Top-mounted ultra-low temperature ball valve

An ultra-low temperature, top-mounted technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as difficult to achieve sealing effects, achieve low cost, ensure sealing, and reliable sealing of valve seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

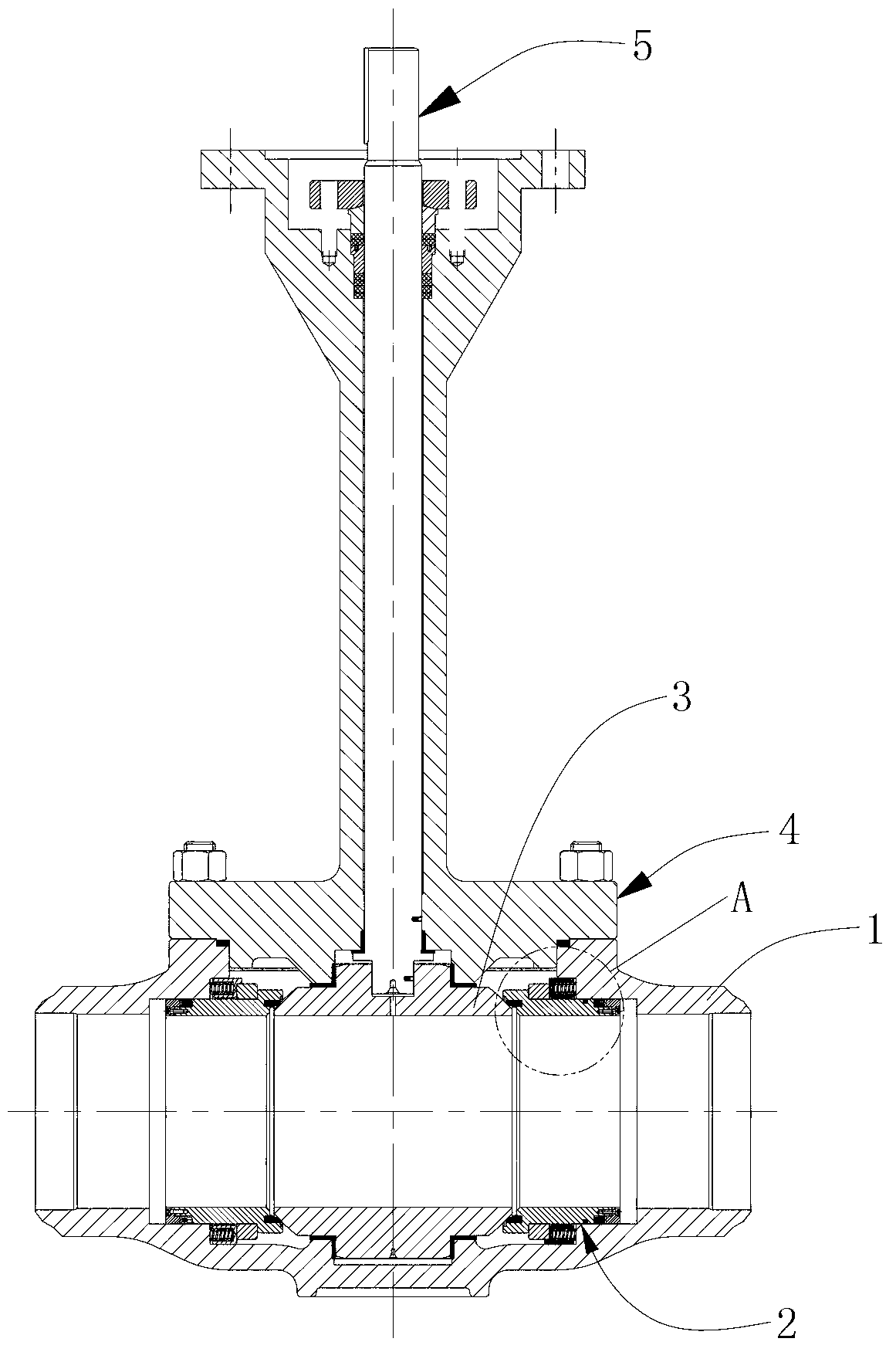

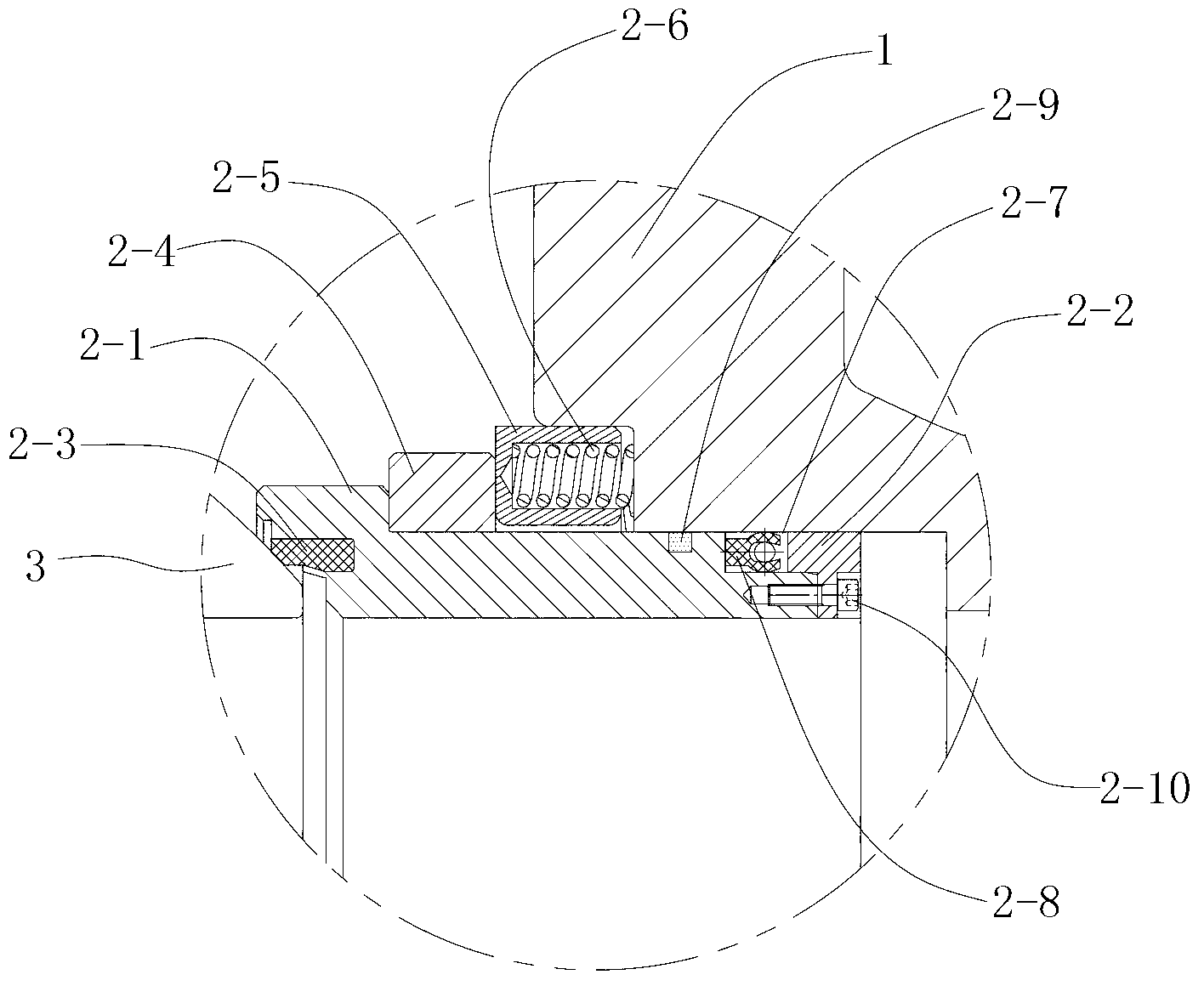

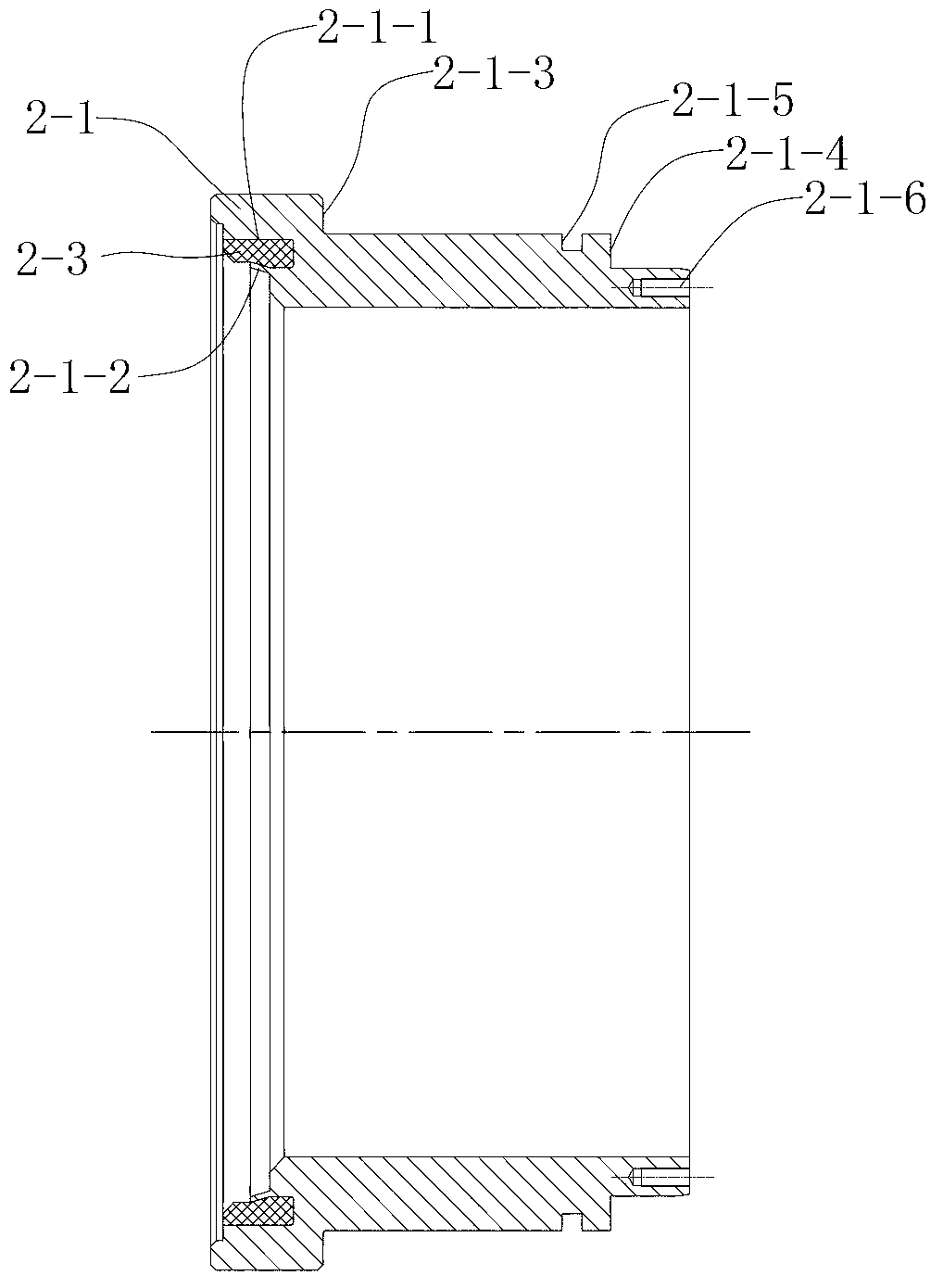

[0021] see Figure 1-4 , a top-entry ultra-low temperature ball valve, including a valve body 1, a valve seat assembly 2, a valve ball 3, a valve cover assembly 4 and a valve stem assembly 5. The valve seat assembly includes a valve seat ring 2-1 and a pressure ring 2-2 fixed on the end of the valve seat ring away from the valve ball. The end of the valve seat ring close to the valve ball is provided with a first installation groove 2-1-1, a sealing ring 2-3 is embedded in the installation groove, and a compression sealing ring is provided on the valve seat ring The inner ring fixes it with flanging 2-1-2. Specifically, during installation, the sealing ring is first installed in the first installation groove, and then the part of the seat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com