Silver coating material and method for manufacturing same

A technology of coating material and manufacturing method, applied in contact materials, contacts, electrical components, etc., can solve the problems of deterioration of wear resistance and brittle film, and achieve the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

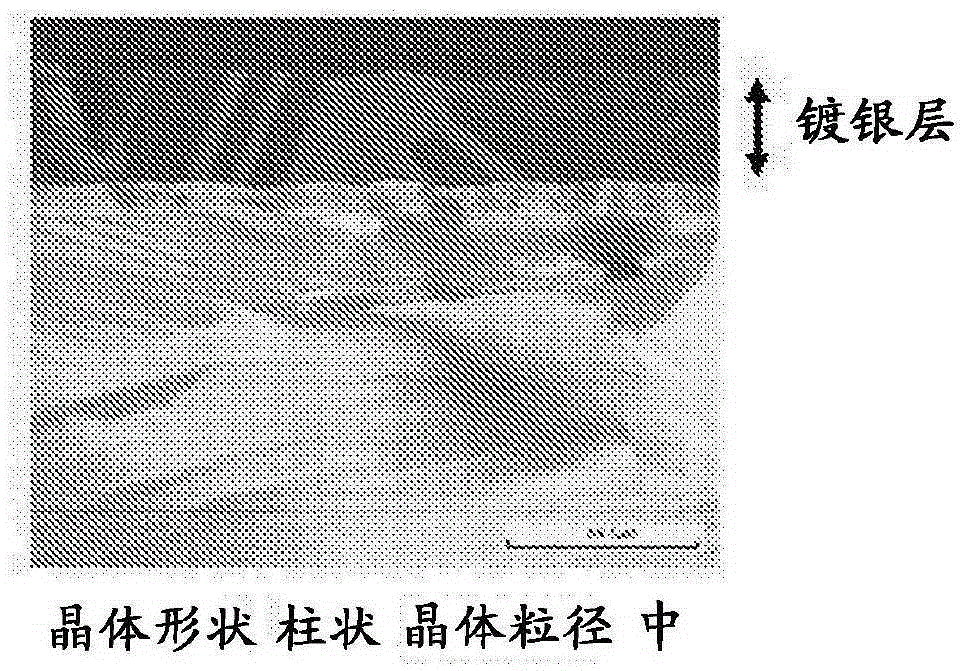

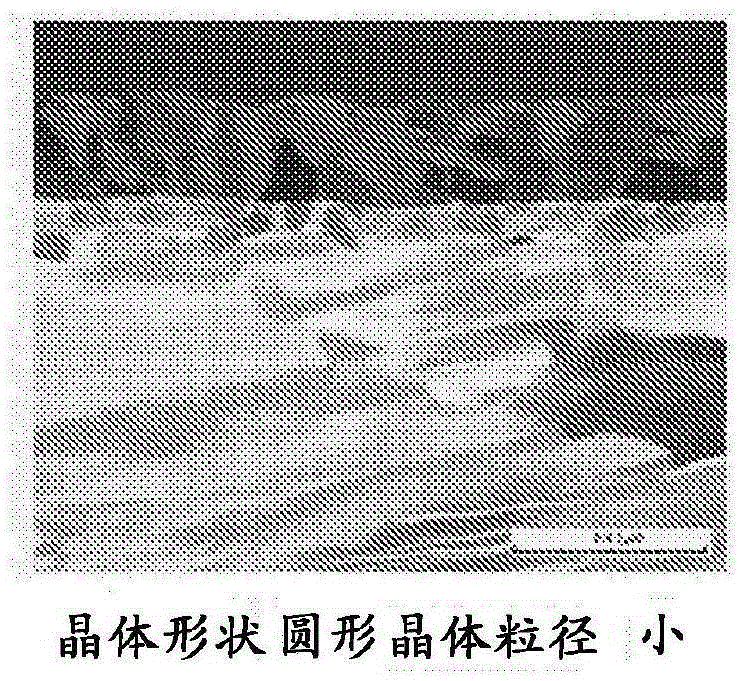

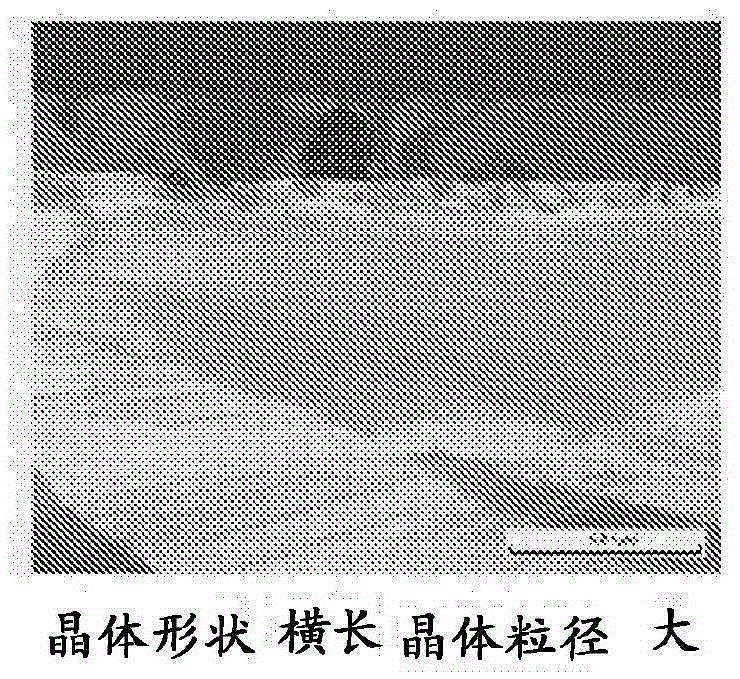

Image

Examples

Embodiment 1

[0070] Phosphor bronze (C5210, 25mm×20mm×thickness 0.2mm) is sequentially plated to form a 0.05μm thick silver strike layer and a 0.4μm thick silver layer obtained by plating with a high-cyanide silver bath. The plated substrate was used as the test material.

[0071] Under the conditions of Example 1 in Table 1, the above-mentioned plated substrate was heat-treated using a hot plate in the air. The heat treatment temperature is a temperature obtained by measuring the temperature of the plated substrate placed on the heating plate with a thermocouple.

Embodiment 2 and Embodiment 3

[0073] Phosphor bronze (C5210, 25mm×20mm×thickness 0.2mm) is sequentially plated to form a 3μm thick copper plating layer obtained by copper cyanide bath plating, a 0.05μm thick silver strike plating layer, and a 0.4μm thick The silver-plated layer obtained by high-cyanide silver bath plating is used as the test material.

[0074] Under the conditions of Example 2 and Example 3 in Table 1, the above-mentioned plated substrate was heat-treated using a hot plate in the air.

Embodiment 4

[0076] Phosphor bronze (C5210, 25mm×20mm×thickness 0.2mm) is sequentially plated to form a 3μm-thick nickel plating layer obtained by sulfamic acid bath plating, a 0.05μm-thick silver strike plating layer, and a 0.4μm-thick The silver-plated layer obtained by high-cyanide silver bath plating is used as the test material.

[0077] Under the conditions of Example 4 in Table 1, the above-mentioned plated substrate was heat-treated using a hot plate in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average crystal size | aaaaa | aaaaa |

| Average crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com