Low-frequency ultrasonic atomizing spray nozzle with large atomization amount

An ultrasonic atomization and low-frequency technology, which is applied in spraying devices, liquid spraying devices, botanical equipment and methods, etc., can solve problems such as fatigue fracture, large impact on atomization performance, and narrow particle size spectrum of nutrient solution droplets. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

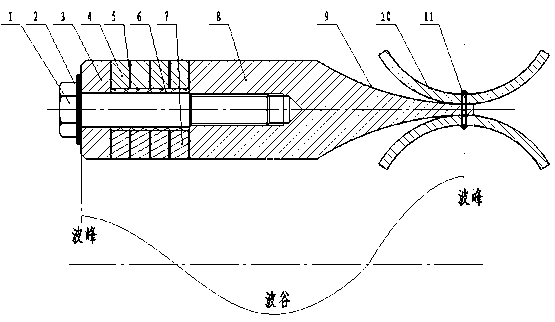

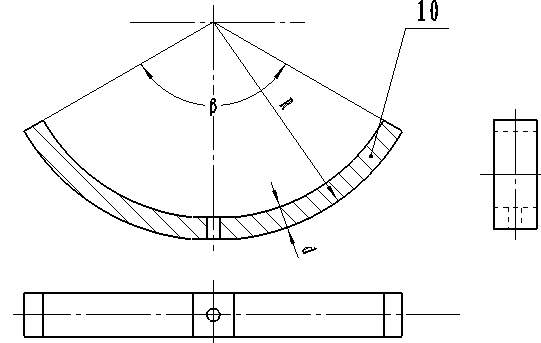

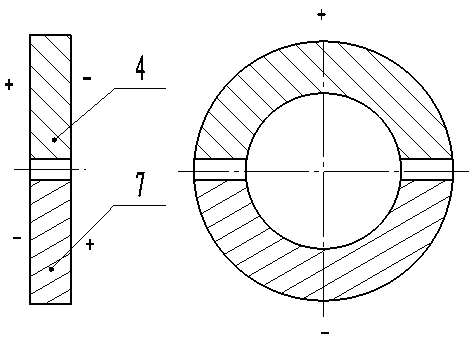

[0022] The present invention is based on the double-end face low-frequency ultrasonic atomizer of bending vibration transducer; figure 1 As shown, it includes fastening screw 1, gasket 2, transducer rear cover plate 3, four positively polarized piezoelectric ceramic semi-circular plates 4, electrodes 5, rubber sleeve 6, four reverse polarized Polarized piezoelectric ceramic semi-circular piece 7, transducer front cover plate 8, horn 9, two symmetrically arranged spherical end faces 10, fastening double-headed symmetrical studs 11; The fastening screw 1 and the insulating sleeve 6 sandwich the piezoelectric ceramic ring piece and the electrode 5 between the front cover plate 8 and the rear cover plate 3 of the transducer. There are two sets of piezoceramic rings, a total of 4; each piezoceramic ring is composed of 1 positively polarized and 1 reversely polarized piezoelectric ceramic half ring, and its polarization Direction such as image 3 The polarization direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com