Micro-reactor and micro-reactor system, and method for producing low-carbon olefin from petroleum hydrocarbon

A technology of micro-reactors and low-carbon olefins, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, petroleum industry, etc., can solve problems such as uneven distribution of fluids, pressure drop differences in filled catalysts, etc., and achieve savings The effect of initial investment, reduced operating costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

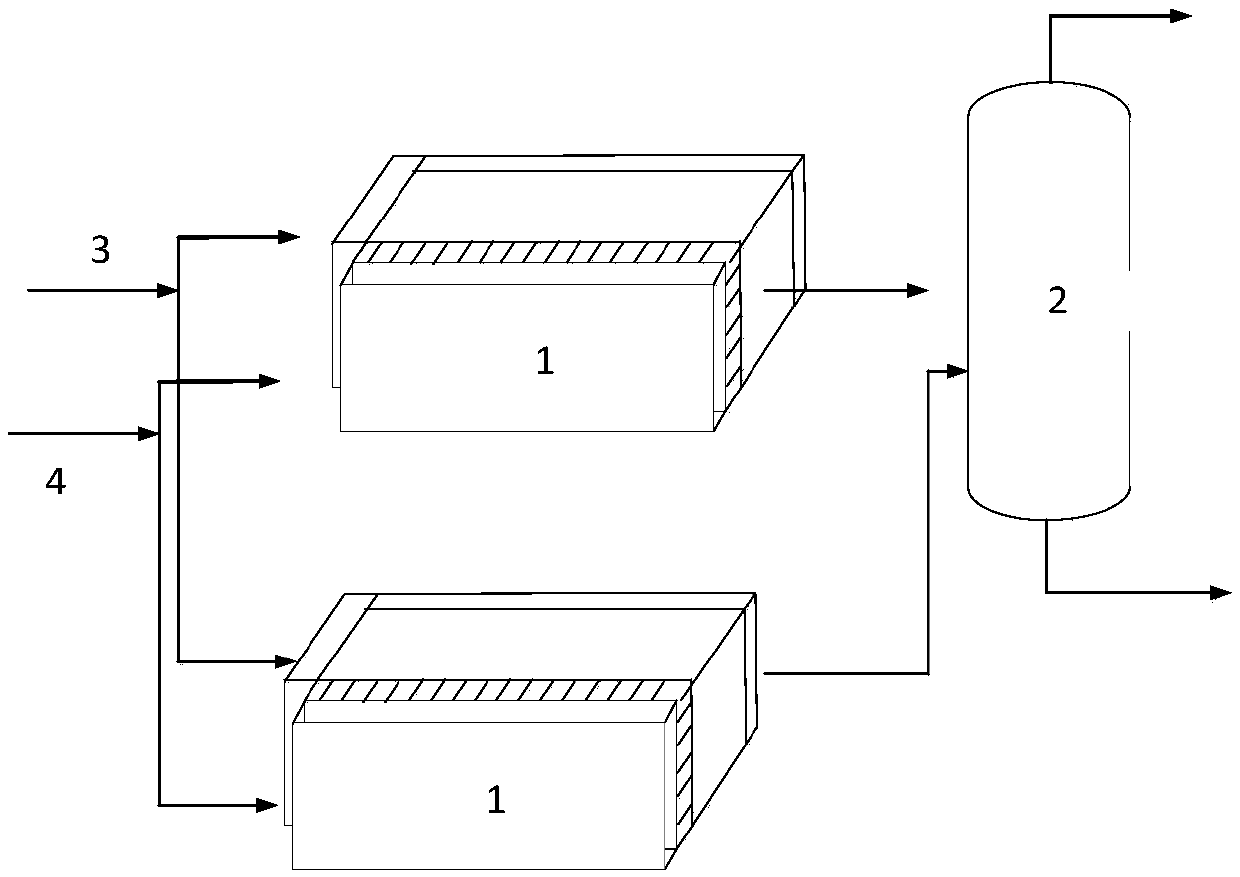

[0066] The reaction condition of embodiment 1 is identical with comparative example 1. The difference with the comparative ratio is that a microreactor device is used to carry out the catalytic cracking reaction. After the reaction in the microreactor is finished, stop feeding the reaction raw materials, and switch to air to regenerate the catalyst. After regeneration, the catalytic cracking reaction is recycled.

