of the cylindrical shell 1. One end of the cylindrical shell 1 is provided with a ring belt 3 whose diameter is smaller than the outer diameter of the cylindrical shell 1. The outer diameter of the ring belt 3 is the same as The nominal size of the inner diameter of the upper end cylinder 9 of the fruit picking roller is equal, the outer diameter of the ring belt 3 is a negative tolerance, the inner diameter of the upper end roller 9 of the fruit picking roller is a positive tolerance, the outer diameter of the ring belt 3 is matched with the inner diameter of the upper end roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com