Water-based high temperature plain colored paint capable of being used for wet-on-wet middle-coating-free system and preparation method thereof

A wet-on-wet, system technology, used in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc., can solve the problem of poor weather resistance, stone chip resistance, and poor stone chip resistance and weather resistance. and other problems, to achieve excellent physical and mechanical properties, reduce labor and operating costs, and improve cross-linking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

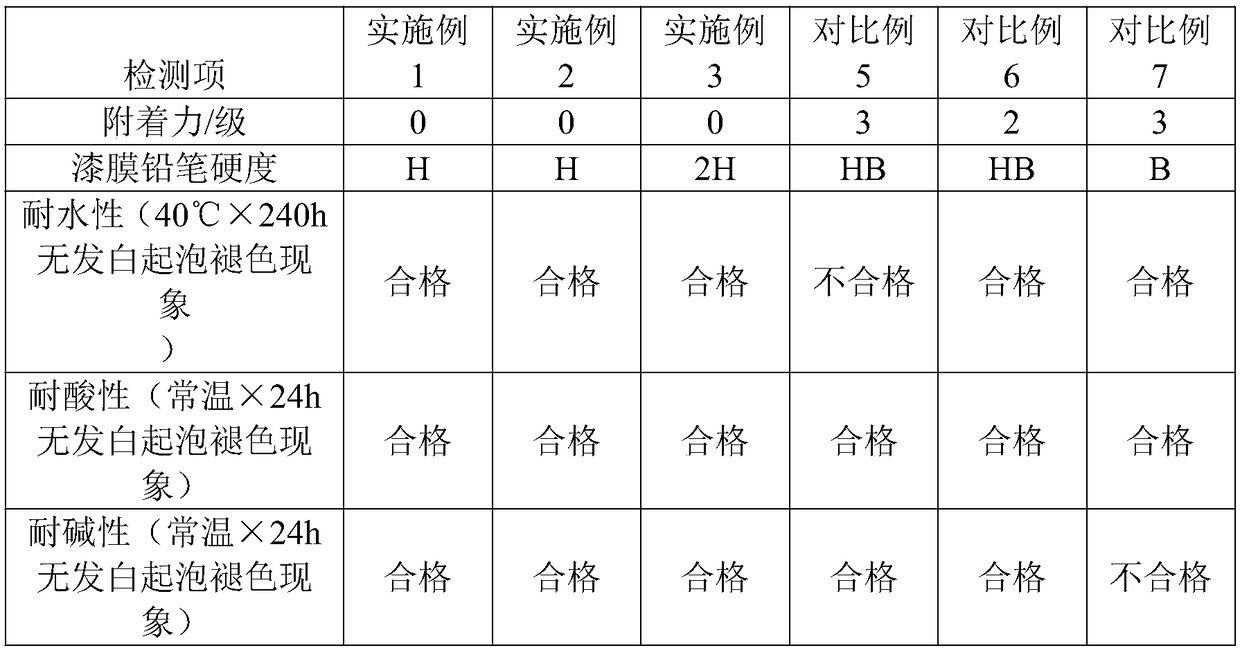

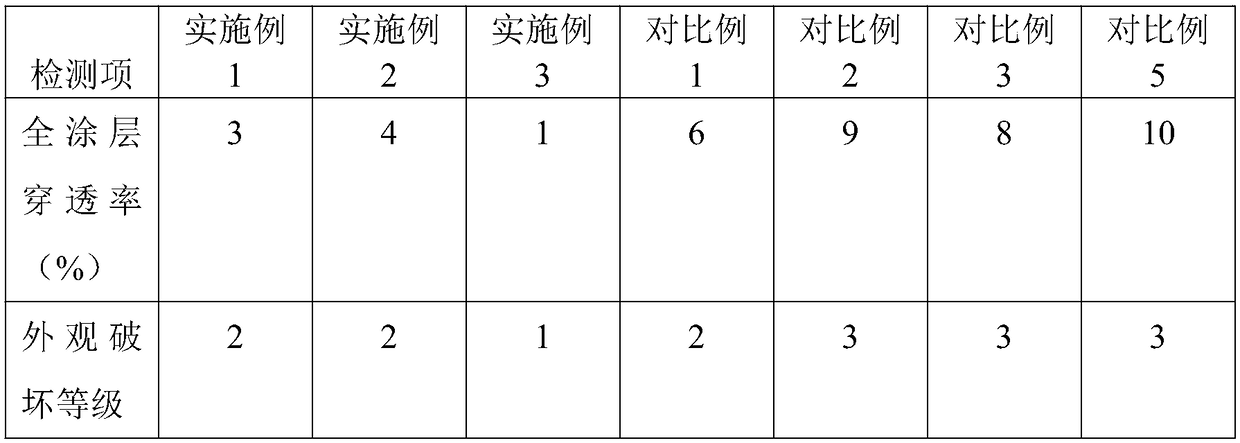

Examples

Embodiment 1

[0039] Embodiment 1, a kind of water-based high-temperature plain paint that can be used for wet-on-wet free intermediate coating system

[0040] The water-based high-temperature plain paint that can be used in the wet-on-wet primer-free system includes A component and B component, wherein the A component is composed of the following components and their weight percentages: water-based acrylic polyol dispersion 14%, water-based polyurethane dispersion 20%, ultra-fine talc powder 3%, ultra-fine barium sulfate 10%, aluminum tripolyphosphate 5%, titanium dioxide 15%, carbon black 0.5%, water-based dispersant 5%, methyl etherification Amino resin 3%, pure water 24.5%; The water-based dispersant is made up of polyvinylpyrrolidone, sodium lignosulfonate and Digao Dispers 755W dispersant in a weight ratio of 2:9:22;

[0041] The B component is composed of the following components and their weight percentages: 10% of water-based acrylic polyol dispersion, 20% of water-based polyuretha...

Embodiment 2

[0055] Embodiment 2, a kind of water-based high-temperature plain paint that can be used for wet-on-wet free intermediate coating system

