Power generation device following up spindle of propeller

A technology for power generation devices and propellers, applied in the directions of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. The problems of large volume and weight can achieve the effect of facilitating power supply, improving power generation capacity and reliability, and strong adaptability to speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

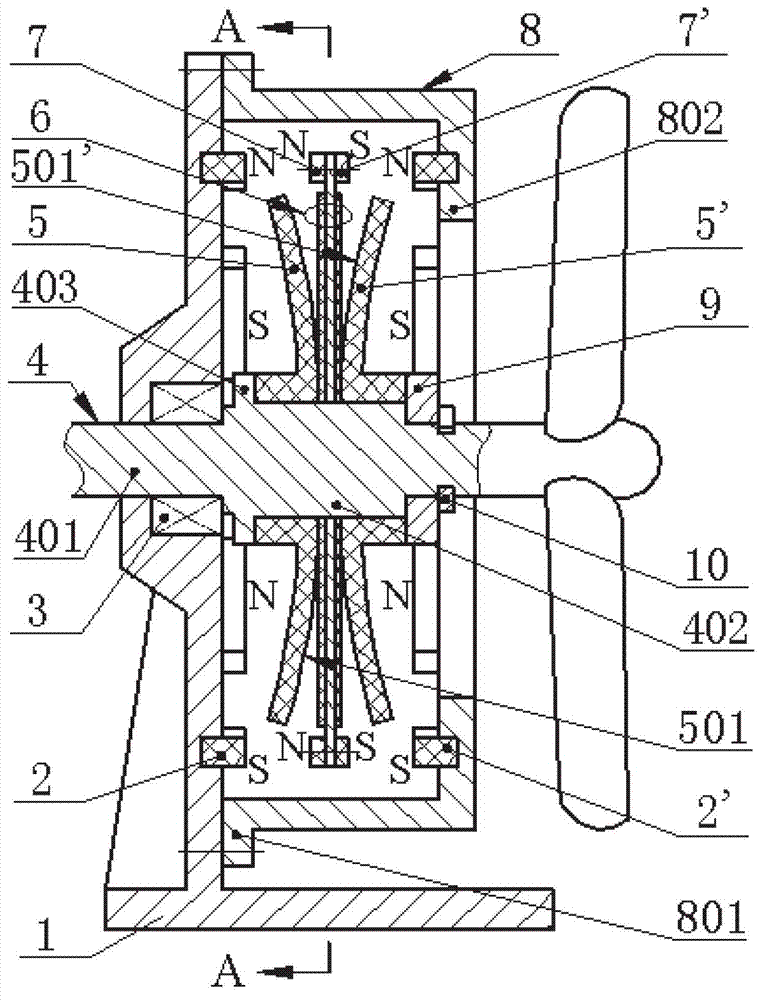

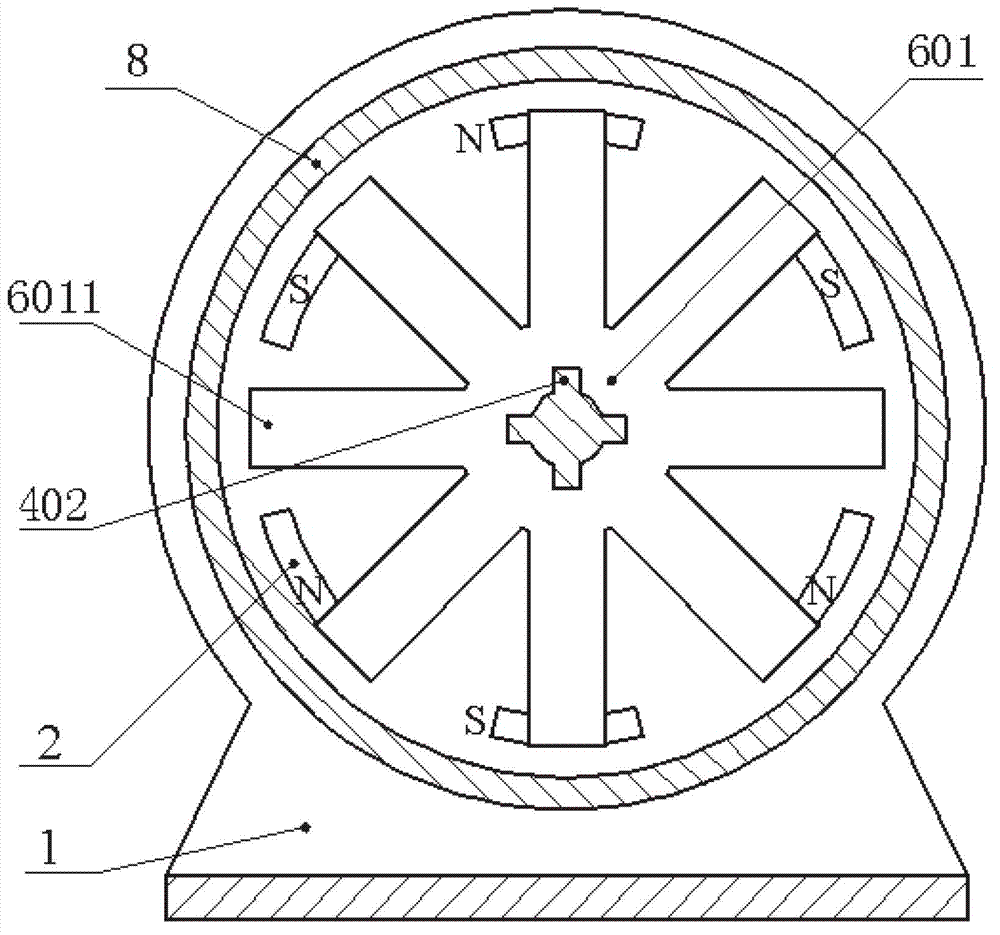

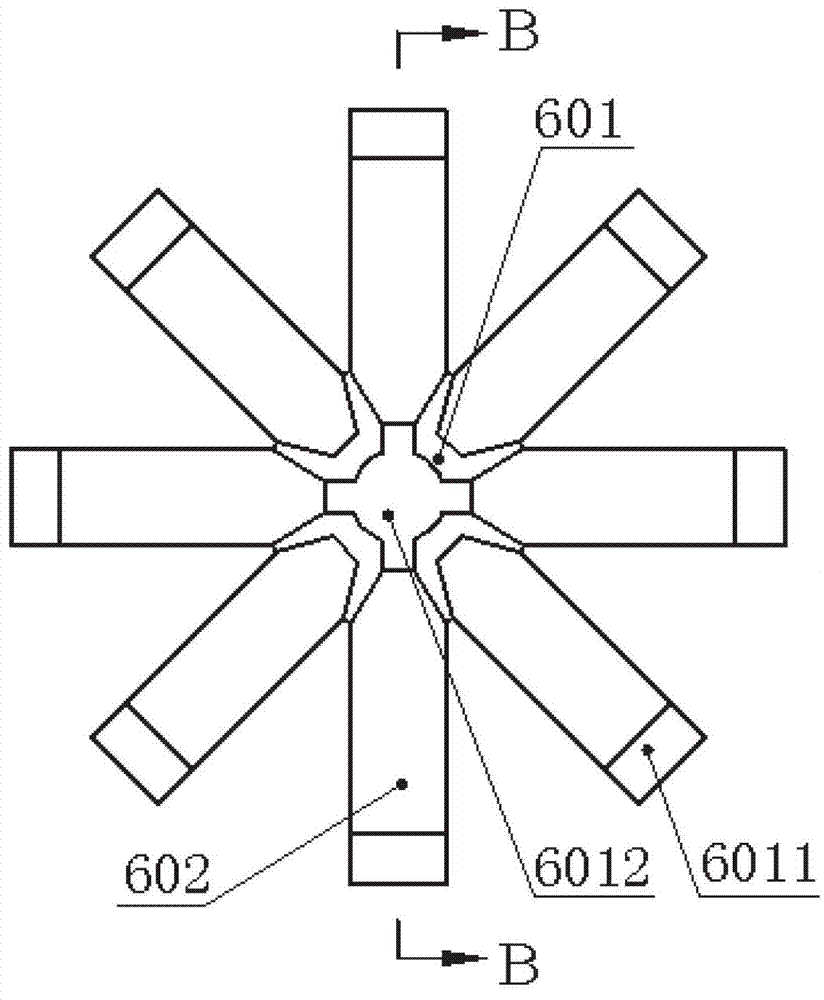

[0015] The side wall of the bearing seat 1 is inlaid with a fixed magnet 2 and a bearing 3; one end 401 of the propeller main shaft 4 is installed on the side wall of the bearing seat 1 through the bearing 2, and the spline 402 of the propeller shaft 4 is sequentially covered with a limit Ring 1 5, piezoelectric transducer 6 and limit ring 2 5', the limit ring 1 5, piezoelectric transducer 6 and limit ring 2 5' are crimped by circlip 10 and retaining ring 9 On the shoulder 403 of the propeller main shaft 4, and the piezoelectric transducer 6 is located between the convex curved surface 501 of the first limiting ring 5 and the convex curved surface 501' of the second limiting ring 5'; The piezoelectric transducer 6 is formed by bonding a cantilever beam 6011 on a metal substrate 601 and a piezoelectric wafer 602, and the symmetrical center of the metal substrate 601 is provided with a spline hole 6012; the first moving magnet 7 and the second moving magnet 7 'Fixed on the free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com