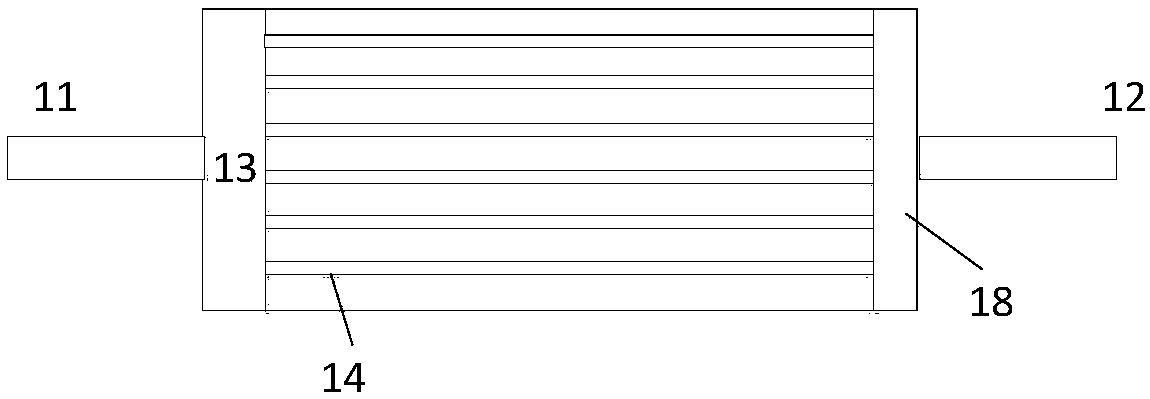

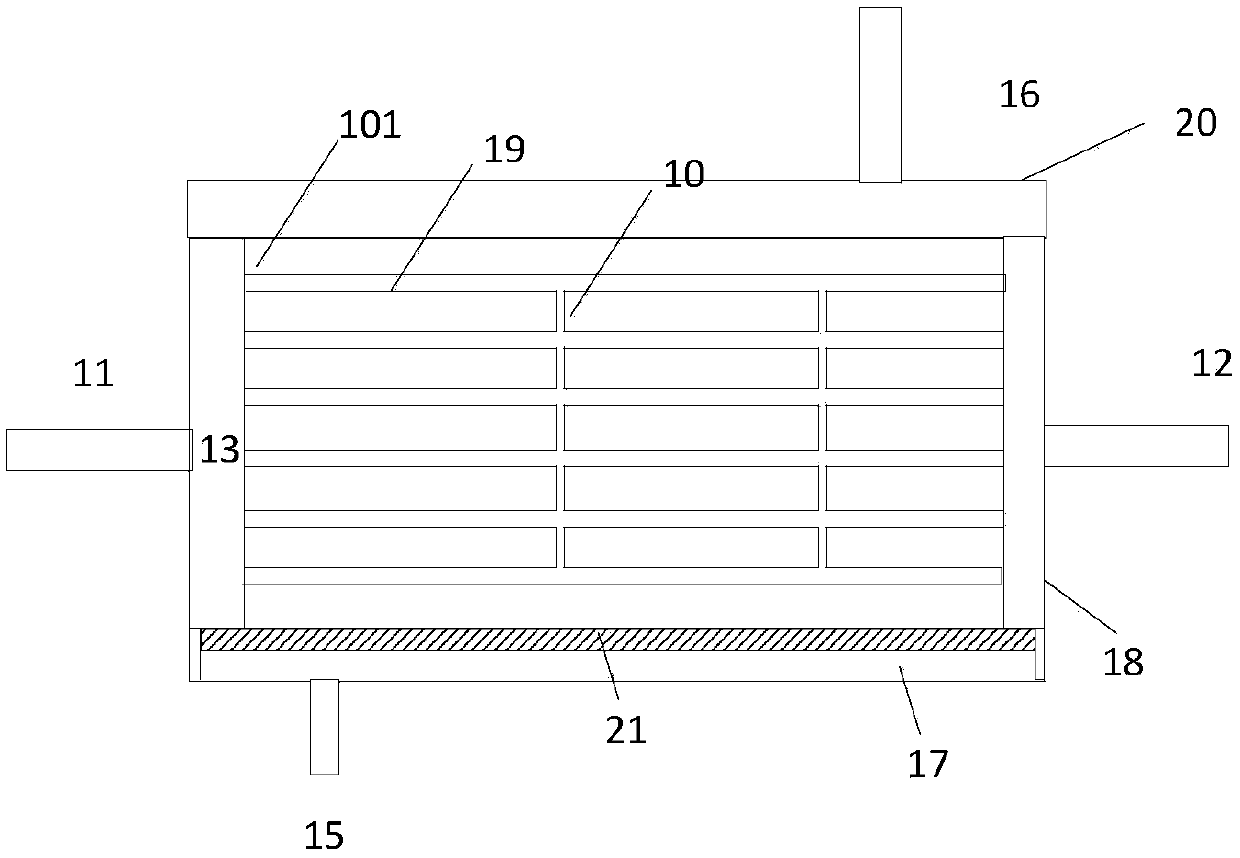

[0067] Use as attached figure 2 The microreactor shown has one reaction layer, including four microreaction channels. The top and bottom of the reaction layer are adjacent to the heat exchange layer, the inside of the heat exchange layer is a hollow cuboid, and the height of the heat exchange space is 5 mm. Each micro-reaction channel has the same cross-sectional area, and the cross-section of the micro-channel is rectangular. Adjacent micro-reaction channels communicate with each other through branch pipes, the branch pipes are located at the center of the mic...

Embodiment 2

[0071] In embodiment 2, the same aging catalyst A as in embodiment 1 is adopted, and the reaction conditions include: the temperature is 625° C., the reactor gauge pressure is 0 MPa, and the reaction space velocity is 8 h -1 .

[0072] The adopted microreactor has 3 reaction layers, each layer includes 6 micro reaction channels. Both sides of the reaction layer are adjacent to the heat exchange layer, that is, there are 4 hollow heat exchange layers in total, and the height of the heat exchange space is 8mm. Each micro-reaction channel has the same cross-sectional area, the length of the cross-section is 12mm, and the width is 1.5mm, and the cross-section of the micro-channel is rectangular. The microchannel is 1500mm long. Adjacent micro-reaction channels communicate with each other through branch pipes, the distance between adjacent branch pipes is 750 mm, and the branch pipes have a circular cross-section with a cross-sectional radius of 0.25 mm.

[0073] Table 1.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com