Semiconductor manufacturing device and manufacturing method thereof

A technology for manufacturing devices and manufacturing methods, applied to semiconductor manufacturing devices and manufacturing fields, capable of solving problems such as increased power usage and reduced signal transmission speed of semiconductor components, and achieving the effects of preventing increased power usage, reducing signal transmission speed, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

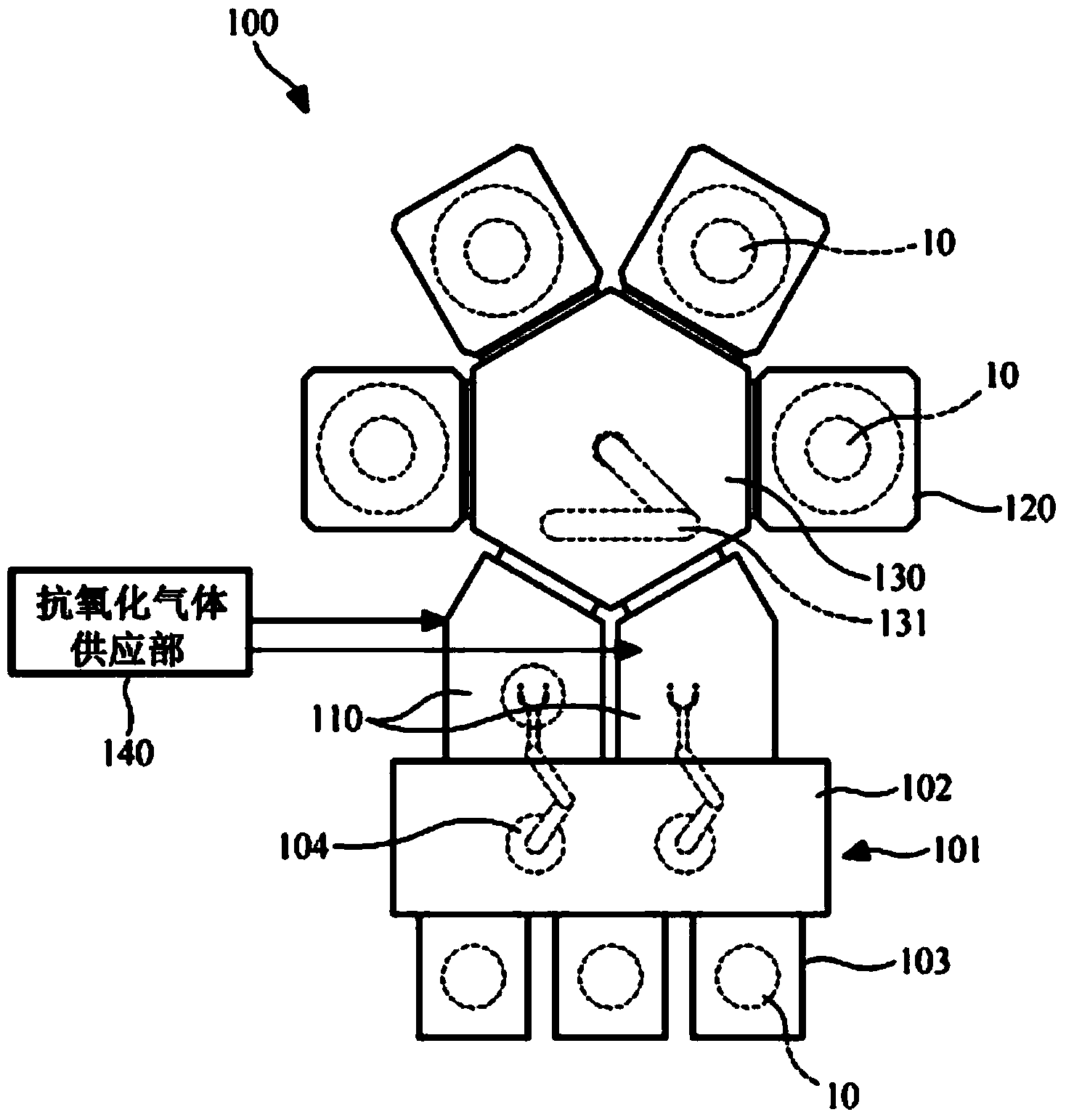

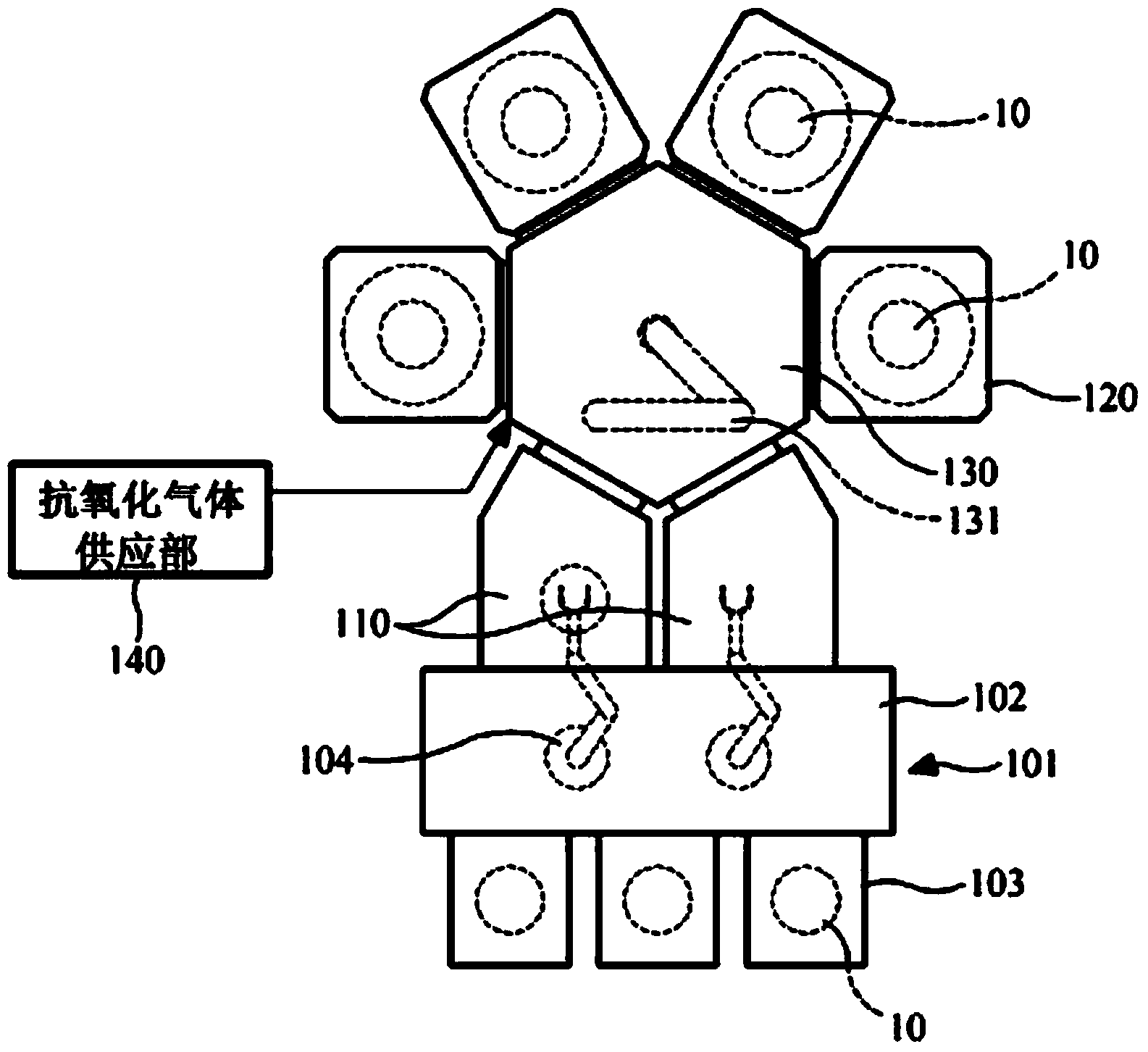

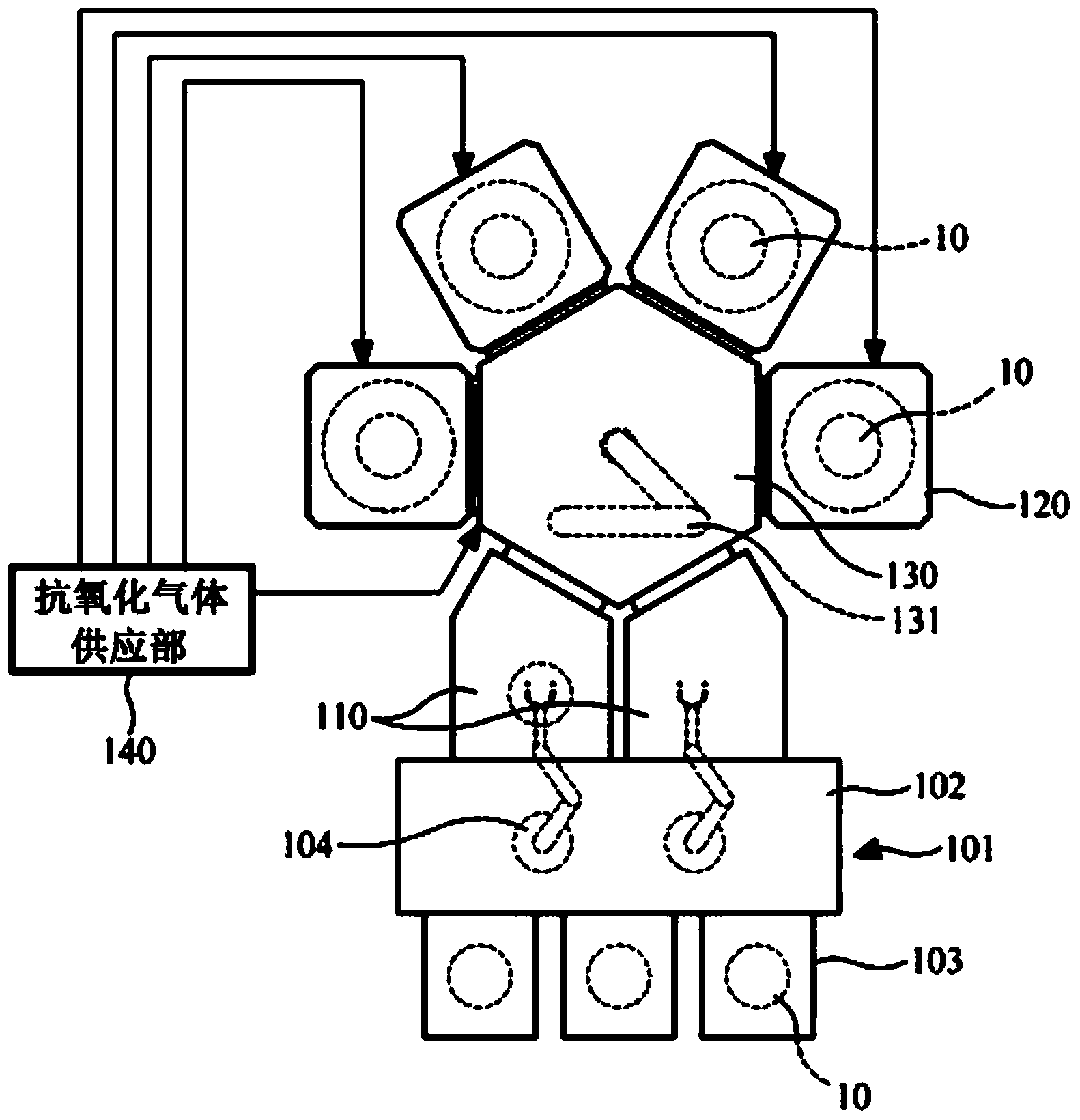

[0020] figure 1 is a configuration diagram of a semiconductor manufacturing apparatus according to a first embodiment of the present invention. refer to figure 1 As shown, the semiconductor manufacturing apparatus 100 includes: a loading chamber 110 ; at least one processing chamber 120 ; a transfer chamber 130 ; and an anti-oxidation gas supply part 140 .

[0021] The carrier chamber 110 accommodates the substrate 10 in a state where the vacuum environment of the processing chamber 120 is kept consistent with the actual state before the substrate 10 such as a wafer is sent into the processing chamber 120 outside the atmospheric pressure environment, or the transfer chamber 130 carries the substrate 10 to the outside. Before sending out, the substrate 10 is housed in a state substantially equal to the external atmospheric pressure environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com