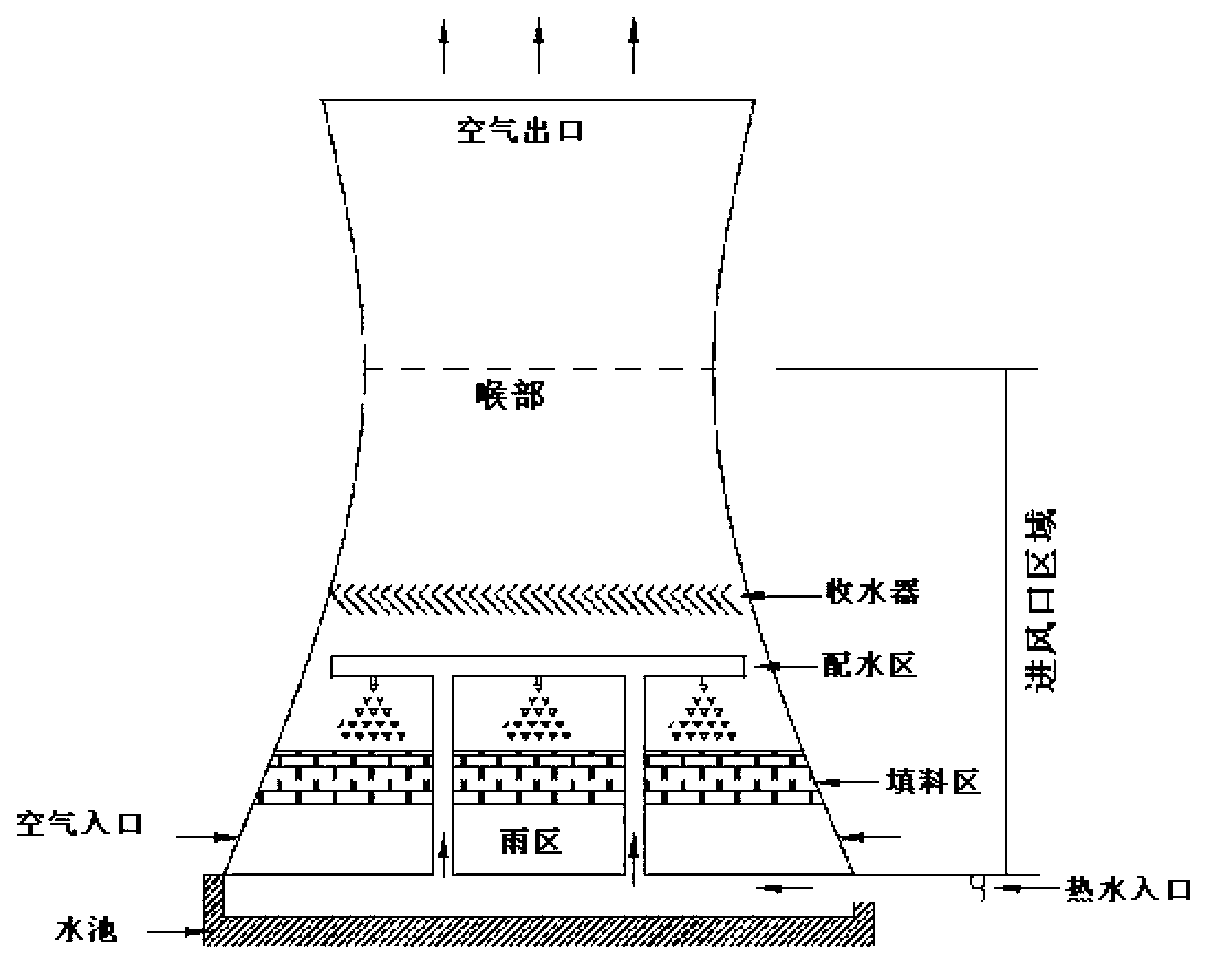

Method and system for designing ultra-large reverse-flow natural ventilation wet cooling tower

A natural ventilation and wet cooling technology, which is applied in the direction of water shower coolers, calculations, heat exchanger types, etc., can solve problems such as small and large cooling towers, and achieve safety issues, operational stability and safety The effect of reliable guarantee and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

