Display device and method for production thereof

A technology for a display device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of surface oxidation, inability to improve display quality, and unavoidable increase in energy consumption for auxiliary wiring, and achieve low energy consumption. consumption and improve display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

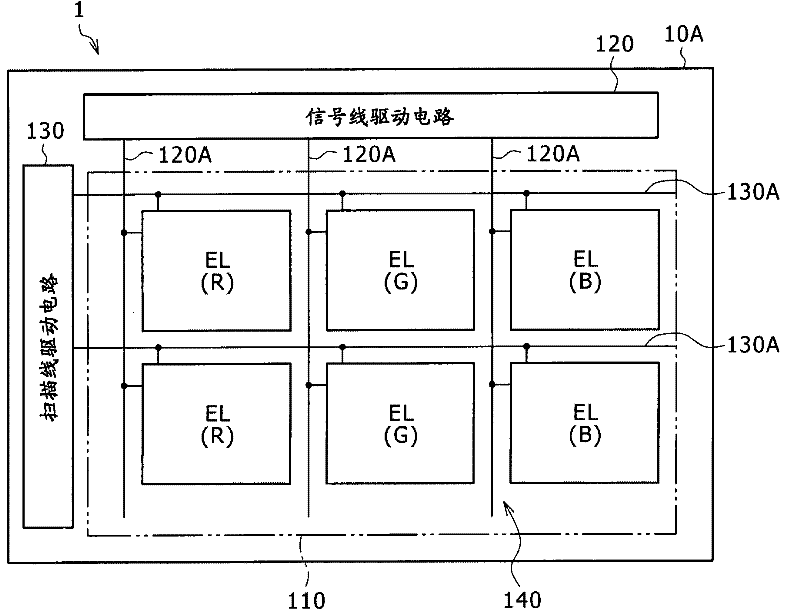

[0050] figure 1 is a view showing the structure of the display device (organic EL display device) of the first embodiment of the present invention. The organic EL display device 1 is a display device serving as an extremely thin organic color display device. The organic EL display device 1 includes a transparent substrate 10A and a plurality of organic EL elements (EL) arranged in a matrix on the transparent substrate 10A, thereby forming a display area 110 . The organic EL display device 1 also has a signal line driver circuit 120 and a scan line driver circuit 130 (both for displaying images) formed along the sides of the display region 110 .

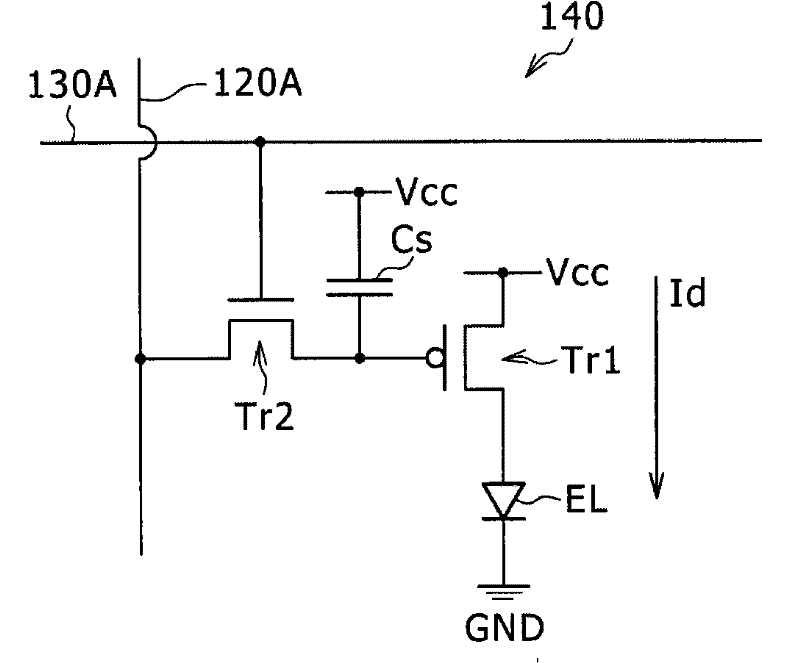

[0051] The display area 110 has a pixel driving circuit 140 formed therein. figure 2 is a view showing an example of the pixel driving circuit 140 . The pixel drive circuit 140 is an active type drive circuit formed under the first electrode 18A (to be described later), and includes a drive transistor Tr1, a write transistor Tr2,...

