Differential anti-overlap micromotion mechanism of rotor spinning machine

A rotor spinning machine, anti-overlapping technology, applied in the field of spinning machinery and equipment, can solve the problems of reducing the service life of the yarn pressing roller, affecting the yarn quality of the yarn, and unbalanced yarn holding force, etc., to improve The effect of extending the service life, the interval time, and reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment, further explain content of the present invention:

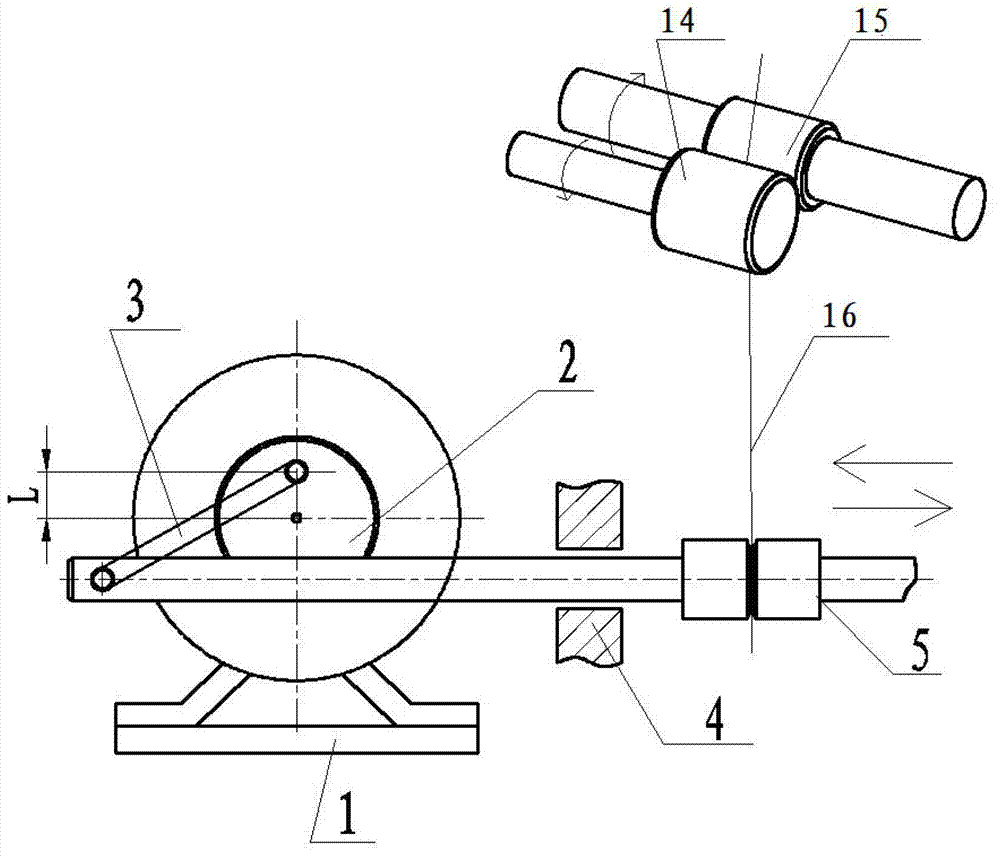

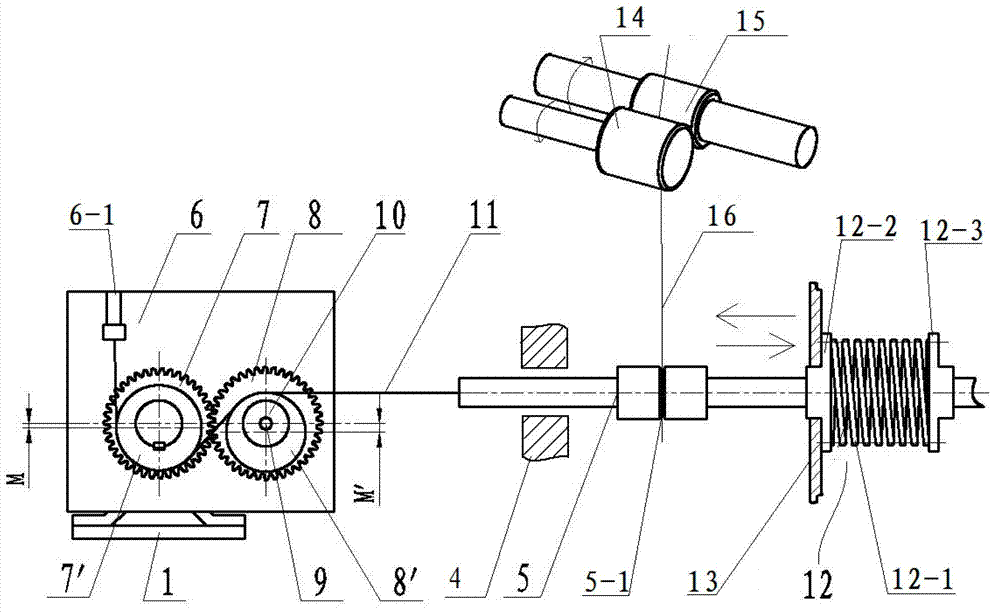

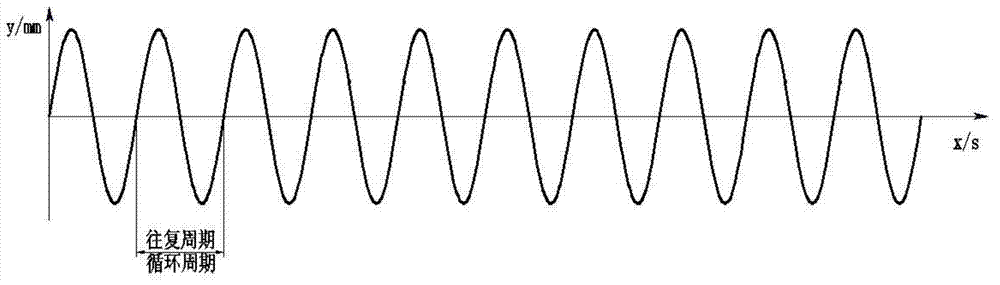

[0029] Such as figure 2 As shown, a differential anti-overlap micro-motion mechanism of a rotor spinning machine includes a micro-motion rod 5 horizontally arranged through a guide hole 4, and above the micro-motion rod is a yarn pressing roller 14 and a yarn delivery roller 15, The yarn 16 is closely attached to the groove 5-1 on the micro-moving rod and is drawn upward by the yarn drawing roller and the yarn pressing roller. The right end of the micro-moving rod passes through the wallboard 13, and an elastic Tensioning device 12, the left side of the micro-movement rod is provided with a micro-motion seat 6, and the speed reducer 1 and two left and right gears arranged side by side and meshing with each other are installed on the micro-motion seat. The other gear is a driven gear, and the driven gear 8 is installed on the micro-movement seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com