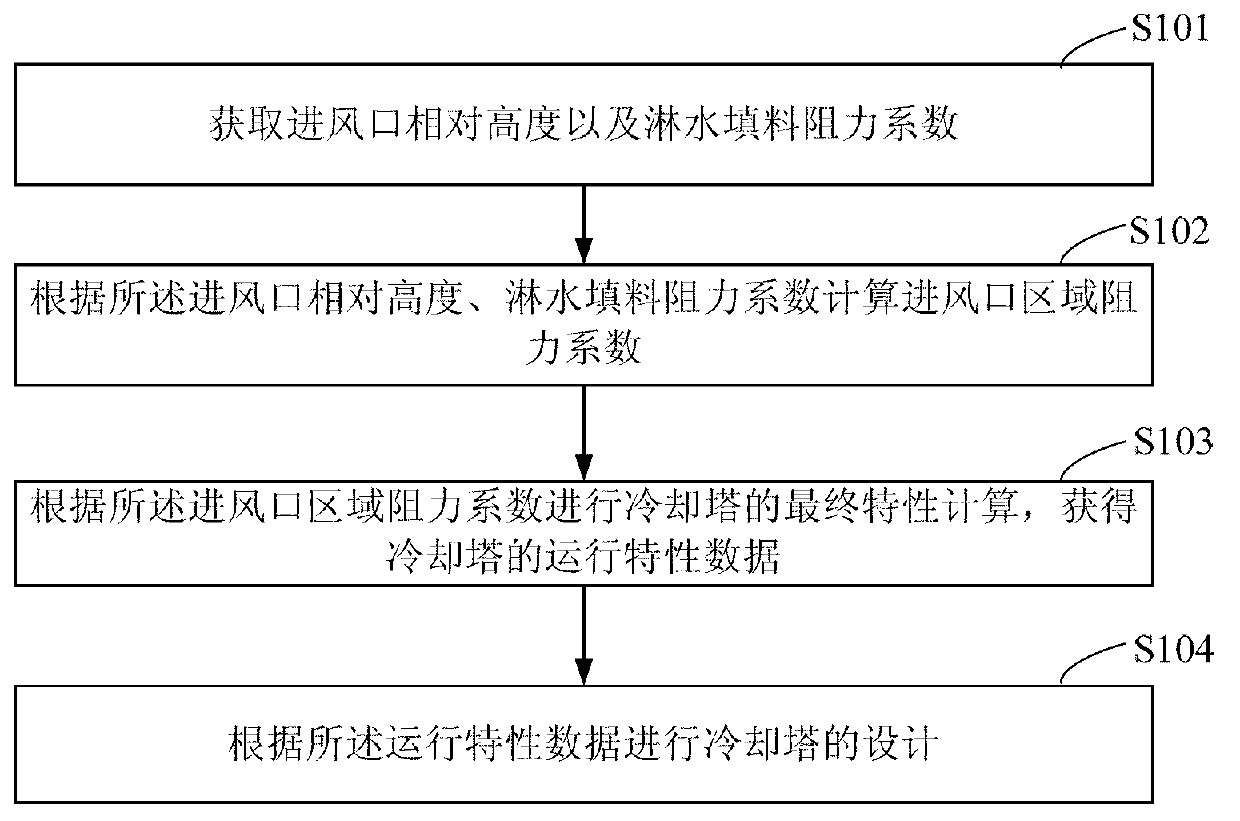

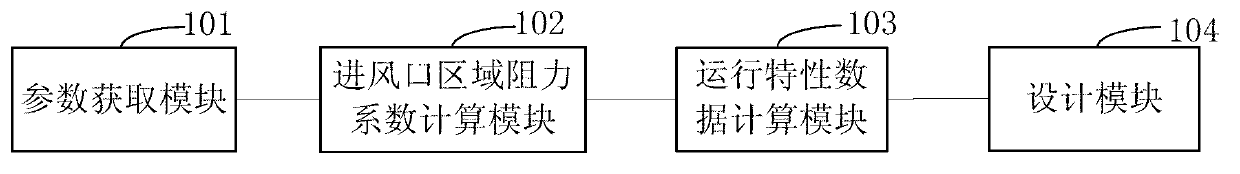

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] see figure 1 As shown, a design method of a super-large counterflow natural draft wet cooling tower includes the following steps:

[0033] Step S101, obtain the relative height of the air inlet (denoted as ε) and the resistance coefficient of the water spray filling (denoted as ξ f ), and then enter step S102.

[0034] Step S102, according to the relative height of the air inlet (ε), the resistance coefficient of the water spray filler (ξ f ) and use the following formula to calculate the resistance coefficient of the air inlet area (denoted as ξ a ):

[0035] ξ a = ( 76.65 - 261.33 ε + 264.85 ε 2 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com