Fire prevention device for front feed device of biomass electricity generation furnace

A technology of feeding device and fire prevention device, which is applied in the direction of fuel supply, combustion method, block/powder supply/distribution, etc. It can solve the problems of no fire prevention effect and inability to respond in time by itself, and achieves simple structure and easy maintenance. And the effect of low maintenance cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

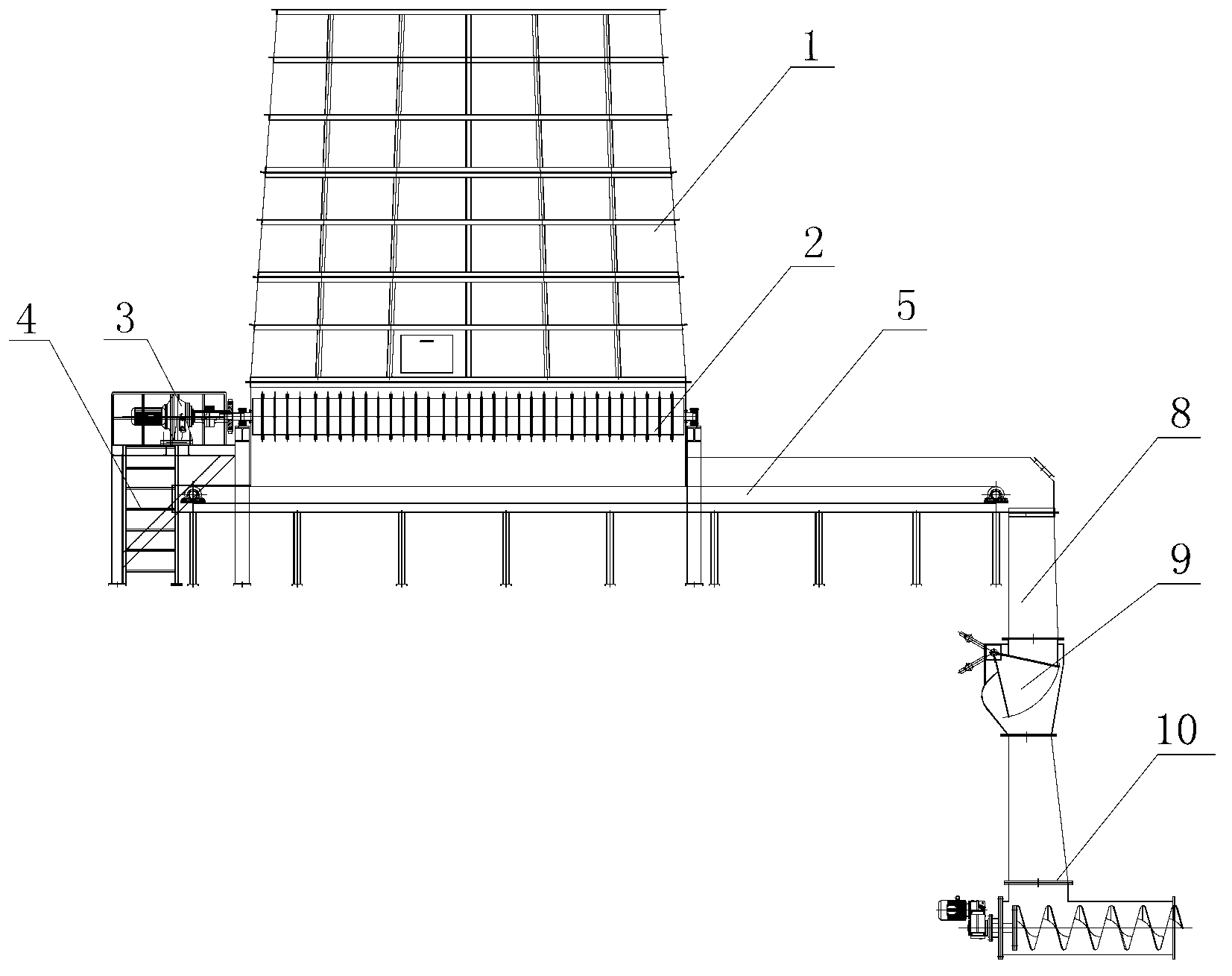

