Air cylinder and cylinder head matching body

A matching body and cylinder head technology, applied in the direction of cylinder head, cylinder, liquid displacement machinery, etc., can solve the problems of cost increase, easy damage of cylinder gasket, reduction of cylinder head's bearing capacity of cylinder implosion pressure, etc., to increase The gas pressure in the cylinder, the structure is simple, and the effect of eliminating the bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

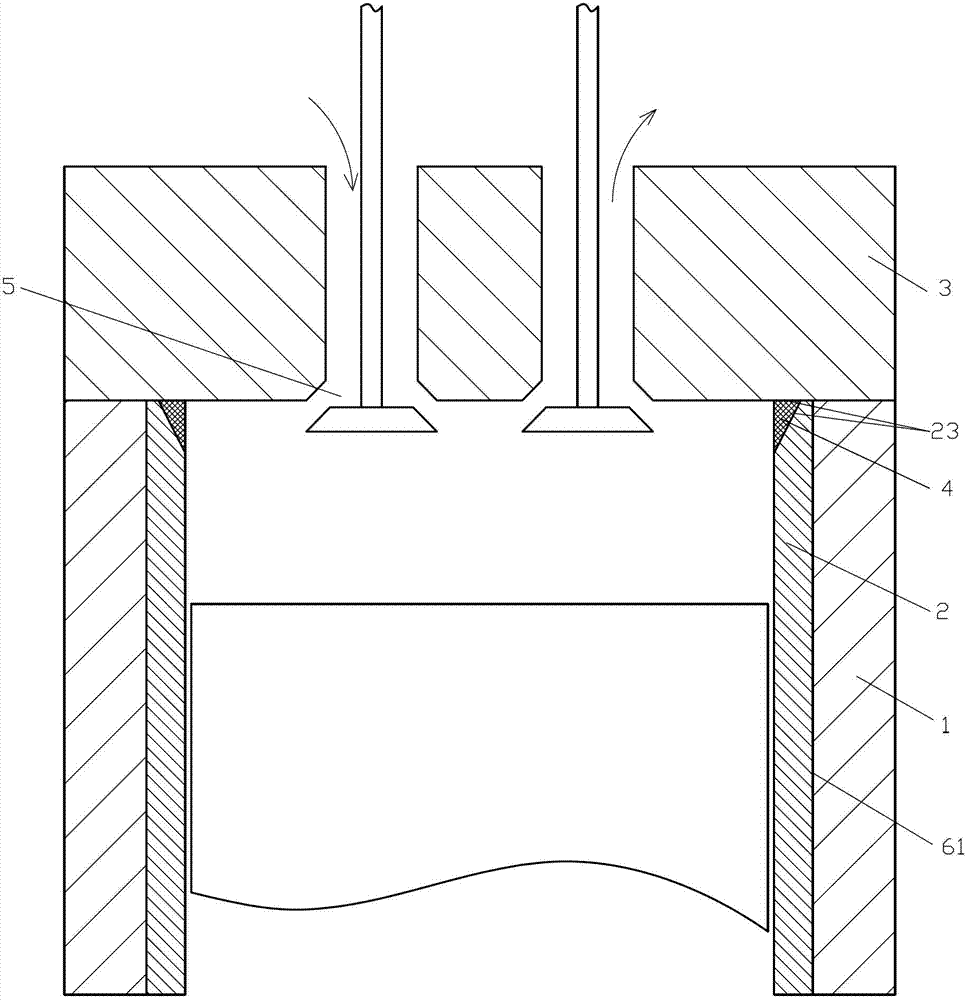

[0044] like figure 1 The cylinder head matching body shown includes a body 1, a cylinder liner 2, a cylinder head 3 and a sealing ring 4. The cylinder liner 2 is arranged in the cylinder hole 61 of the body 1, and the cylinder head 3 passes through the cylinder head Bolts are fixedly connected with the body 1, and the sealing ring 4 is arranged in the cylinder liner 2 and sealingly fits with the inner edge 23 of the mating surface of the cylinder liner 2 and the cylinder head 3. In the cylinder head 3 A gas distribution port 5 is arranged on the top, and a gas distribution valve is arranged at the gas distribution port 5 .

