Electric screw press

An electric screw and motor technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of high manufacturing cost and difficulty in manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

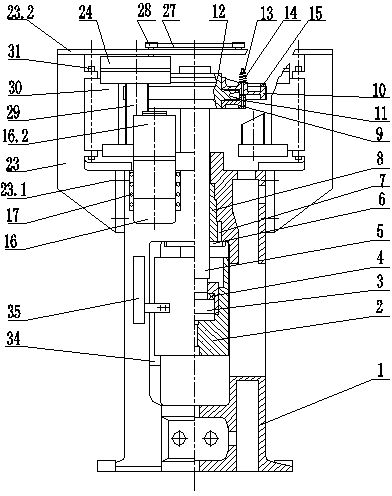

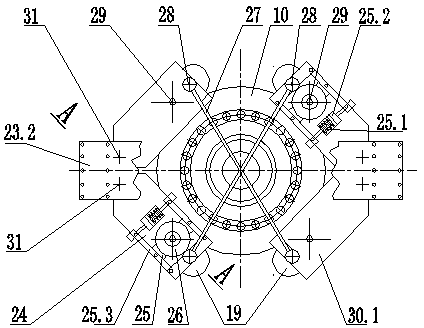

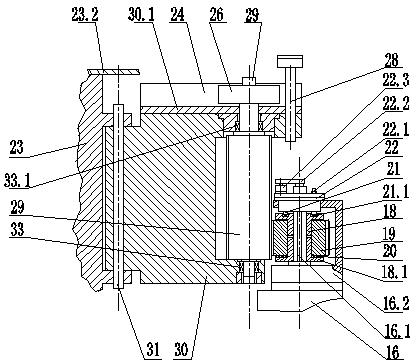

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] This embodiment provides an electric screw press, such as figure 1 and figure 2 Shown, comprise fuselage 1, motor 16 of even number, screw rod 5, slide block 2 and the inertial wheel that outer ring is gearwheel 10, four guide rails 34 are arranged on fuselage 1, slide block 2 can be made along fuselage guide rail 34 Reciprocating linear motion. The nut 8 is connected with the fuselage 1 as a whole through the flange 6 and the key 7, and the screw rod 5 and the nut 8 are threaded. The lower end of screw rod 5 is equipped with thrust bearing 3, and cooperates with slide block 2 through bearing 4. The screw rod 5 drives the slider 2 to move linearly by forming a helical pair with the nut 8 . The inertia wheel is composed of disk 9, gear wheel 10, friction block 11, wheel hub 12, bolt 13, spring 14 and positioning ring 15, and the inertia wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com