no. 2 example

[0100] A display device according to a second embodiment of the present invention will be described below. Constituent elements common to the first embodiment and the second embodiment are denoted by the same symbols, and their descriptions will not be repeated.

[0101] Figure 11 is a cross-sectional view showing the structure of the contact portion 25B of the display device (organic EL display device) of this embodiment. At the bottom of the contact portion 25B, there is a low-resistance wiring layer 26 on the transparent substrate 11A, and the low-resistance wiring layer 26 is on the same layer as the source signal line or the gate wiring connected to the thin film transistor Tr. The low-resistance wiring layer 26 has a thickness of 500 nm, and on the low-resistance wiring layer 26, the gate electrode 11, the gate insulating film 12, the silicon film 13A, the barrier insulating film 14 and n + type amorphous silicon film 13B. The low-resistance wiring layer 26 can preve...

no. 3 example

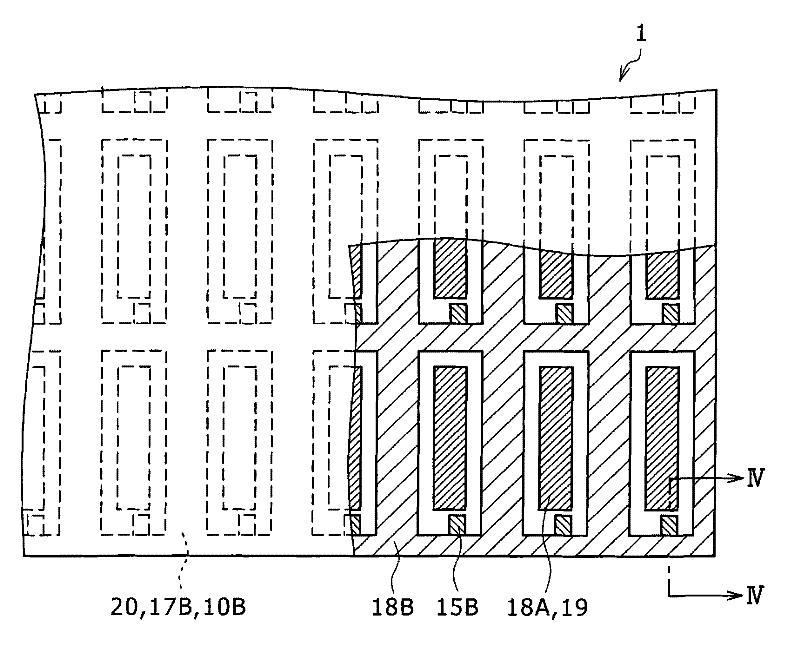

[0112] Figure 14 is a view showing the planar structure of the display region 110 of the organic EL display device 1 of the third embodiment of the present invention. Figure 15 is along Figure 14 Cross-sectional view taken along line XV-XV in . This organic EL display device 1 has the same structure as the organic EL display device of the first embodiment described above except that the auxiliary wiring 15C has the same layered structure as the contact portion 15B and is integrally formed with the contact portion 15B. Accordingly, corresponding constituent elements are denoted by the same reference numerals.

[0113] The present embodiment is similar to the first embodiment in that transparent substrates 10A and 10B, thin film transistor Tr, wiring layer 15A, contact portion 15B, protective insulating film 16, planarizing insulating film 17A, electrode insulating The film 21, the sealing resin 17B, and the organic EL element (EL).

[0114] The auxiliary wiring 15C is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com