Rotary accommodating platform for hydraulic support for fully mechanized mining for coal mine

A technology for coal mines and platforms, which is applied to the field of rotary placement devices for fully mechanized coal mines, can solve the problems of low work efficiency, labor-intensive and time-consuming installation and retraction of hydraulic supports, and achieve the effects of reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

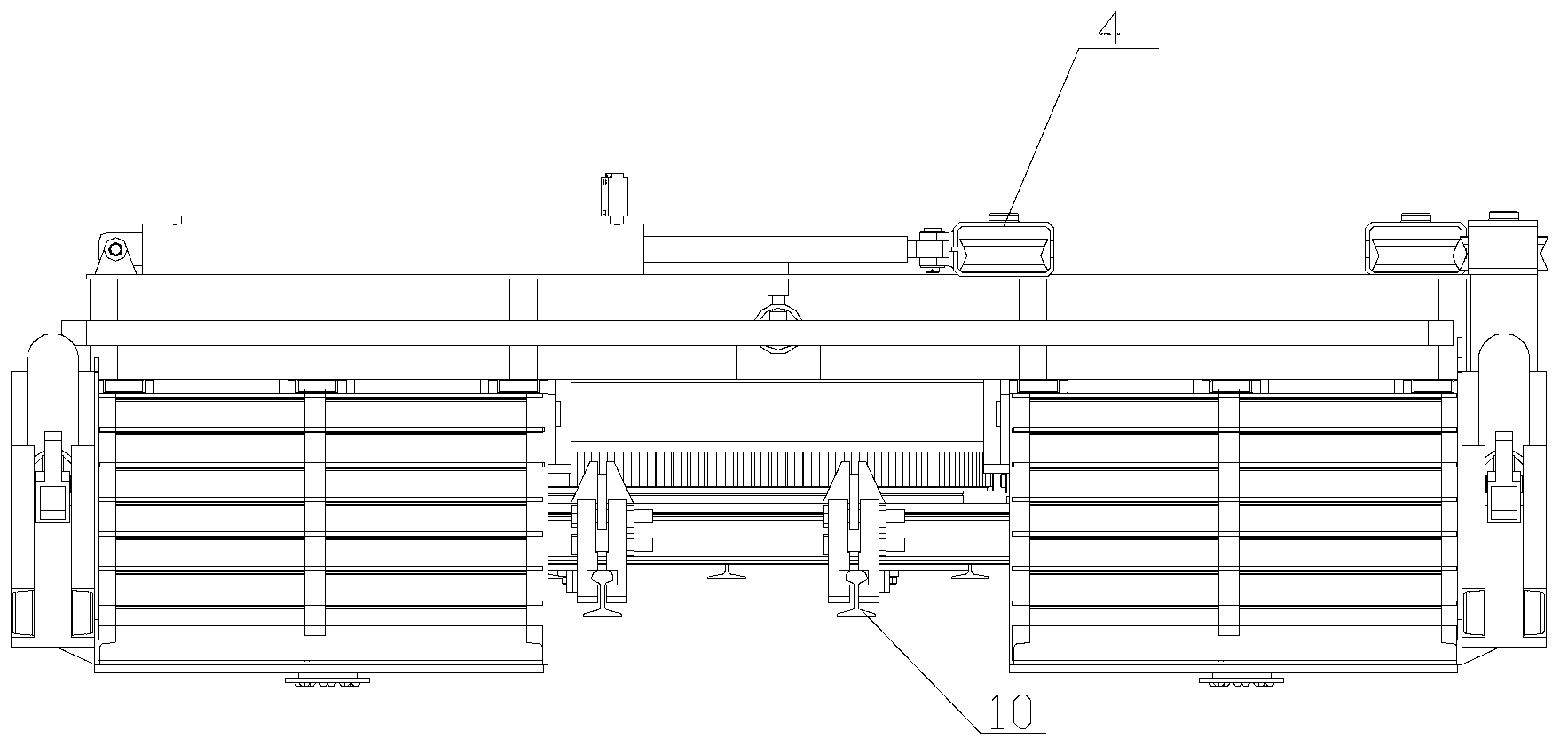

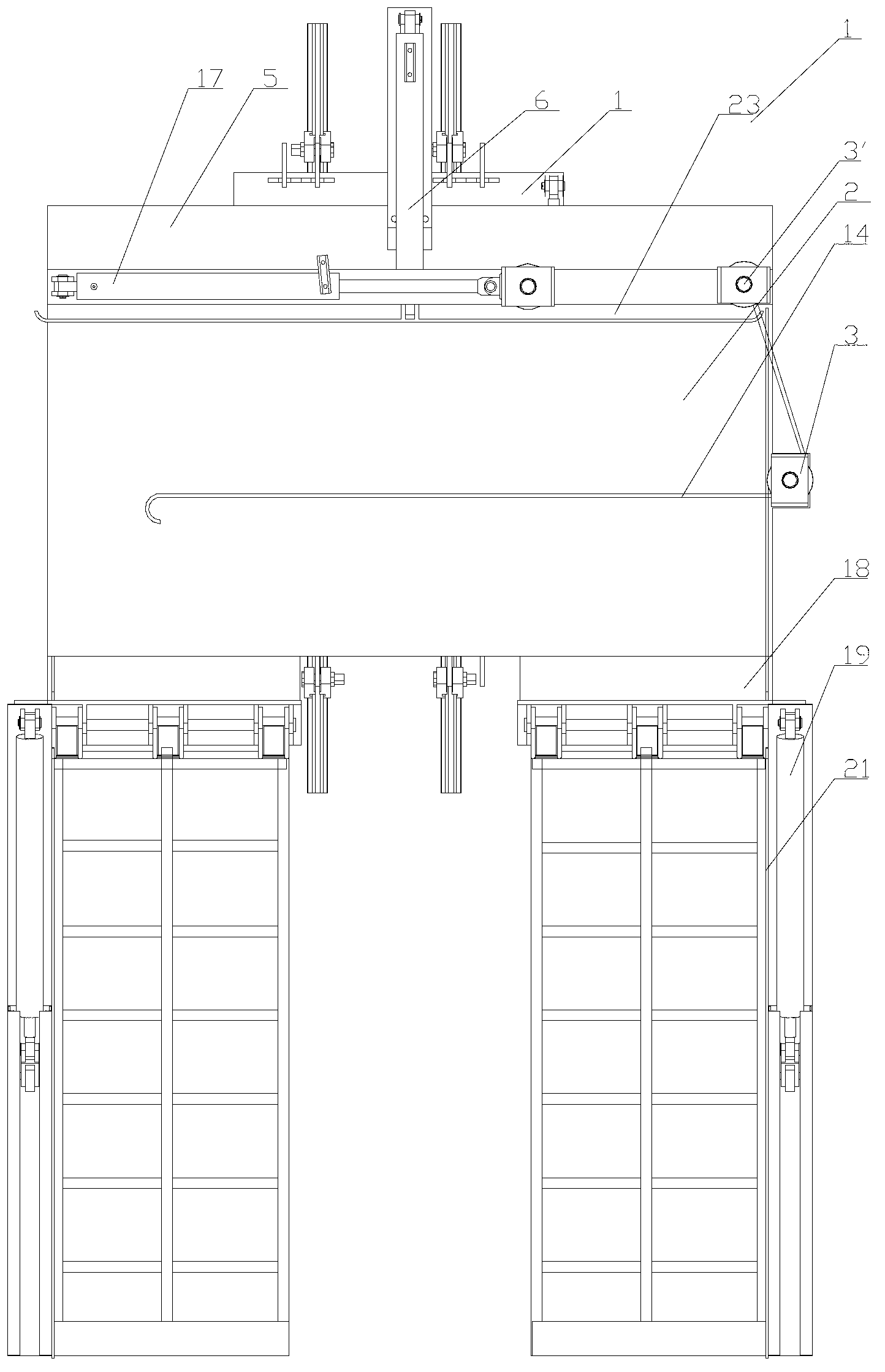

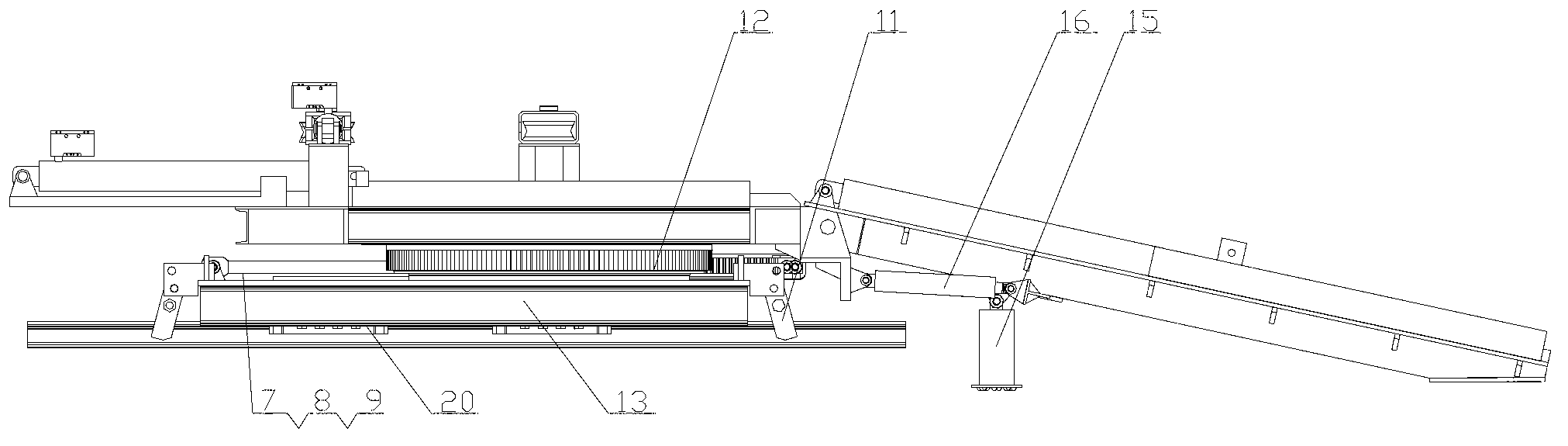

[0015] The rotary placement device for fully mechanized coal mining equipment provided in this embodiment has a structure such as Figure 1 to Figure 4 As shown, it includes a lower platform 13 and an upper platform 2 installed on the rail 10 via a shoe device 20, which can be interchanged and adjusted between a 600 or 900 gauge through the shoe device 20. The lower platform 13 and the upper platform 2 The slewing bearing 12 is connected by a rotating shaft 12, and the slewing bearing 12 is driven and connected by a slewing guide device, so that the slewing bearing 12 drives the upper platform 2 to rotate 90°; the opposite sides of the upper platform 2 are respectively installed with a bracket push-pull device 5 and a carriage rotation support device 1 , The support push-pull device 5 is connected to the upper platform 2 via the support 23, and the carriage rotation support device 1 is connected to the upper platform 2 via the connection seat 18.

[0016] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com