Medium voltage winding cable for electric generator, motor and transformer

A winding and cable technology, applied in the field of new electrical materials, can solve the problems of lack of metal shielding and sheath, poor mechanical strength and insufficient flexibility of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

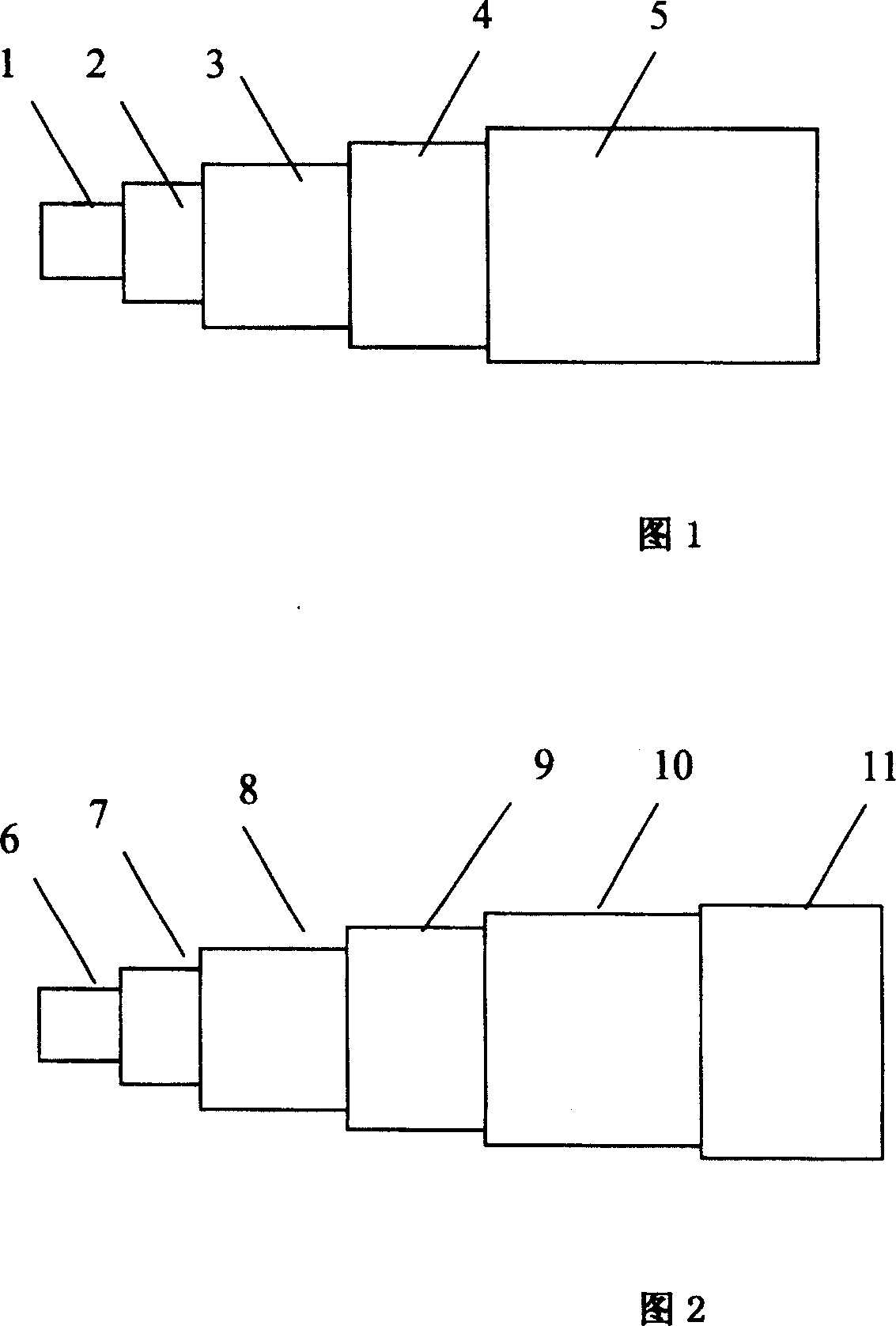

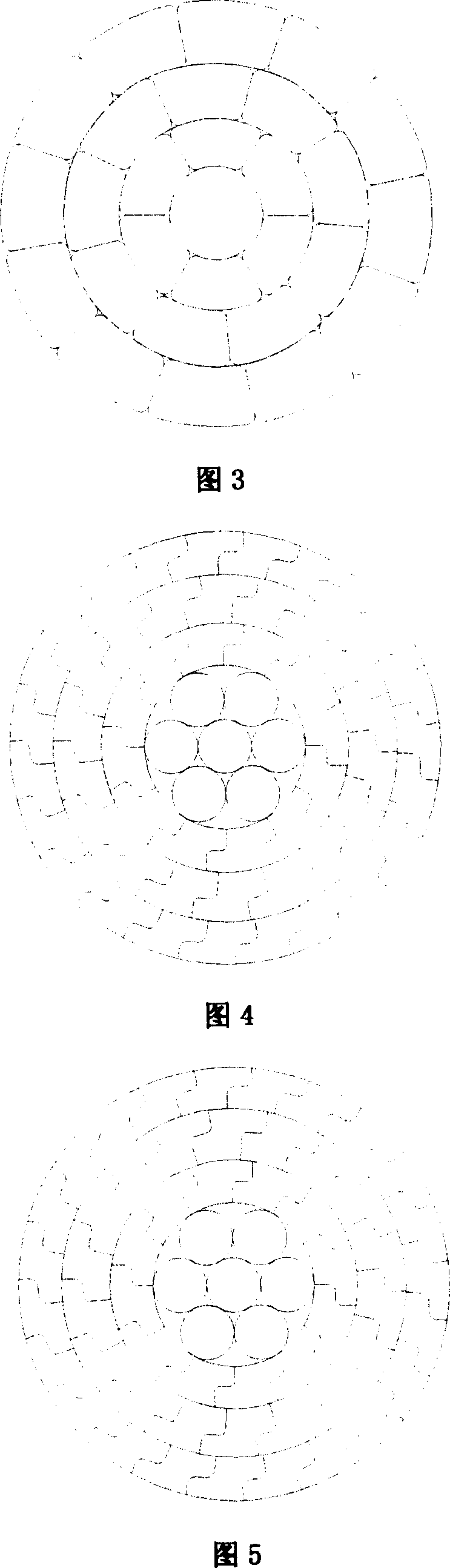

[0019] Example 1: Medium Voltage Long Stator Winding Cable Used as Magnetic Suspension

[0020] Rated voltage -10kV

[0021] The conductor is made of 60 annealed aluminum wires, which are divided into 5 layers and twisted tightly. The stranding directions of adjacent layers are opposite, and the compression coefficient is 91%. And annealed in a heating furnace, the conductivity is 62% IACS.

[0022] Conductor shielding and insulating shielding are the same, and the formula components are 90 parts of EPDM, 10 parts of ethylene-vinyl acetate copolymer, 5 parts of lubricant, 2.5 parts of crosslinking agent, 70 parts of conductive carbon black, 1.5 parts of anti-aging agent, 20 parts processing oil. Its volume resistivity at 20°C is 1.0Ω·m, and its elongation at break exceeds 400%.

[0023] The insulation formula components are 90 parts of EPDM, 10 parts of ethylene-vinyl acetate copolymer, 5 parts of lubricant, 2.5 parts of crosslinking agent, 60 parts of calcined clay, 1.5 pa...

Embodiment 2

[0029] Example 2: Winding cable used as a transformer

[0030] Rated voltage -10kV

[0031] The conductors are stranded in 5 layers, the inner two layers are copper round wires, and the outer three layers of aluminum conductors have a Z-shaped section, and the adjacent layers are twisted in opposite directions, and are annealed in a heating furnace.

