Assembly equipment of tank bottom cover

A technology for assembling equipment and bottom covers, which is applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of lower production efficiency, inability to adapt to automation, poor continuity, etc., and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content and structural features of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

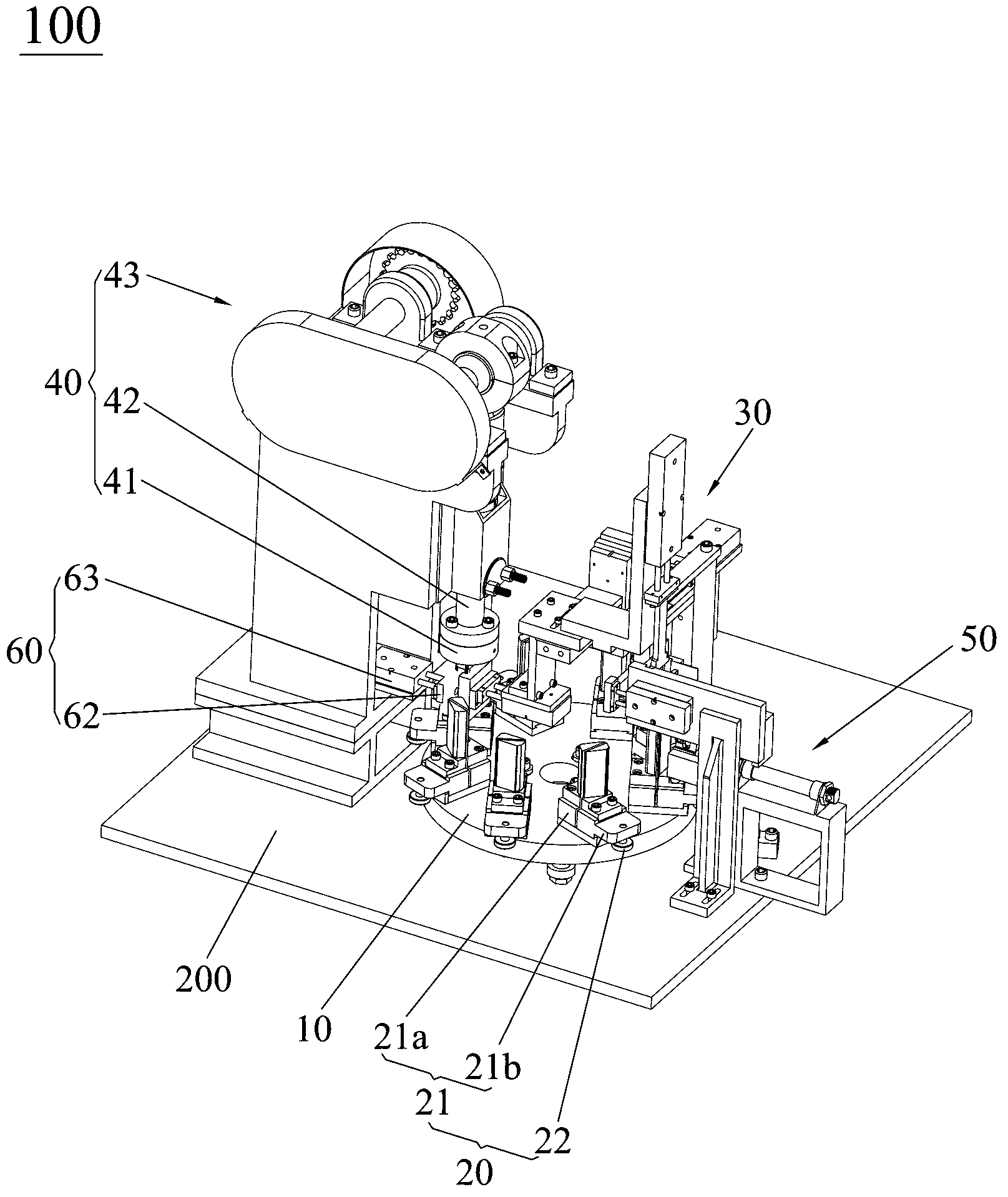

