Grease for electrical contact and slide electricity structure, power switch, vacuum circuit breaker, vacuum-insulated switchgear assembling method

A switchgear, vacuum insulation technology, applied in the direction of switchgear, switchgear setting, high-voltage air circuit breaker, etc., can solve the problems of increasing contact resistance, low conductivity passivation film, shortening service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

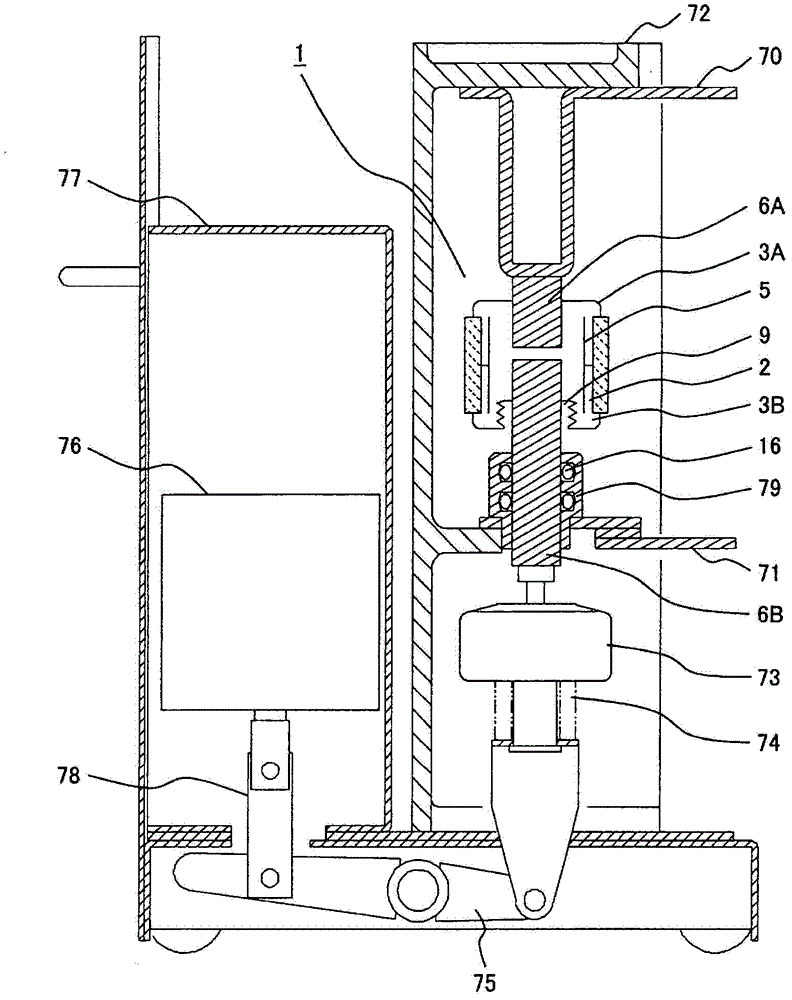

[0023] figure 1 An example of a vacuum circuit breaker will be shown as the first embodiment of the sliding conduction structure to which the grease for electrical contacts of the present invention is applied.

[0024] As shown in the figure, a vacuum circuit breaker generally includes: a vacuum valve 1 having at least one pair of contact points that can be brought into contact or separated from each other; a fixed-side terminal 70 and a movable-side terminal 71 connected to the vacuum valve 1; An insulating cylinder 72; an insulating operating rod 73 connected to the movable side electrode 6B of the vacuum valve 1; a wiping (wipe mechanism) mechanism 74 for applying contact force to the movable side electrode 6B and the fixed side electrode 6A of the vacuum valve 1; An operator 76 that generates an operating force; an operating lever 78 connected to the operator 76; a main lever 75 that connects the operating lever 78 to the wiping mechanism 74; and a housing 77 that accommod...

Embodiment 2

[0047] Figure 4 An example of a vacuum insulated switchgear as a second embodiment of the sliding current structure to which the grease for electric contacts of the present invention is applied is shown.

[0048] As shown in the figure, the vacuum insulated switchgear uses the solid insulator 30 to collectively cast the busbar bushing center conductor 41, the vacuum valve 1, the cable bushing center conductor 43, the earthing breaker bushing side fixed electrode 11, etc. , by combining with the movable electrode 12 of the grounding breaking part that moves linearly in the atmosphere, the grounding breaking part 10 that switches the on state, the grounding state and the disconnecting state is constituted. In addition, in this embodiment, for the sake of illustration, it is configured to be able to switch the three positions of on, ground, and disconnected, but if it is a switch with a slide conduction structure, it may also be configured to be able to switch between two positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com