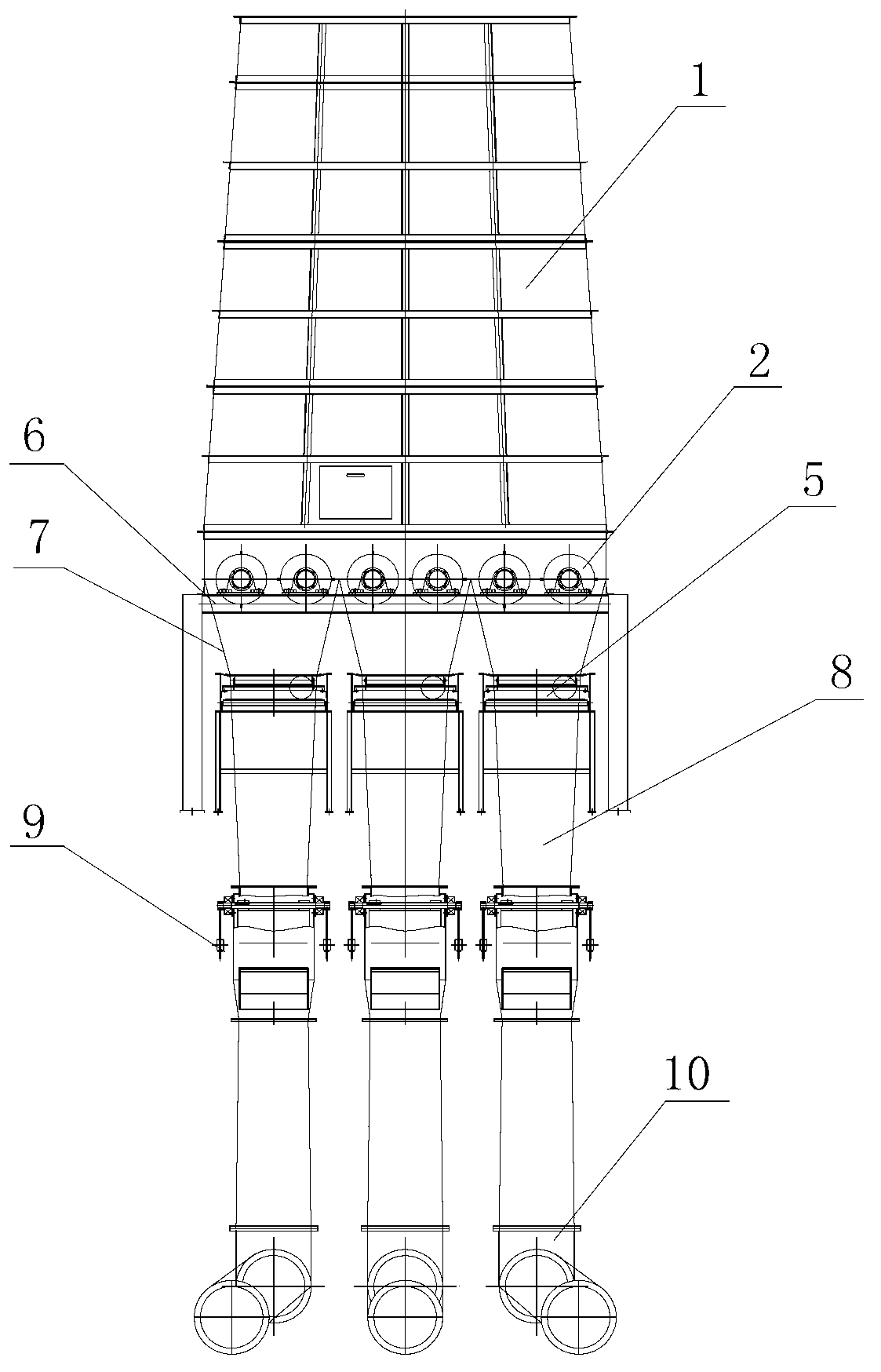

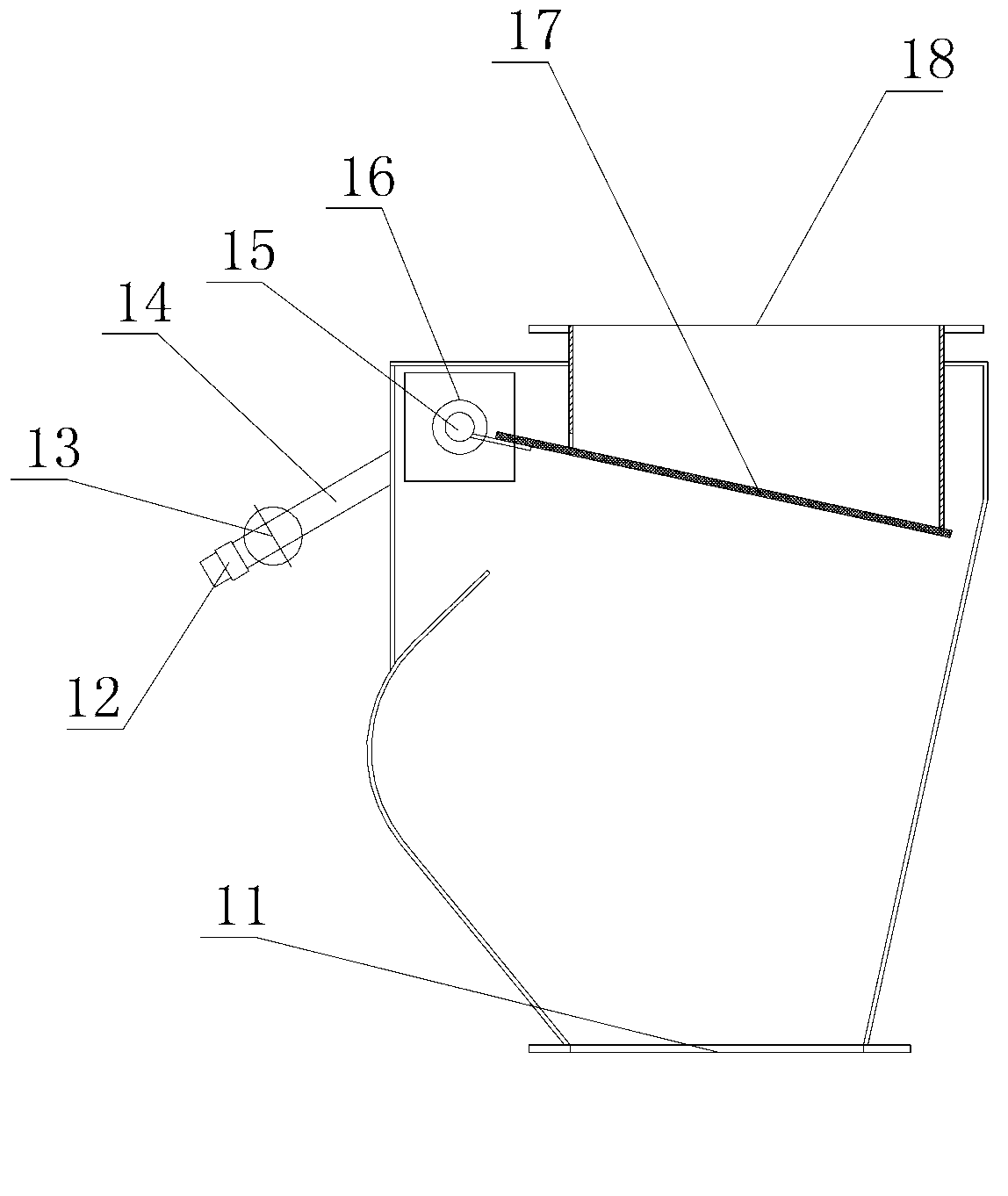

[0022] Such as figure 1 As shown, a fireproof device for a feeding device in front of a biomass power furnace includes a silo support 6 and a silo main body 1 disposed on the silo support 6 , and an escalator 4 is provided on one side of the silo support 6 . A closed conveying device 5 is arranged on the bin support 6, and the closed conveying device 5 communicates with a shaftless screw machine 10 through a slide pipe 8. The main body 1 of the silo is provided with a front feeding device 2 connected with a driving device 3 , and the front feeding device 2 cooperates with a closed conveying device 5 . A buffer bin 7 is arranged between the closed conveying device 5 and the front feeding device 2 . The above-mentioned silo main body 1, front feeding device 2, driving device escalator 4, closed conveying device 5, silo support 6, buffer bin 7, chute 8 and shaftless screw machine 10 all belong to the prior art, and their respective The shape, structure, and positional relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com