[0032] Conductor shielding and insulating shielding are the same, and the formula components are 70 parts of EPDM, 30 parts of ethylene-vinyl acetate copolymer, 10 parts of lubricant, 3 parts of crosslinking agent, 90 parts of conductive carbon black, 2 parts of anti-aging agent, 15 parts of processing oil.

[0033] The insulation formula components are 70 parts of EPDM, 30 parts of ethylene-vinyl acetate copolymer, 10 parts of lubricant, 3 parts of crosslinking agent, 80 parts of calcined clay, 2 parts of anti-aging agent, and 15 parts of processing oil.

[0034] The conductive sheath formula consists of 100 parts of rubber, 1...

Embodiment 3

[0036] Example 3: Cables used as generator windings

[0037] Rated voltage -35kV

[0038] The conductor is stranded in 4 layers using soft copper wires, the outer 2 layers of aluminum wires have a tile-shaped cross-section, and the stranding directions of adjacent layers are opposite, and are annealed in a heating furnace.

[0039] Conductor shielding and insulating shielding are the same, and the formula components are 80 parts of EPDM, 20 parts of ethylene-vinyl acetate copolymer, 3 parts of lubricant, 4 parts of crosslinking agent, 60 parts of conductive carbon black, 3 parts of anti-aging agent, 10 parts processing oil.

[0040] The insulation formula consists of 80 parts of EPDM, 20 parts of ethylene-vinyl acetate copolymer, 3 parts of lubricant, 4 parts of crosslinking agent, 70 parts of calcined clay, 3 parts of anti-aging agent, and 10 parts of processing oil.

[0041] The conductive sheath formula consists of 100 parts of rubber, 7 parts of metal oxide active agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com