Static braking device for flat car

A technology of braking device and flatbed vehicle, applied in the directions of brakes, braking components, vehicle components, etc., can solve problems such as affecting the safety performance of vehicles, automatic landslides, automatic sliding of flatbed vehicles, etc. , the effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

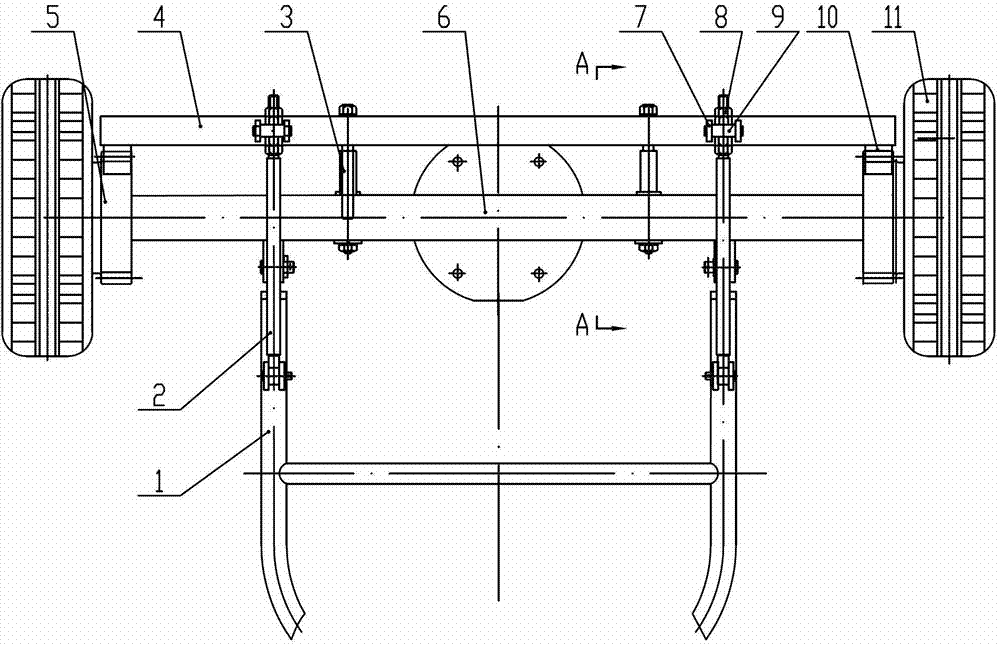

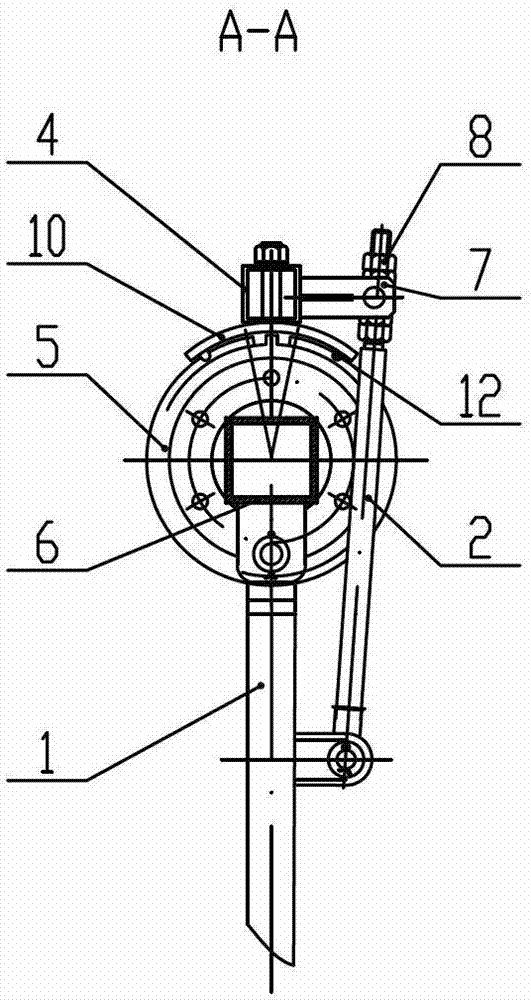

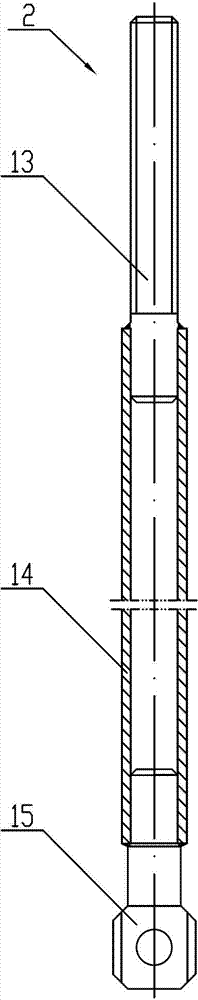

[0020] Figure 1~Figure 9 Among them, it includes traction handle 1, link bolt 2, guide post guide assembly 3, brake beam 4, ratchet 5, wheel axle 6, lug plate 7, nut 8, pin shaft 9, toothed brake pad 10, wheel 11, Brake pad teeth 12, screw rod 13, connecting pipe 14, joint head 15, guide post 16, thread 17, conduit 18, bolt 19, arc plate 20, round hole 21, etc.

[0021] Such as figure 1 , figure 2 As shown, the present invention is a static braking device for a flatbed vehicle, which is generally arranged on the front wheels of the flatbed vehicle, and includes a wheel 11, a wheel shaft 6 and a traction handle 1, and the wheel shaft 6 is installed between two wheels 11, two The inner side of the wheel 11 is respectively fixed with ratchets 5, the traction handle 1 is hinged on the wheel shaft 6 through two hinge points, two link bolts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com