On-line Adjustable Gas Generator Using Jet Collision Combustion

A technology of gas generator and combustion method, which is applied in the direction of machine/engine, jet propulsion device, rocket engine device, etc. It can solve the problems of difficult to simulate the airflow environment changes of aircraft, long combustion chamber length by diffusion combustion, and increase the cooling area of combustion chamber, etc. problems, to achieve good combustion efficiency, good flame stability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

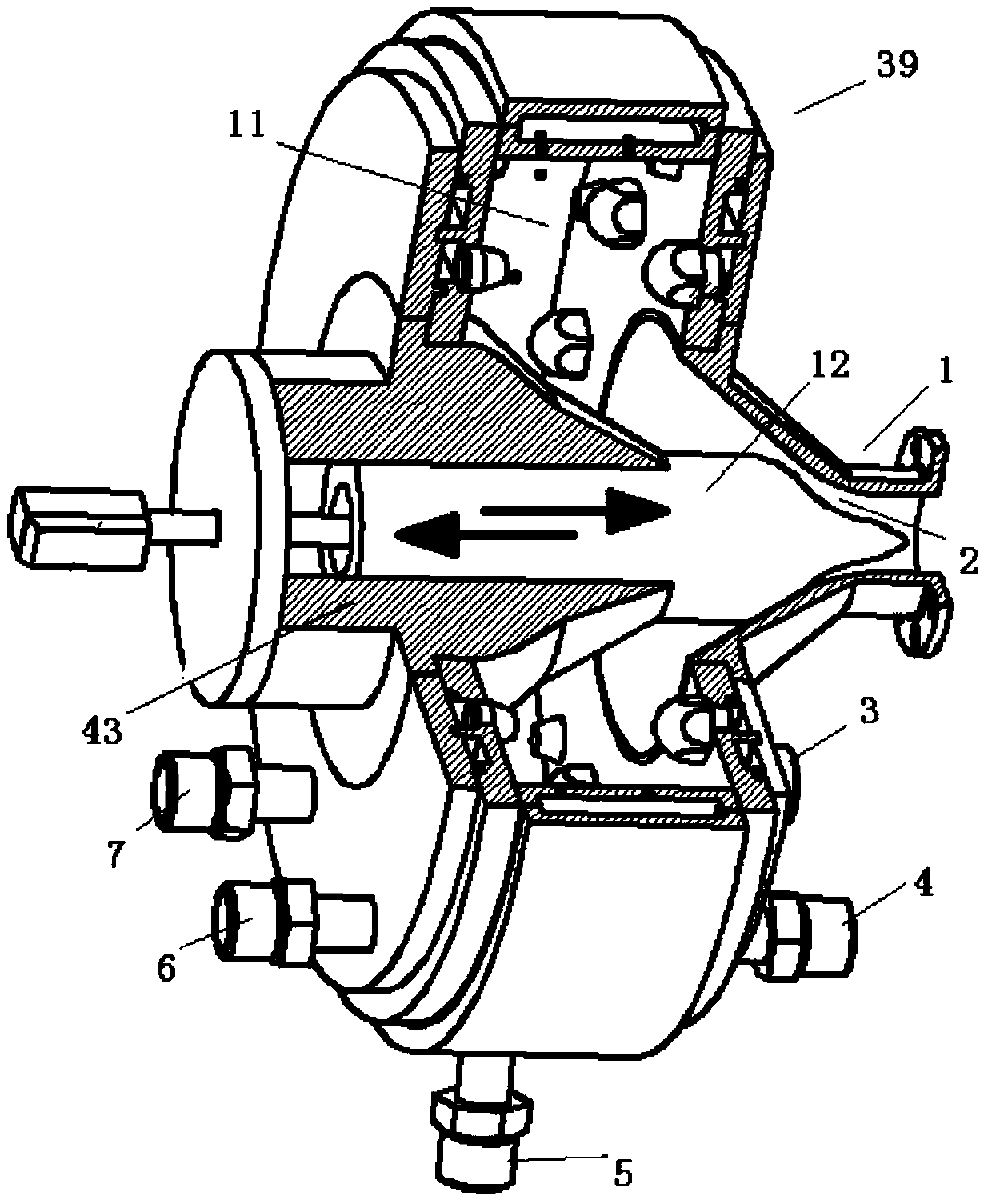

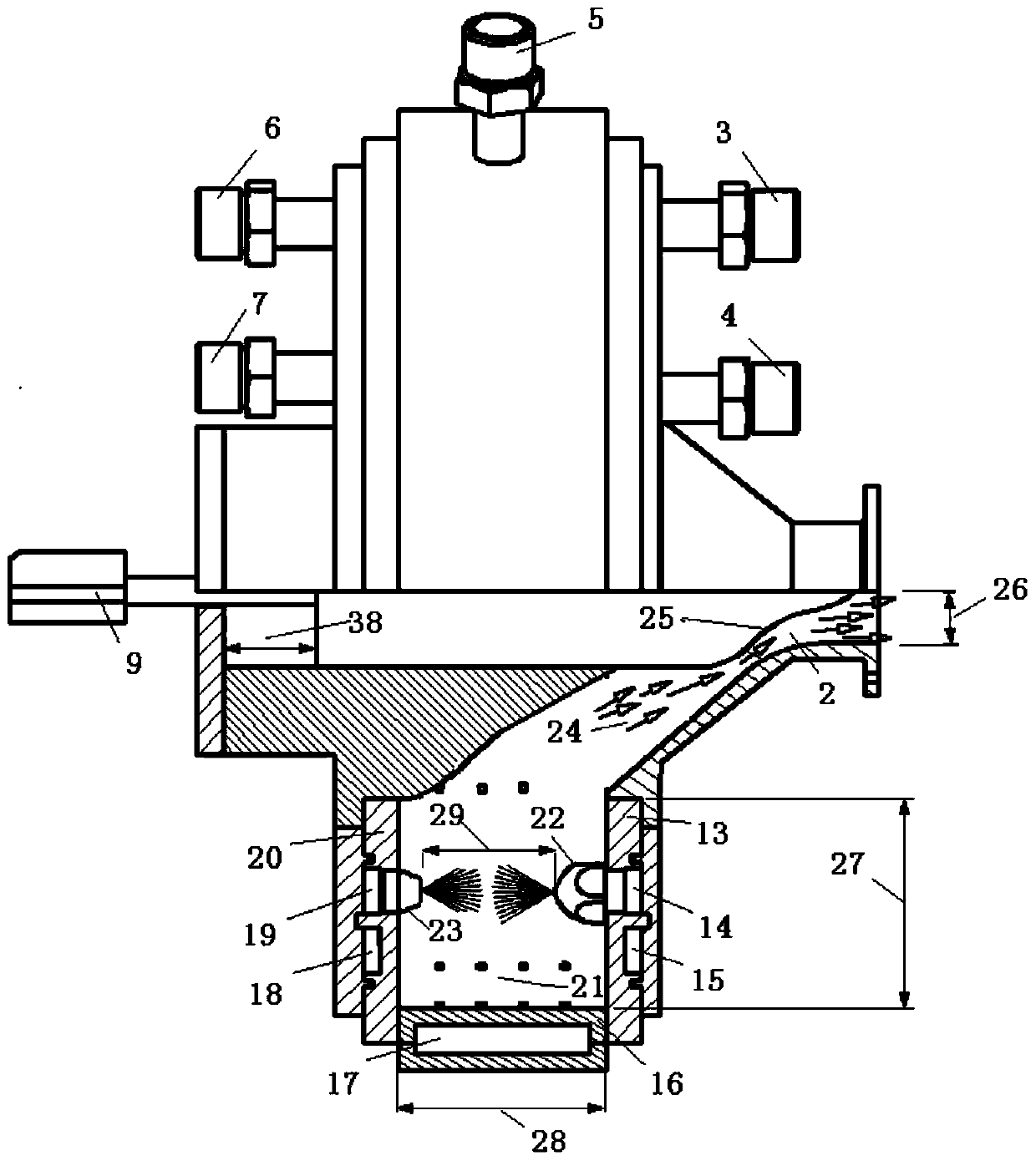

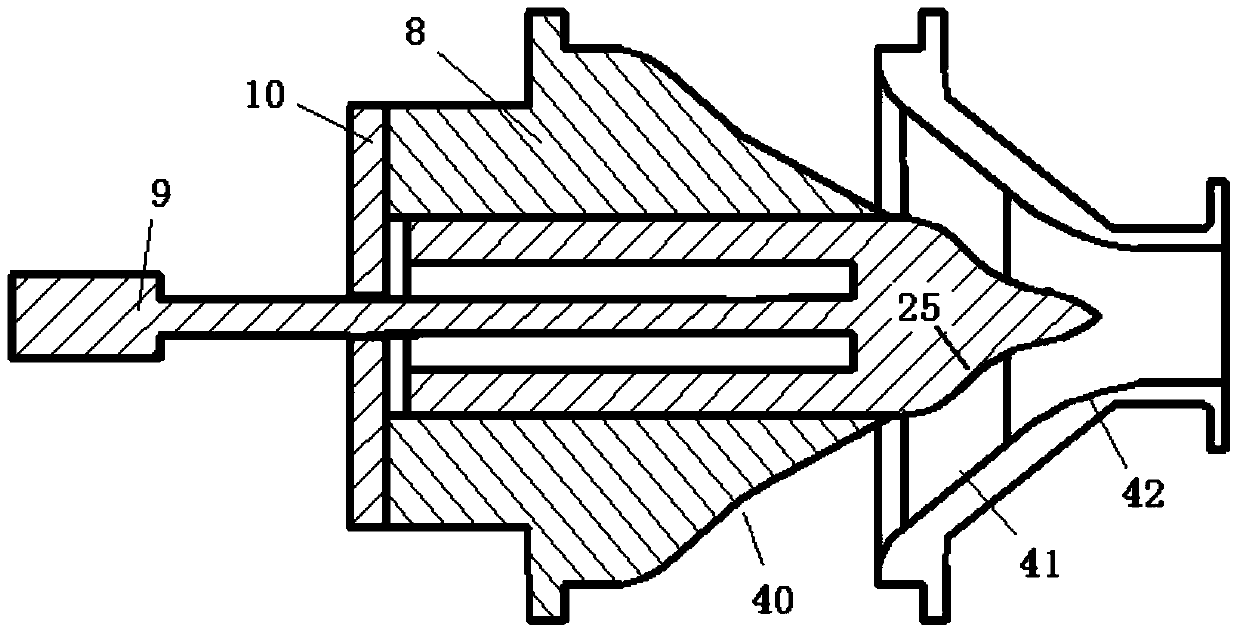

[0022] Such as figure 1 , figure 2 As shown, in the annular groove combustion chamber 11 formed by the combination of the front injection panel 20, the rear injection panel 13, and the body cooling panel, the umbrella-shaped airflow ejected from the oxidizer nozzle 23 is in phase with the spray spray from the fuel nozzle 22. collide, carry out mixed combustion, and form a stationary aerodynamic vortex structure in the combustion chamber 11. The length dimension 28 of the combustion chamber is determined according to the nozzle interaction distance 39 determined by the jet penetration length of the nozzle, so as to ensure the effective organization of the collision jet spray combustion. The radial size 27 of the combustion chamber is determined according to the flow power of the combustion chamber and the installation conditions.

[0023] Cooling liquid is injected into the body cooling injection panel 16 to perform liquid film regenerative cooling on the body, and the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com