Fat-die plunger type biomass solidifying forming machine

A plunger type, biomass technology, applied in material forming presses, biofuels, punching machines, etc., can solve the problems of high energy consumption, simple structure, inability to adapt to the forming of various raw materials, etc., to reduce energy consumption, The effect of enhancing usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

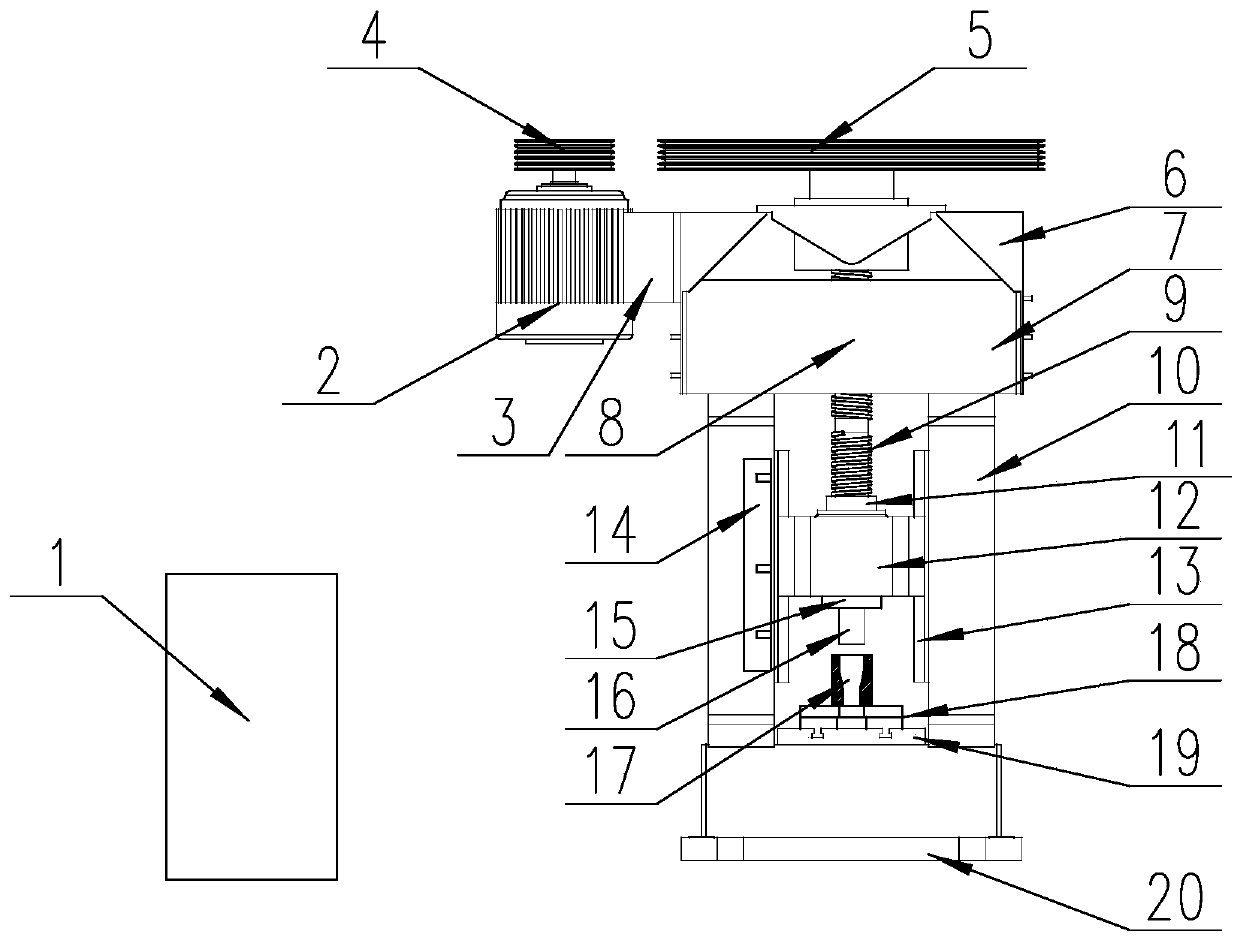

[0027] like figure 1 , figure 2 As shown, a flat die plunger type biomass solidification molding machine includes a working platform 19, the working platform 19 is arranged on the upper part of the base 20, and the base 20 is fixed on the ground by four anchor bolts. The top of the working platform 19 is connected with two symmetrically arranged uprights 10, the top of the uprights 10 is equipped with a crossbeam 7, the top of the crossbeam 7 is connected with a fixed bracket 6, the fixed bracket 6 spans the top of the crossbeam 7, and one end of the fixed bracket 6 is connected to the motor Frame 3, the other end is used for fixing and installing the brake assembly. Motor frame 3 is equipped with motor 2. The motor output shaft is connected with the first belt pulley 4, and the first belt pulley 4 is connected with the flywheel 5 through a transmission belt, and the transmission belt is selected for use as a belt. The bottom of the flywheel 5 is connected to a lead screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com