Lifting drive mechanism of travelling crane

A technology of transmission mechanism and hoisting rope, applied in the direction of walking bridge cranes, cranes, transmission devices, etc., can solve the problems of high maintenance cost, large investment and complex structure, so as to reduce the initial investment, reduce the later use cost, extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

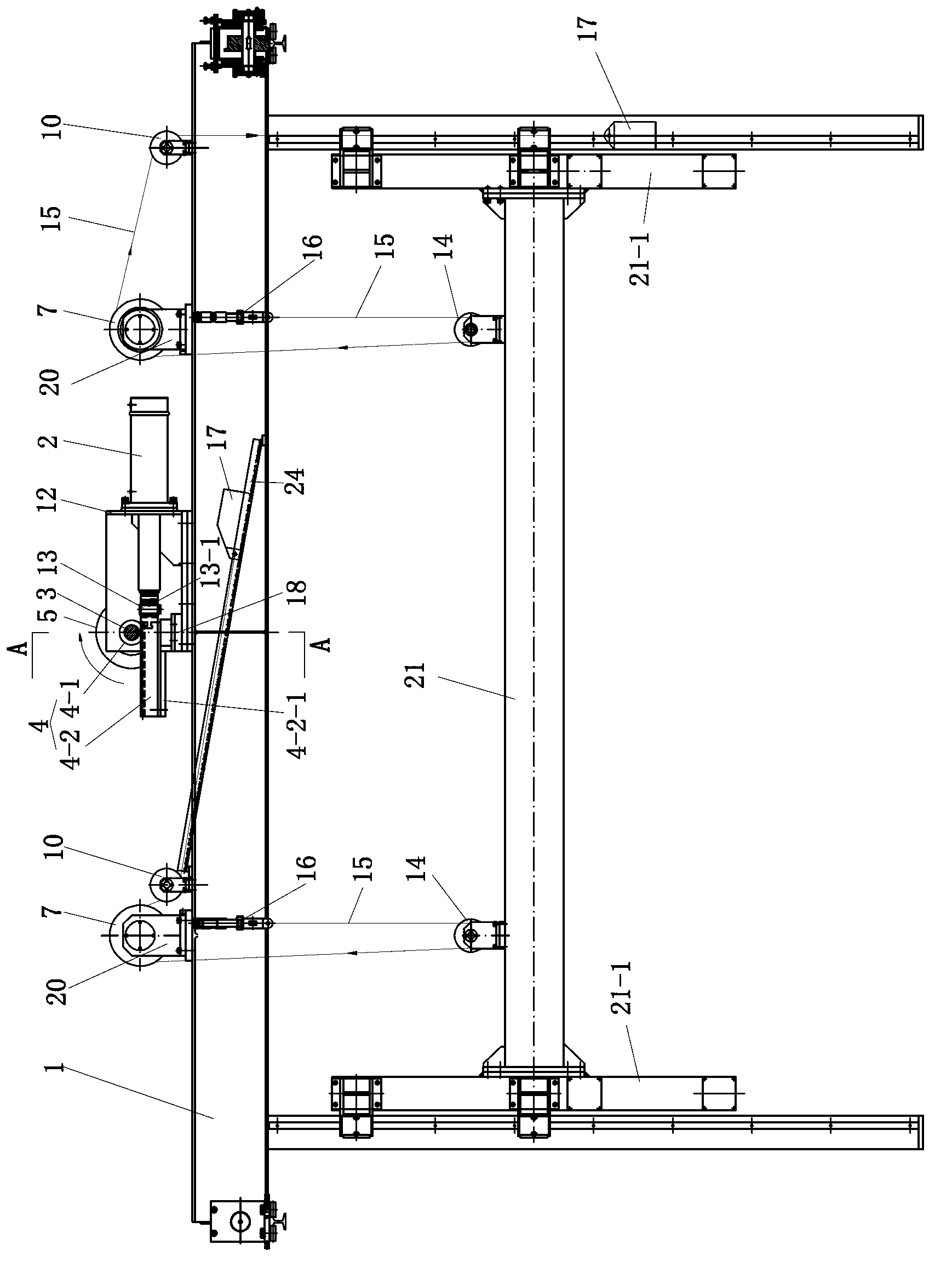

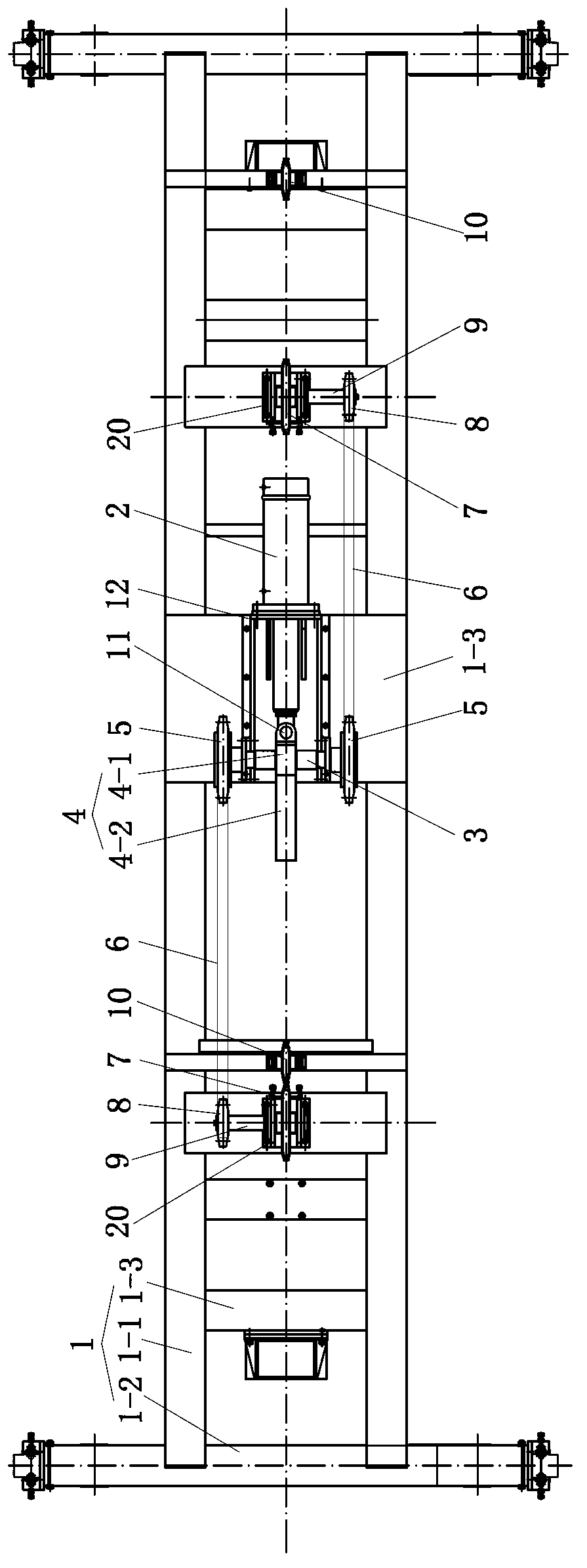

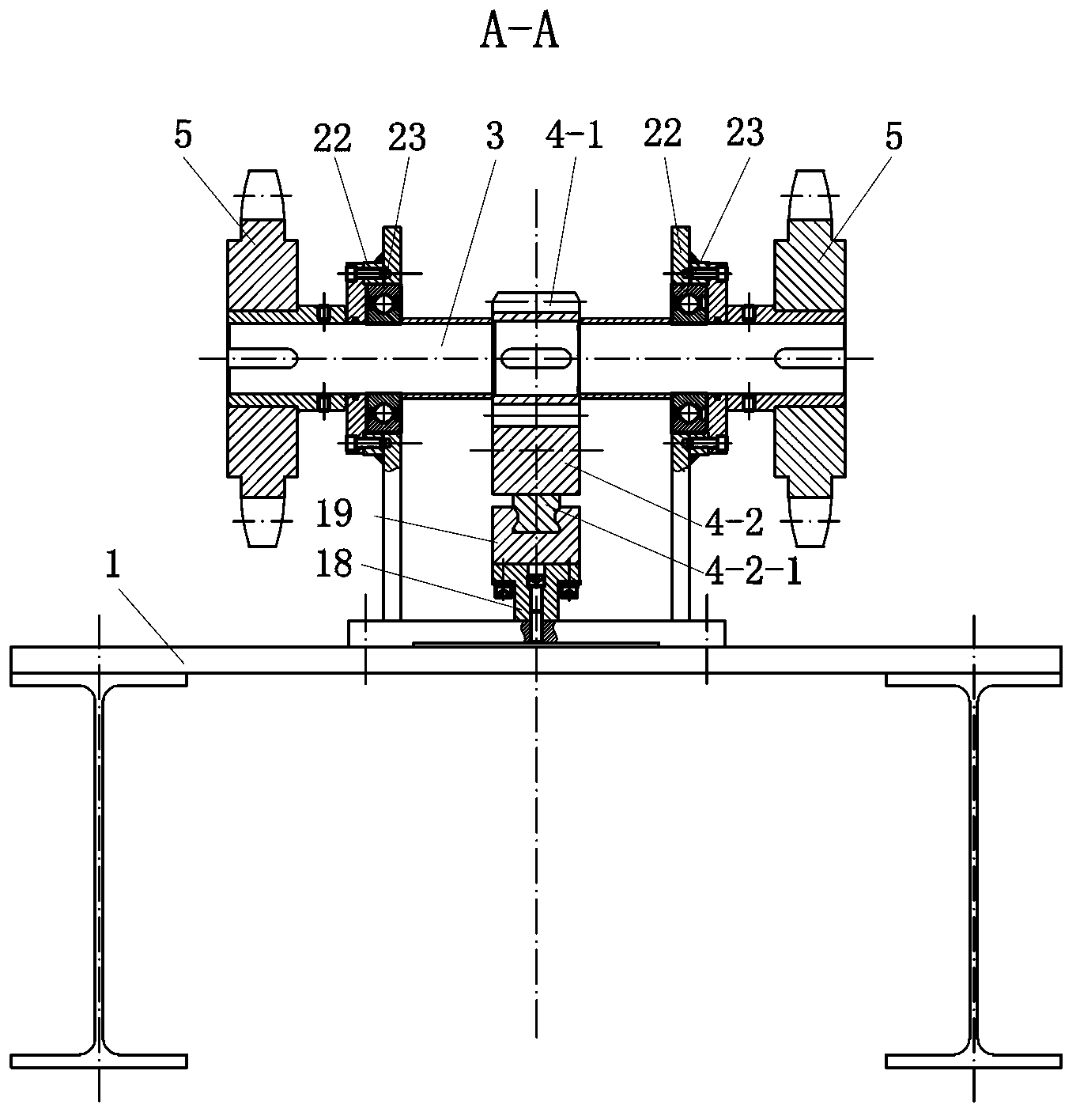

[0018] Embodiment 1 shown in the accompanying drawing comprises the hydraulic oil cylinder 2 that is arranged on the top surface of the main beam 1 and the lifting beam 21 below the main beam 1. In order to make the lifting beam 21 rise and fall stably, both sides of the lifting beam 21 are respectively fixed. There is a mobile support 21-1, and the mobile support 21-1 slides along the driving column. The main crane beam 1 has a frame composed of two beams 1-1 and beams 1-2 at both ends, and a support plate 1-3 or a support beam 1-3 is fixed on the frame corresponding to the mounting parts.

[0019] Drive shaft 3, driven shaft 9 on the left and right sides of drive shaft 3, and a rack and pinion pair 4 are arranged on the top surface of the main beam 1 for driving, and the rack 4-2 of the rack and pinion pair 4 is controlled by the hydraulic cylinder 2 Driven to slip, the gear 4-1 is installed on the drive shaft 3 to drive the drive shaft 3 to rotate. On the drive shaft 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com