Tire testing apparatus having adjustable bead width

A bead width and testing machine technology, which is applied in the testing of automobile tires, mechanical equipment, vehicles, etc., can solve problems such as tire deformation and affect test results, and achieve the effect of simplifying construction and operation and expanding the range of travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

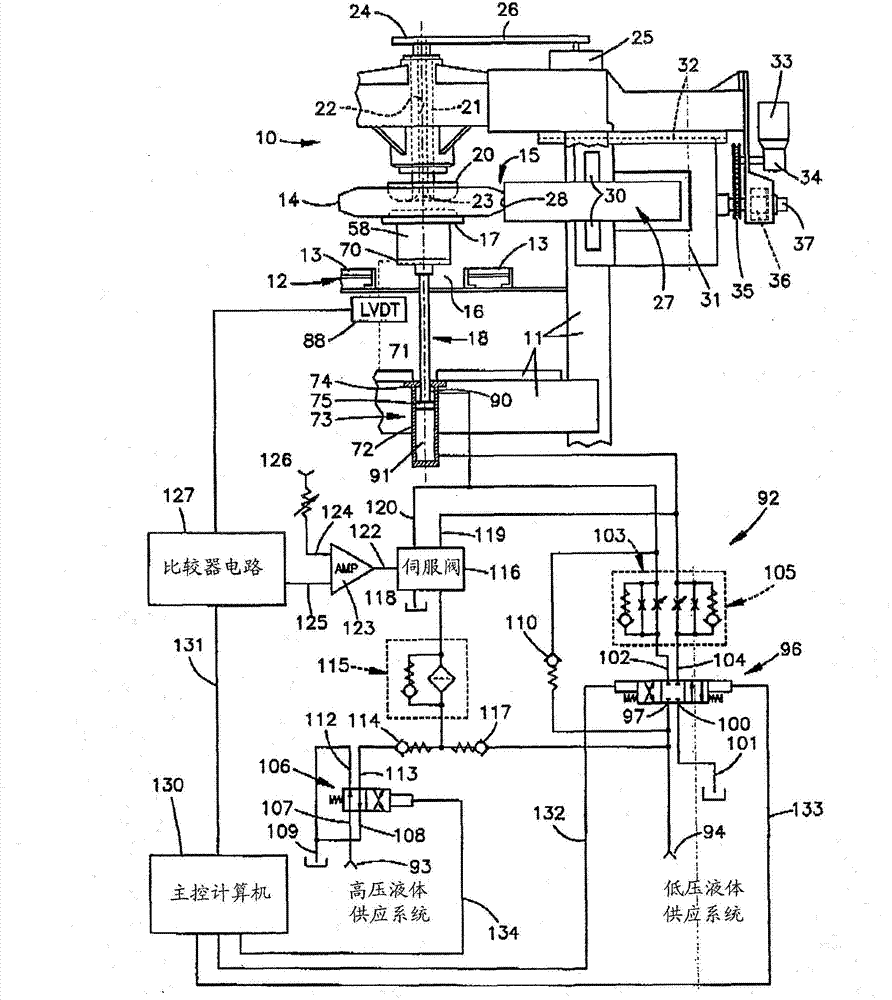

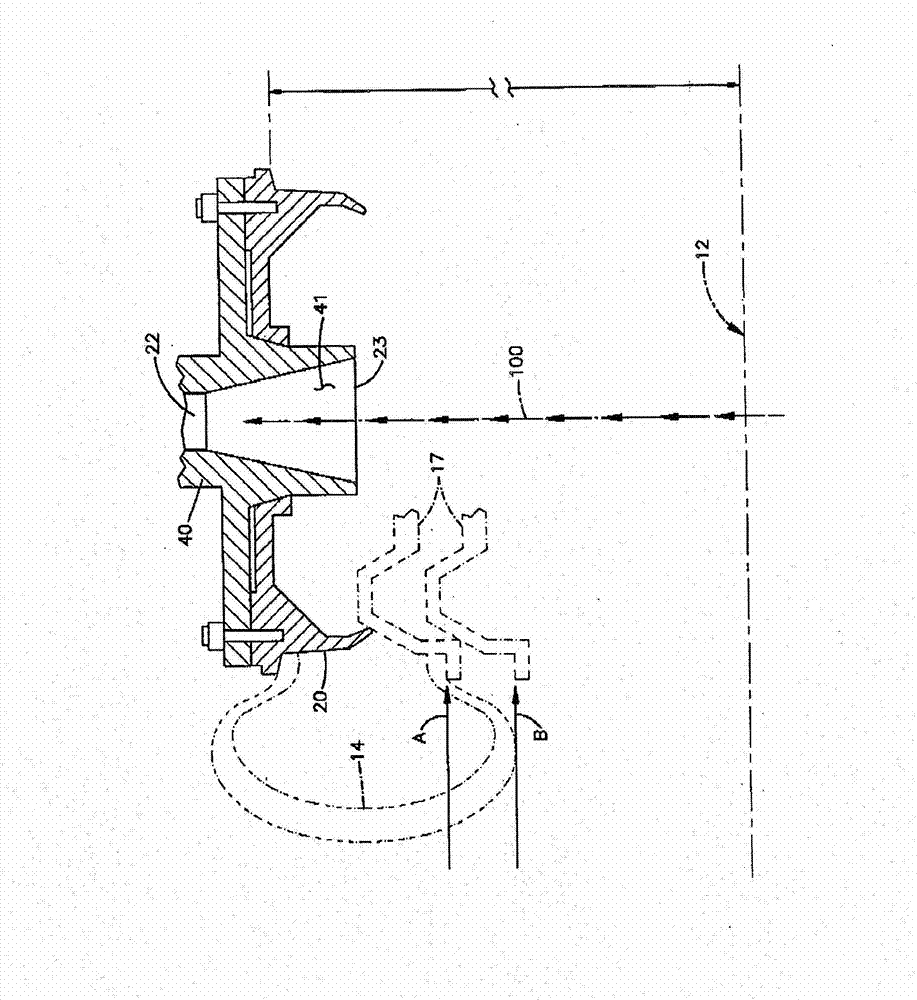

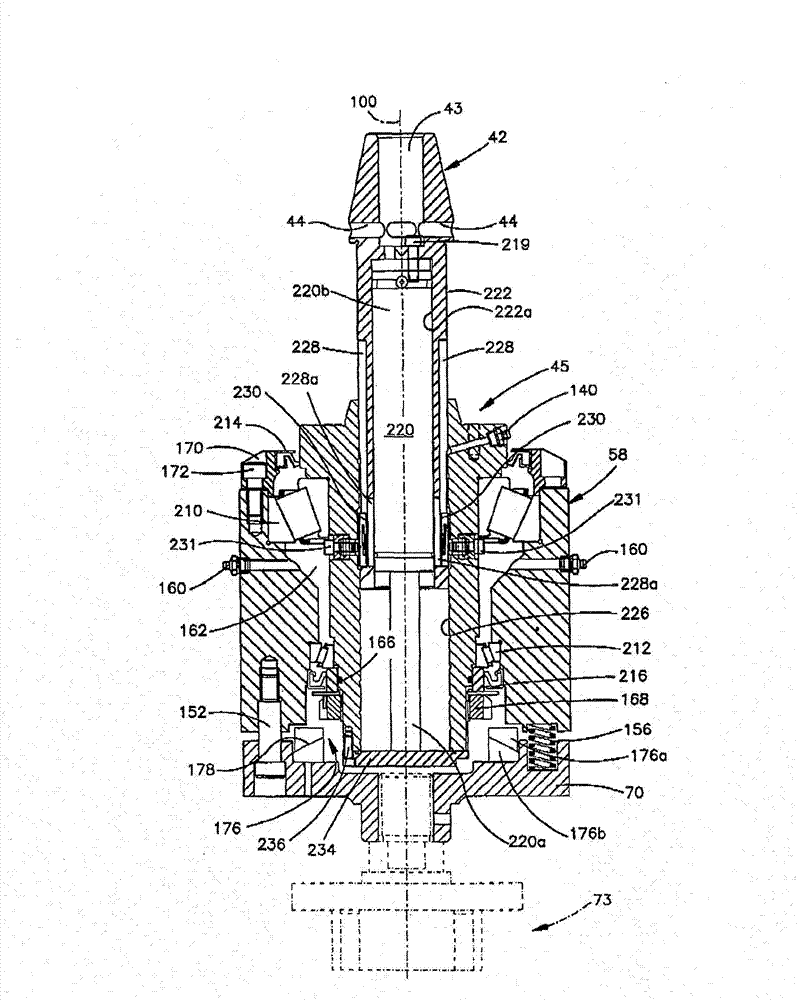

[0015] figure 1 A tire uniformity testing machine 10 is shown which includes a tire clamp / grip device constructed in accordance with the present invention. The testing machine 10 also includes a frame 11 supporting a conveyor 12 comprising a plurality of rollers 13 for transporting tires 14 to be tested to a testing station 15 . A detailed description of the conveyor 12 is found in US Patent No. 4,846,334, which is incorporated herein by reference in its entirety. Conveyor 12 includes an opening 16 sized both small enough to prevent tires from slipping through and large enough to pass a lower rim 17 , which is rotatably mounted on a vertically telescoping lower rim assembly 18 . The upper rim 20 is rotatably mounted on the upper part of the frame 11 through an upper rim spindle 21 . The upper rim 20 is opposite to the lower rim 17. During the test, the lower rim 17 is in the figure 1 In the extended position shown and in partial perspective view 2, the upper rim 20 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com