Method for manufacturing a uniform-density vacuum insulated panel with high production efficiency

A technology for vacuum insulation panels and production efficiency, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc. It can solve the problems of easily damaged core material corner forming, inability to ensure core material uniformity, and low degree of automation. Achieve high degree of equipment automation, ensure stability, and solve processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

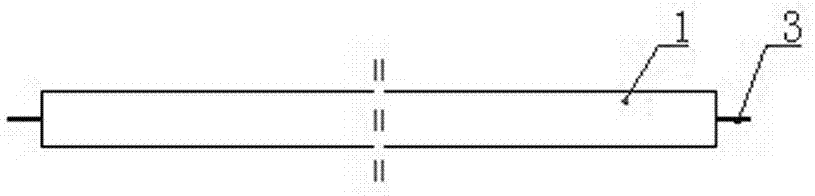

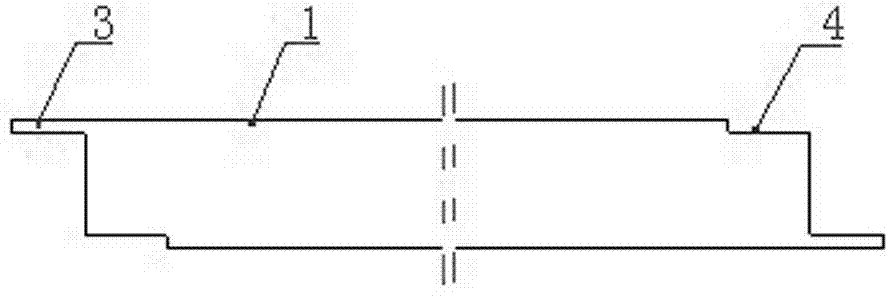

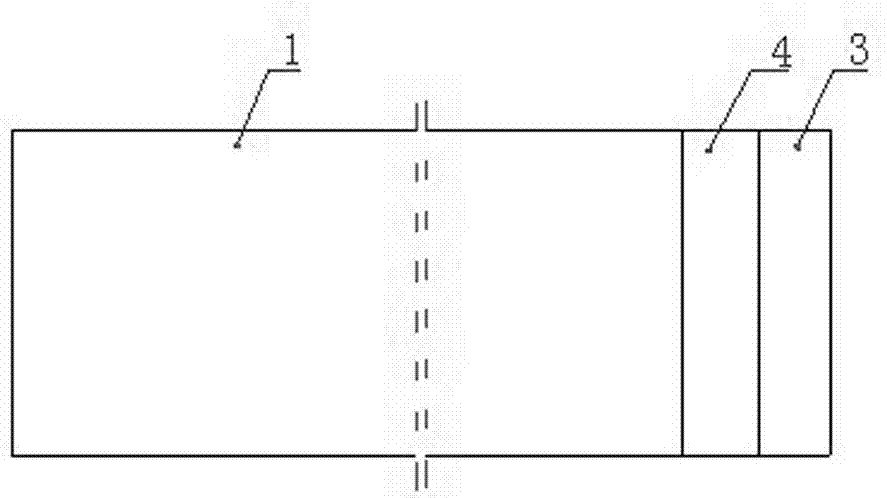

[0024] A method for manufacturing a vacuum insulation panel with uniform density and high production efficiency according to the present invention is characterized in that it comprises the following process steps:

[0025] (1) Use a bag making machine to make a non-woven bag of a specified size, seal three sides, and leave one side unsealed. The sealing adopts the method of ultrasonic sealing. A machine that uses ultrasonic concentrators to act on the sealing part of the packaging container to seal the packaging container. Ultrasonic energy is transmitted to the welding area through the upper weldment. Due to the large acoustic resistance in the welding area, that is, the interface between the two welds, local high temperature will be generated. Due to the poor thermal conductivity of the non-woven fabric, it cannot be dissipated in time for a while, and it gathers in the welding area, causing the contact surface of the two non-woven fabrics to melt rapidly, and after a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com