Engineering mechanical hydraulic oil tank, control method thereof and engineering machine

A technology for construction machinery and hydraulic oil tanks, which is applied in mechanical equipment, oil supply tank devices, fluid pressure actuators, etc., can solve problems such as acceleration equipment, oil suction difficulties of oil pumps, and hydraulic actuators, and achieve fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

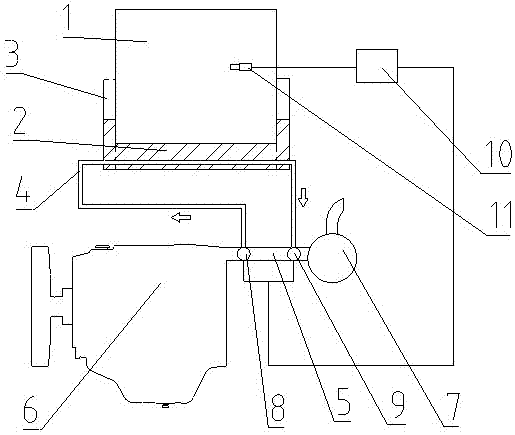

[0015] Such as figure 1 As shown, the present invention is an embodiment of a construction machinery hydraulic oil tank, which includes a fuel tank body 1, and the fuel tank body 1 is covered with a cavity 3 filled with a liquid or gaseous heating medium 2, which is made of a good conductor of heat The formed gas pipeline 4 passes through the cavity 3, the air inlet of the gas pipeline 4 is connected to the first branch pipe of the exhaust pipe 5 near the engine 6, and the gas outlet of the gas pipeline 4 is connected to the exhaust pipe 5 near the discharge port On the second branch pipe at 7, the first branch pipe is provided with a first valve switch 8 that controls whether the gas in the exhaust pipe flows into the first branch pipe, and the second branch pipe is provided with a valve switch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com