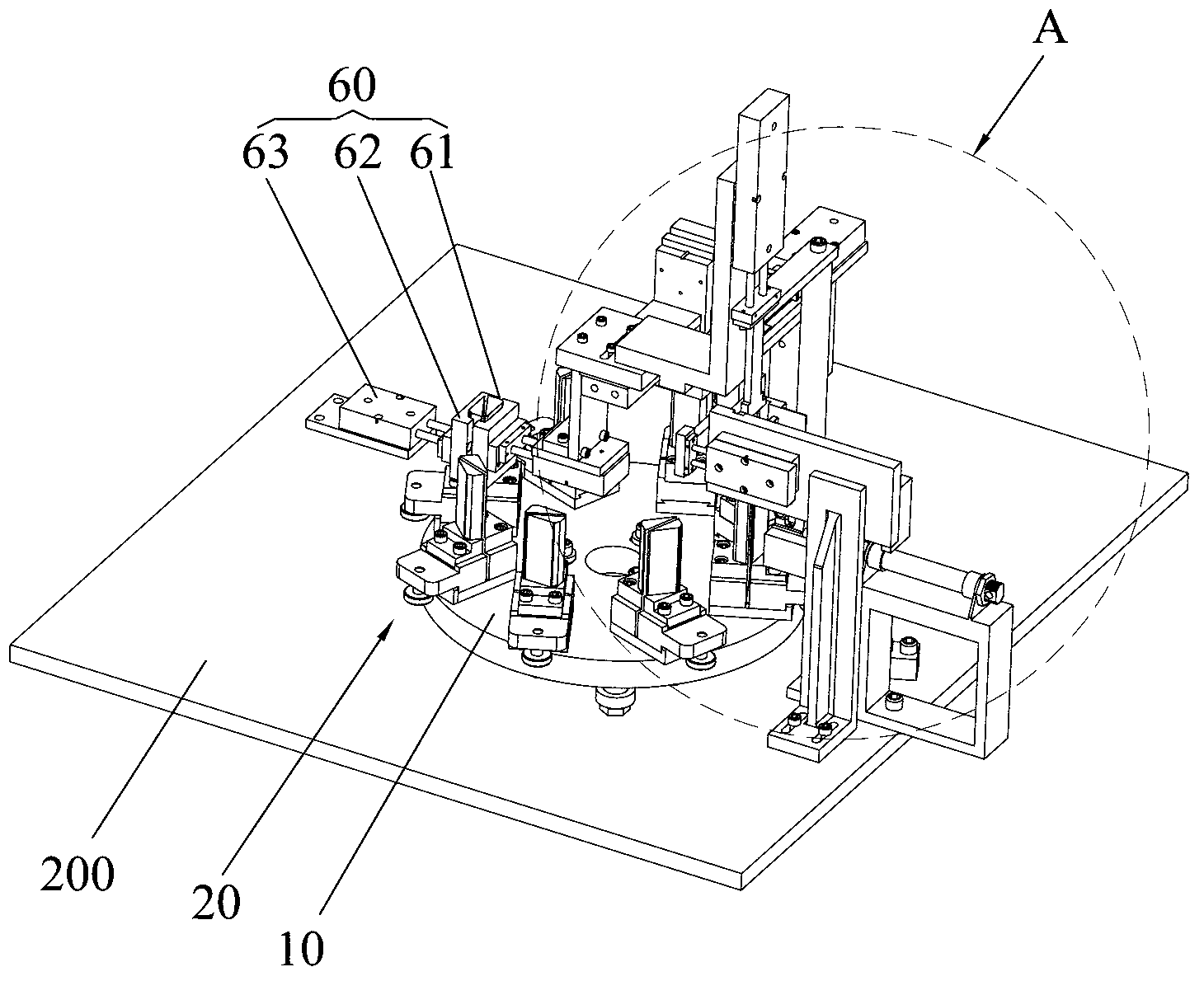

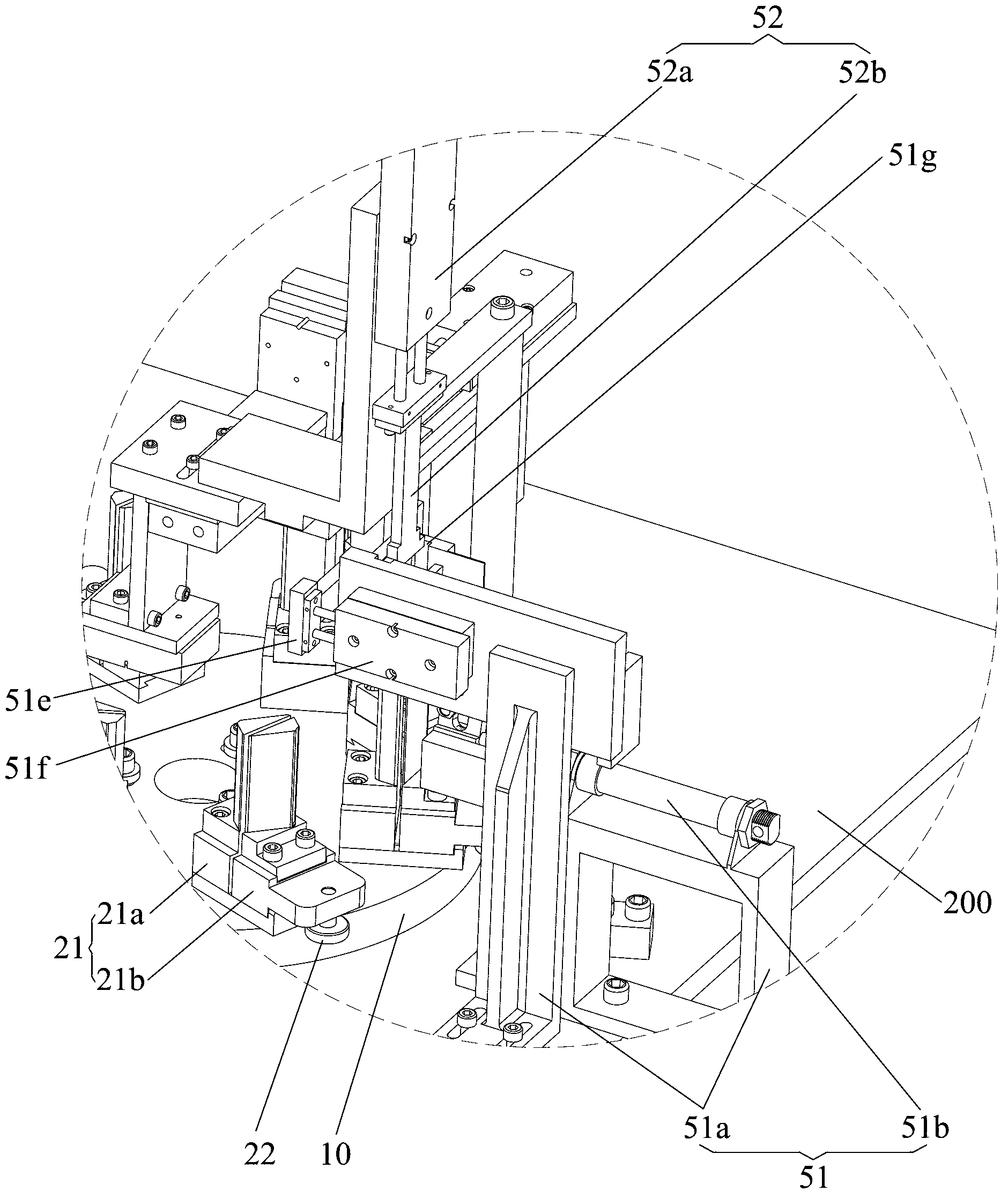

[0026] see Figure 1 to Figure 5 ,as well as Figure 8, the assembly equipment 100 of the bottom cover of the tank body of the present invention is arranged on the installation seat 200 and assembles the cylinder body 310 and the bottom cover 320 into a tank body 300 of an integral structure, wherein the assembly equipment 100 of the bottom cover of the tank body of the present invention includes a rotary table 10. Bottom cover loading mechanism 30 , stamping mechanism 40 and several clamping mechanisms 20 . The turntable 10 is rotatably arranged on the mounting base 200, and the clamping mechanism 20 can be three, four, five, six, seven or eight, etc., but these are all Those of ordinary skill in the art are well known according to actual needs, so the number of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com