[0045] The high-pressure gas in the cylinder exerts force on the sealing ring 4 arranged in the cylinder, thereby realizing the sealing effect of the sealing ring 4 on the cylinder head 3 and the cylinder liner 2, and further strengthening the cylinder head 3 The seal between the cylinder liner 2 and the cylinder liner 2 greatly reduces the high pre-tigh...

Embodiment 2

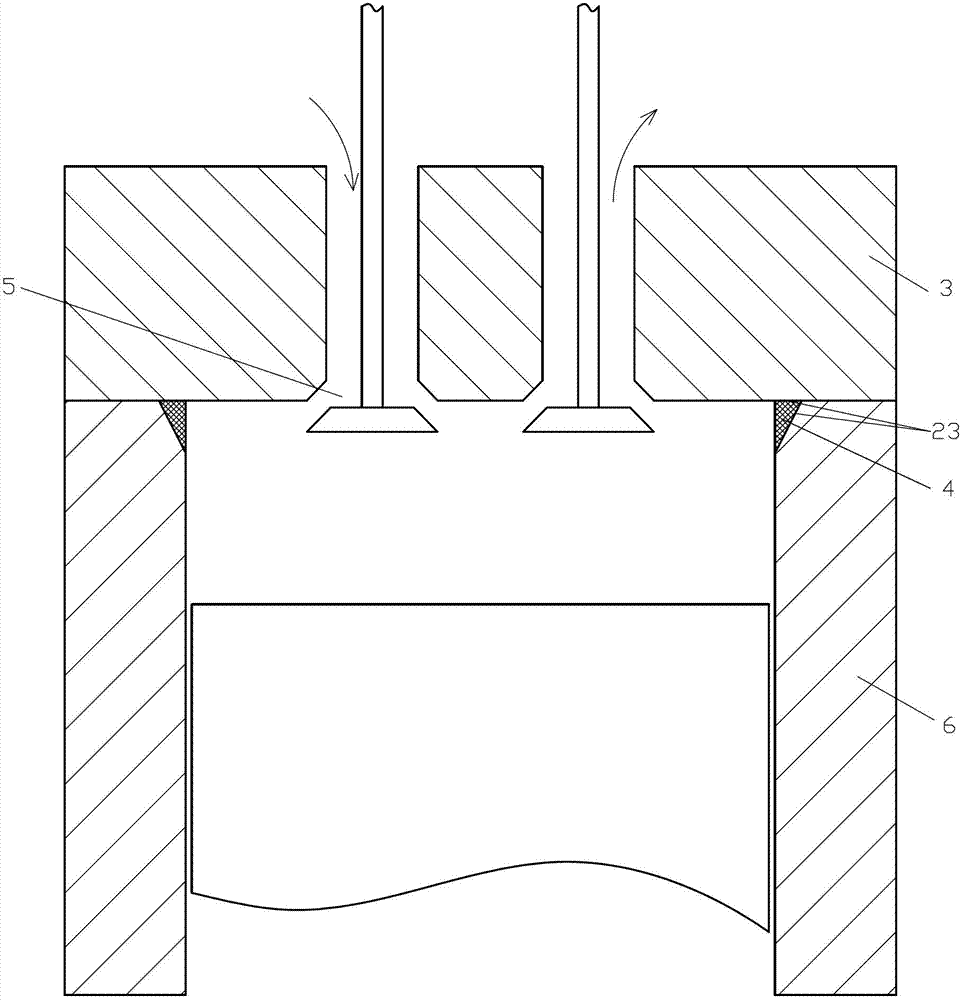

[0047] like figure 2 The difference between the shown cylinder head matching body and the first embodiment is that the body 1 and the cylinder liner 2 are integrated into a body-cover integrated body 6 .

