Valve plate assembly

A valve plate and component technology, applied in the field of valve plate components, can solve the problems of poor wear resistance and inconvenient replacement of guide rails, and achieve the effects of improved wear resistance, good verticality, and convenient replacement and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

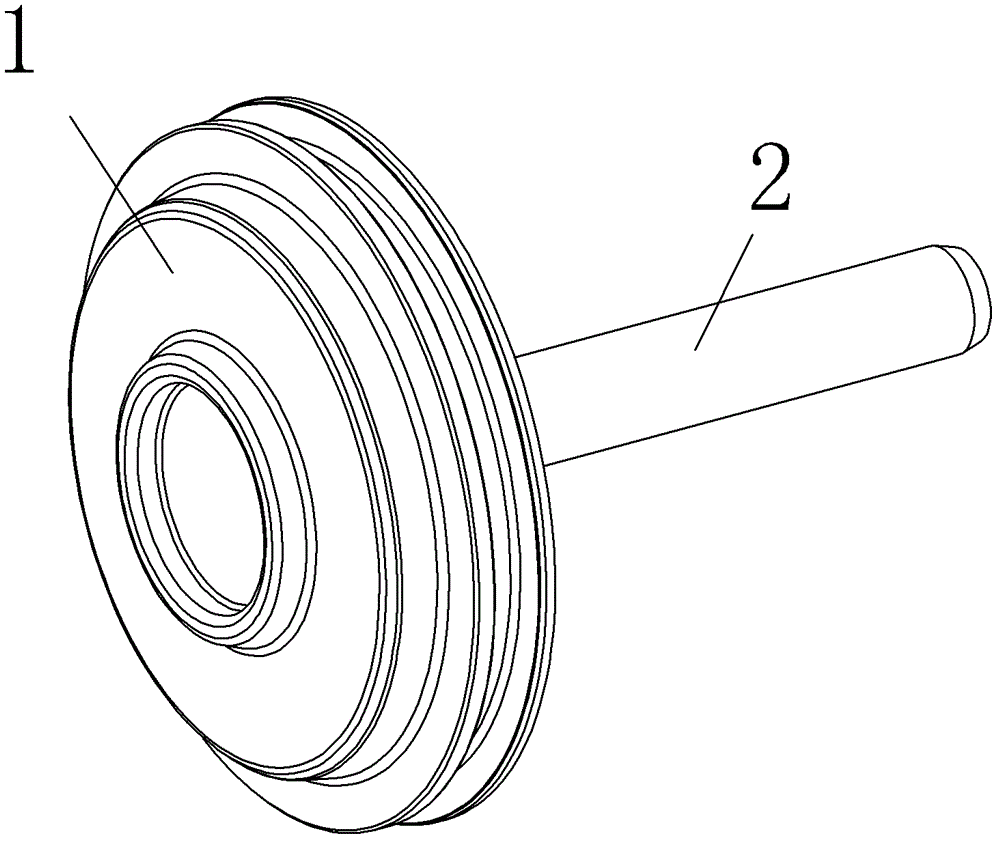

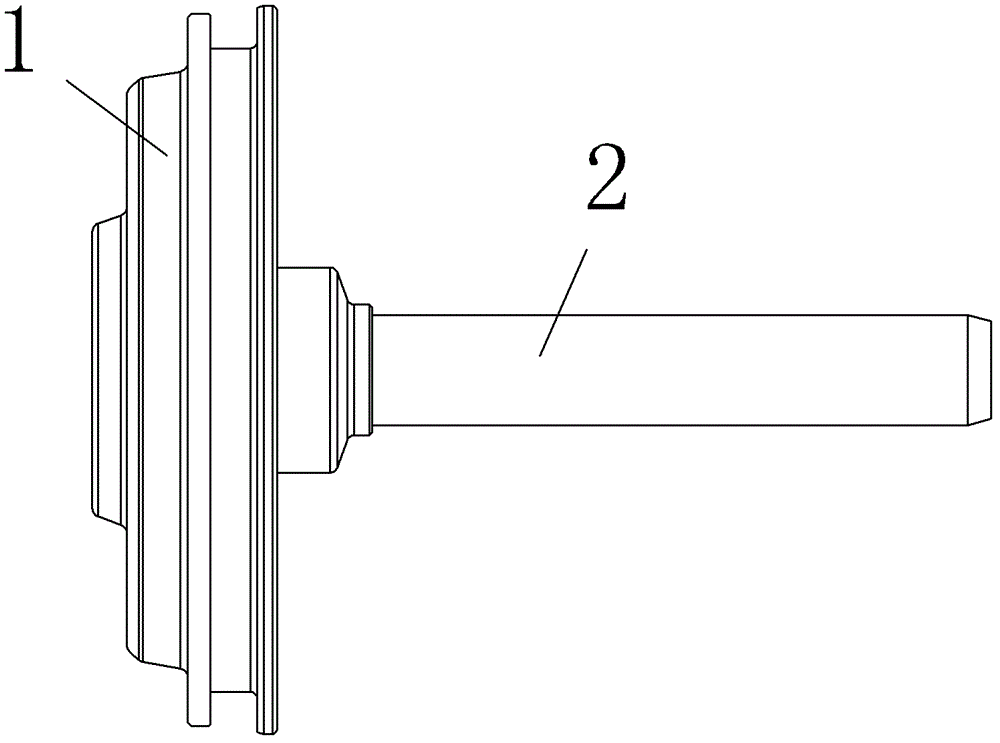

[0015] Such as Figure 1 to Figure 4 As shown, the valve plate 1 and the valve plate guide rail 2 are movably connected in a detachable manner. For example, threaded connection can be used. Specifically, an internal threaded hole