Method utilizing petroleum coke powder to prepare petroleum type coke, product and equipment thereof

A technology of petroleum coke powder and petroleum, which is applied in the field of energy utilization, can solve the problems of poor cold strength and thermal stability of petroleum coke, poor reactivity of petroleum coke, and large combustion smoke of petroleum coke, so as to achieve low pollution in the production and use of finished products, High mechanical strength and low ash melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 Preparation of Petroleum Coke by Using Petroleum Coke Powder

[0089] Include the following steps:

[0090] (1) Low-temperature drying treatment of raw materials of petroleum coke powder:

[0091] Using a low-temperature drying device, the temperature is controlled at 200°C, and the petroleum coke powder raw material (with a sulfur content of 3%) is dried to obtain the petroleum coke powder processing raw material;

[0092] (2) After mixing the low-sulfur coal powder with a sulfur content of 0.38% and the petroleum coke powder treatment raw material obtained in step (1) according to the weight ratio of 4:6, mix according to the mixture of petroleum coke powder and coal powder: binder : The mixture of calcium carbonate (desulfurizer) and calcium-based bentonite (stabilizer) = 100:2:3 by weight, add binder, desulfurizer, and minerals used to increase the thermal stability of petroleum coke products into the mixture Calcium-based bentonite, uniformly mixed, whe...

Embodiment 2

[0096] Example 2 Preparation of Petroleum Coke by Using Petroleum Coke Powder

[0097] Include the following steps:

[0098] (1) Low-temperature drying treatment of raw materials of petroleum coke powder:

[0099] Using a low-temperature drying device, the temperature is controlled at 250°C, and the petroleum coke powder raw material (with a sulfur content of 5%) is dried to obtain the petroleum coke powder processing raw material;

[0100] (2) After mixing the low-sulfur coal powder with a sulfur content of 0.38% and the petroleum coke powder treatment raw material obtained in step (1) in a weight ratio of 3:5, the mixture of petroleum coke powder and coal powder: bonding Agent: a mixture of calcium carbonate (sulfur removing agent) and calcium-based bentonite (stabilizer) = 100:2:3 by weight. Add binder, calcium carbonate (sulfur removing agent) Calcium-based bentonite with thermal stability of the product, mixed evenly, wherein the weight ratio of calcium carbonate to cal...

Embodiment 3

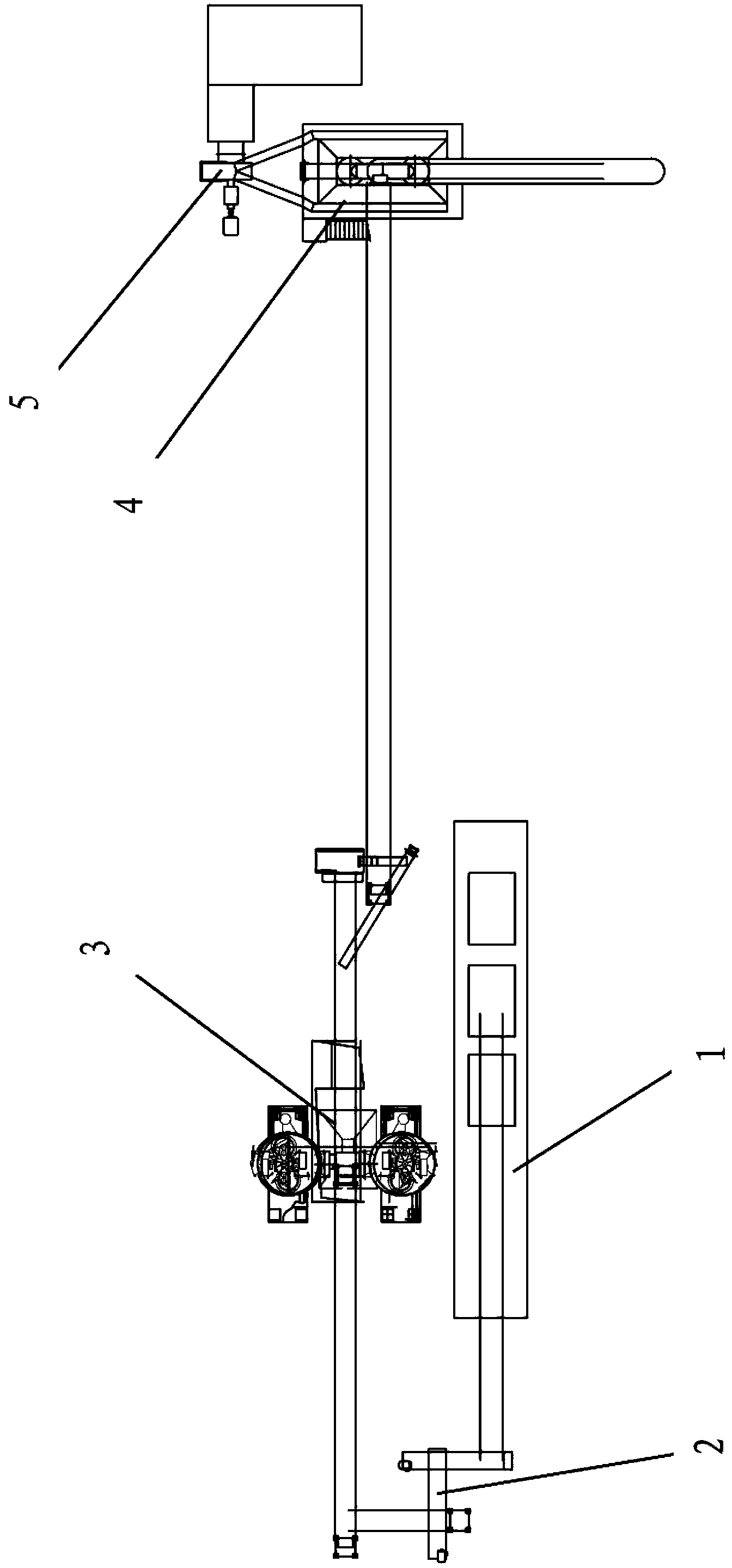

[0104] Example 3 Utilize the method of the present invention in combination with the equipment of the present invention to prepare petroleum coke

[0105] Such as figure 1 Shown is the plan layout of the equipment for preparing petroleum coke provided by the invention, which includes a quantitative feeding device 1, a stirring device 2, a wheel mill 3, a molding machine 4 and a drying furnace connected in sequence 5, of which:

[0106] The dosing device 1 is connected to the stirring device 2 through a belt, and is used to provide raw materials (that is, a mixture of coal powder and petroleum coke powder) to the stirring device 2;

[0107] The stirring device 2 is provided with an additive feeding port (not shown), which is used to put binder, desulfurizer and other additives (such as: calcium-based bentonite) into the raw materials, and mix them evenly, and then put The mixed raw materials are sent to the wheel mill 3 by a belt; the stirring device 2 preferably adopts a bia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com