Dedicated repetitive defect detection in the web preparation process

A defect detection, web technology, applied in the inspection of textile materials, optical testing flaws/defects, measuring devices, etc., can solve problems such as uninspection, incorrect roll assumption diameter, etc., to achieve simple and more robust maintenance, simple and more Effect of Robust Preparation Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

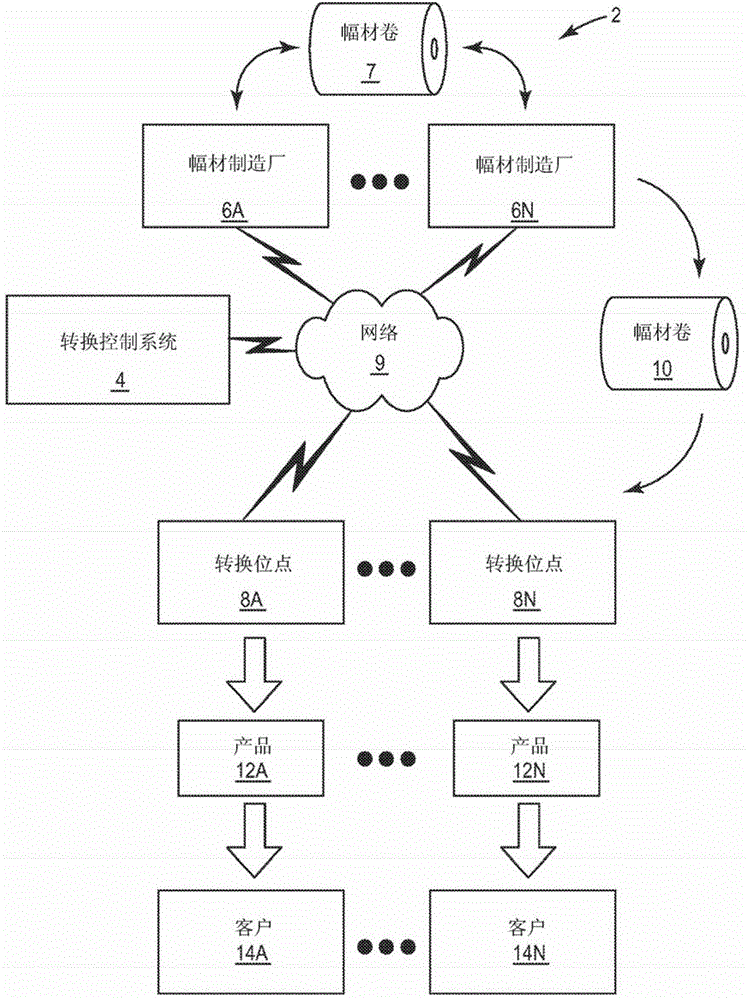

[0066] figure 1 is a block diagram showing a global network environment 2 in which a conversion control system 4 controls the conversion of webs. More specifically, web mills 6A-6M ("web mills 6") represent the production and delivery of web in the form of web rolls 7 between each other and the delivery of finished web rolls 10 to conversion sites Preparation sites for 8A-8N (switching site 8). The web manufacturing plants 6 may be geographically distributed, each of which may include one or more production lines. The conversion site 8 may be part of the same entity as the web manufacturing plant 6 . However, in some embodiments, the conversion site 8 is a customer of the finished web roll 10 . The conversion site 8 may purchase finished web rolls 10 from the web fabrication plant 6 and then convert the finished web rolls 10 into individual sheets assembled into products 12 according to grade level. That is, it is possible to select which sheet should be assembled into wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com