for screw connection with the valve plate guide rail 2 can be drilled at the end of the valve plate guide rail 2, and an external thread corresponding to the internal threaded hole is processed on the peripheral surface of the valve plate guide rail.

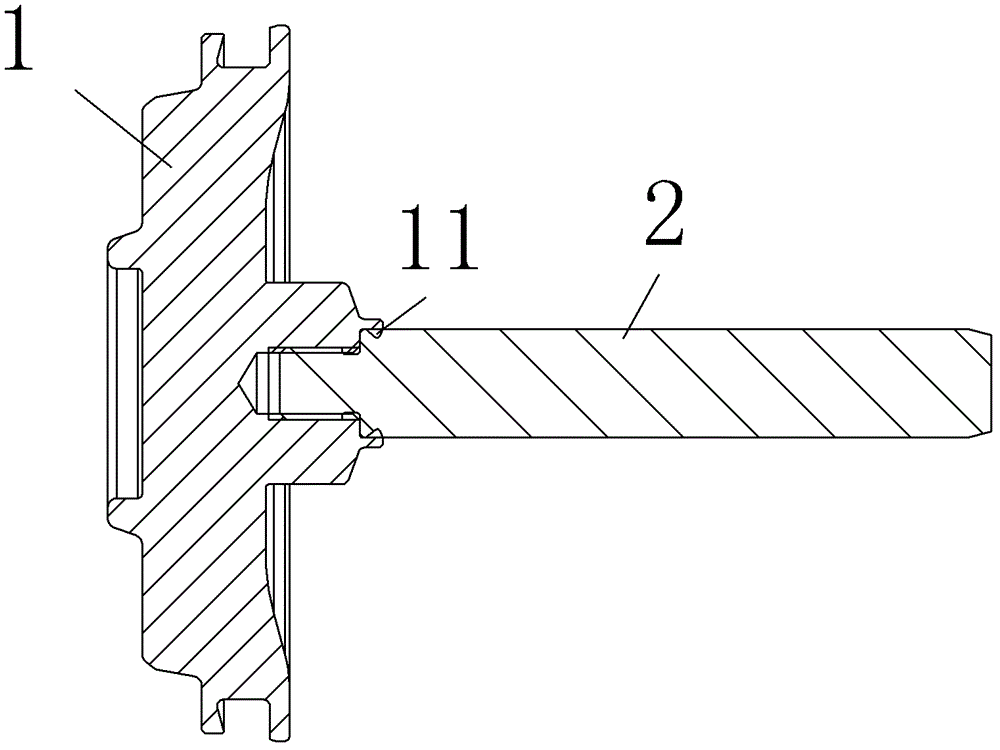

[0016] In order to ensure the firmness of the connection between the valve plate 1 and the valve plate guide rail 2, a ring of inner rim 11 protruding inward is provided at the port of the internal threaded hole connecting the valve plate guide rail 2 and the valve plate 1. Correspondingly, a corresponding groove is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com