[0048] The high-pressure gas in the cylinder exerts force on the sealing ring 4 arranged in the cylinder, thereby realizing the sealing effect of the sealing ring 4 on the cylinder head 3 and the body-cover integrated body 6, further strengthening the The seal between the cylinder head 3 and the integrated body 6 of the body cover.

Embodiment 3

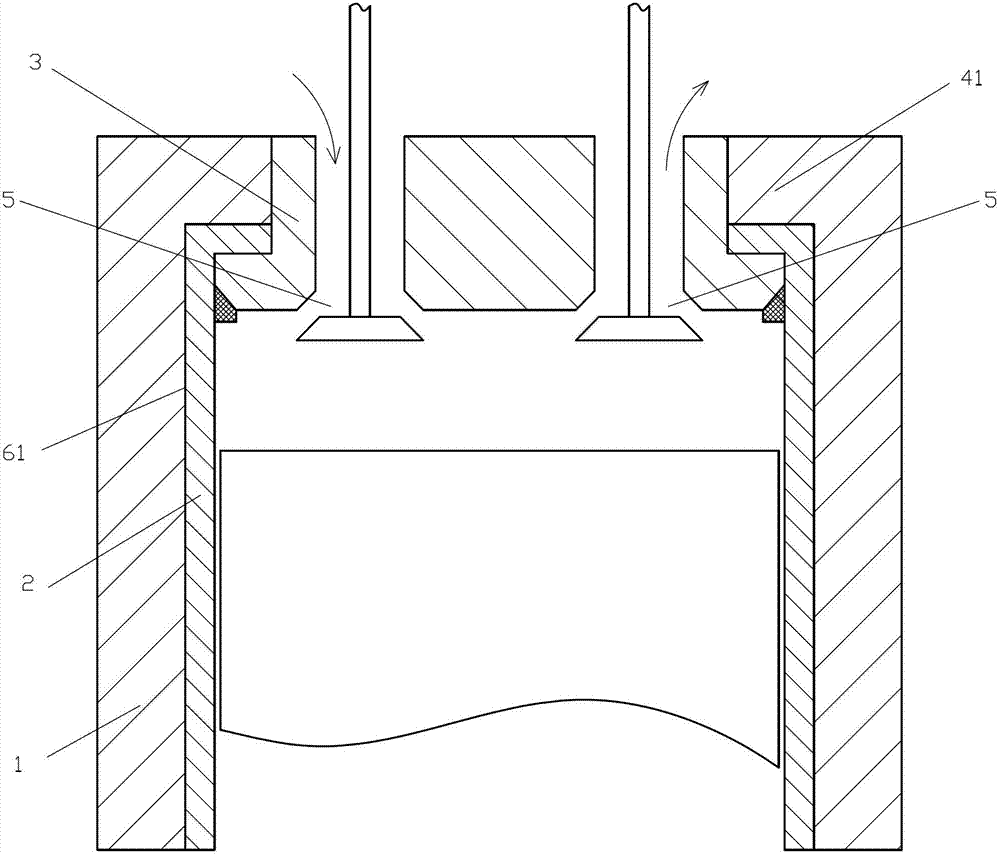

[0050] like image 3 The difference between the illustrated cylinder head matching body and Embodiment 1 is that a sealing load-bearing closing structure 41 is provided at the upper opening of the cylinder bore 61 of the body 1 and at the upper opening of the cylinder liner 2 , so that The sealing and bearing closing structure 41 plays the role of bearing and sealing cooperation.

[0051] The so-called load-bearing sealing fit refers to the fit that plays a sealing role and a load-bearing role at the same time. The purpose of the sealing fit is to prevent the high-temperature and high-pressure gas in the cylinder from leaking between the cylinder head 3 and the sealed load-bearing closing structure 41. The load-bearing is It means that the seal bearing closing structure 41 can withstand the force of the high temperature and high pressure gas in the cylinder on the cylinder head 3 and the sealing bearing closing structure 41 .

[0052] Optionally, a sealing bearing closing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com