[0056] The water-based high-temperature plain paint that can be used in the wet-on-wet primer-free system includes A component and B component, wherein the A component is composed of the following components and their weight percentages: water-based acrylic polyol dispersion 20%, water-based polyurethane dispersion 10%, ultra-fine talc powder 10%, ultra-fine barium sulfate 3%, aluminum tripolyphosphate 4.8%, titanium dioxide 25%, carbon black 0.2%, water-based dispersant 2%, methyl etherification Amino resin 5%, pure water 20%; The water-based dispersant is made up of polyvinylpyrrolidone, sodium lignosulfonate and Digao Dispers 755W dispersant in a weight ratio of 5:7:18;

[0057] The B component is composed of the following components and their weight percentages: 20% of water-based acrylic polyol dispersion, 12% of water-based polyuretha...

Embodiment 3

[0069] Embodiment 3, a kind of water-based high-temperature plain paint that can be used for wet-on-wet free intermediate coating system

[0070] The water-based high-temperature plain paint that can be used in the wet-on-wet primer-free system includes A component and B component, wherein the A component is composed of the following components and their weight percentages: water-based acrylic polyol dispersion 20%, water-based polyurethane dispersion 15%, ultra-fine talc powder 5%, ultra-fine barium sulfate 4%, aluminum tripolyphosphate 3%, titanium dioxide 22%, carbon black 0.2%, water-based dispersant 2%, methyl etherification Amino resin 4%, pure water 24.8%; The water-based dispersant is made up of polyvinylpyrrolidone, sodium lignosulfonate and Digao Dispers 755W dispersant in a weight ratio of 3:8:20;

[0071] The B component is composed of the following components and their weight percentages: 15% of water-based acrylic polyol dispersion, 20% of water-based polyurethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com