Centrifugal micro-fluidic chip for detecting oil and grease and preparation method of centrifugal micro-fluidic chip

A technology of microfluidic chips and detection chips, which is applied in the direction of chemical instruments and methods, measuring devices, and laboratory containers, can solve problems such as no substantial breakthroughs, achieve good application prospects, simplify pretreatment, The effect of shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

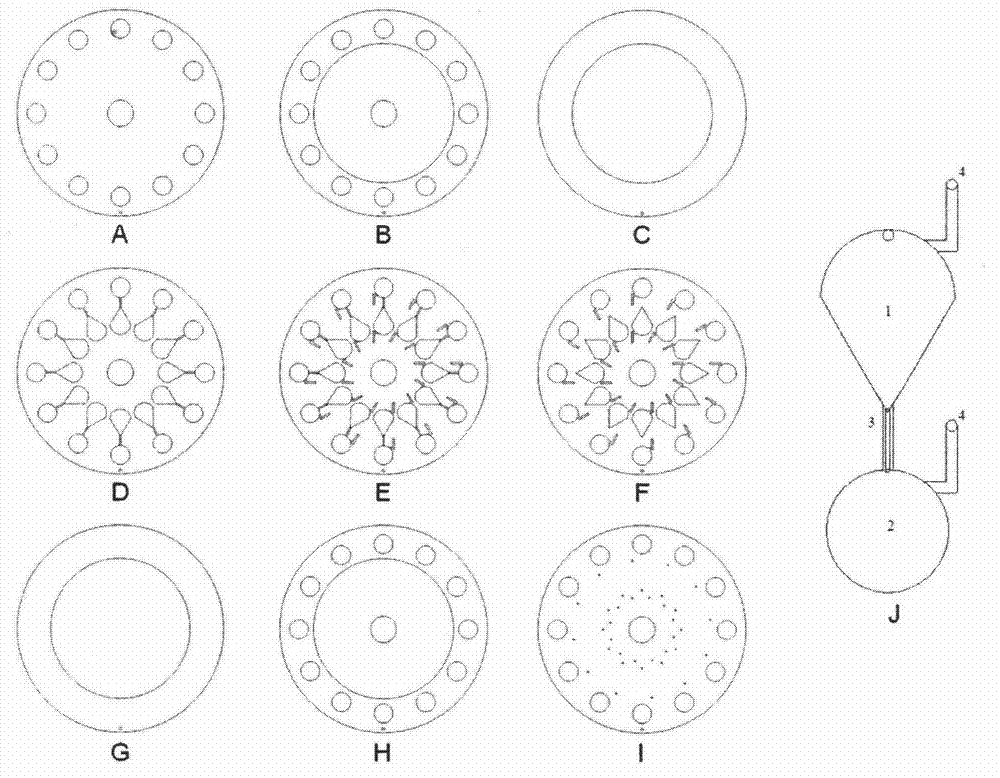

Embodiment 1

[0028] The microstructure and microchannel graphics of the nine-layer chip of the centrifugal microfluidic chip were designed and drawn by computer-aided design software. The microstructures and microchannels were prepared on the three-layer polymethyl methacrylate (PMMA) chip by the CNC micromachining system. The chips of each layer were cleaned with tap water and distilled water respectively, and the remaining fingerprints, oil stains and other stains on the surface of the chip were wiped with ethanol. On the two-layer Teflon film and the four-layer double-sided adhesive film, the required microstructure and microchannel are prepared by cutting plotter. Put 5 mg of soil sample or standard oil sample in the extraction cell, carefully align, bond, and press-seal the nine-layer chip to make a centrifugal microfluidic chip for detecting oil and grease. Fix the centrifugal microfluidic chip on the rotating platform of the centrifuge through a suction cup, and add 100 μL C from th...

Embodiment 2

[0030] The microstructure and microchannel graphics of the nine-layer chip of the centrifugal microfluidic chip were designed and drawn by computer-aided design software. The microstructures and microchannels were prepared on the three-layer polycarbonate (PC) chip by the numerical control CNC micromachining system. Finally, the chips of each layer were cleaned with tap water and distilled water, and the remaining fingerprints, oil stains and other stains on the surface of the chip were wiped with ethanol. On the two-layer Teflon film and the four-layer mechanoadhesive film, the required microstructure and microchannel were prepared by cutting plotter. Put 5mL water sample or standard oil sample in the extraction pool, carefully align, bond, and press-seal the nine-layer chip to make a centrifugal microfluidic chip for detecting oil and grease. Fix the centrifugal microfluidic chip on the rotating platform of the centrifuge through the card slot, and add 100 μL C from the samp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap