Leakage detector

The technology of a leak detector and a cover is applied in the field of natural gas engine testing equipment, and can solve the problems of untargeted detection, inability to detect nozzles, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

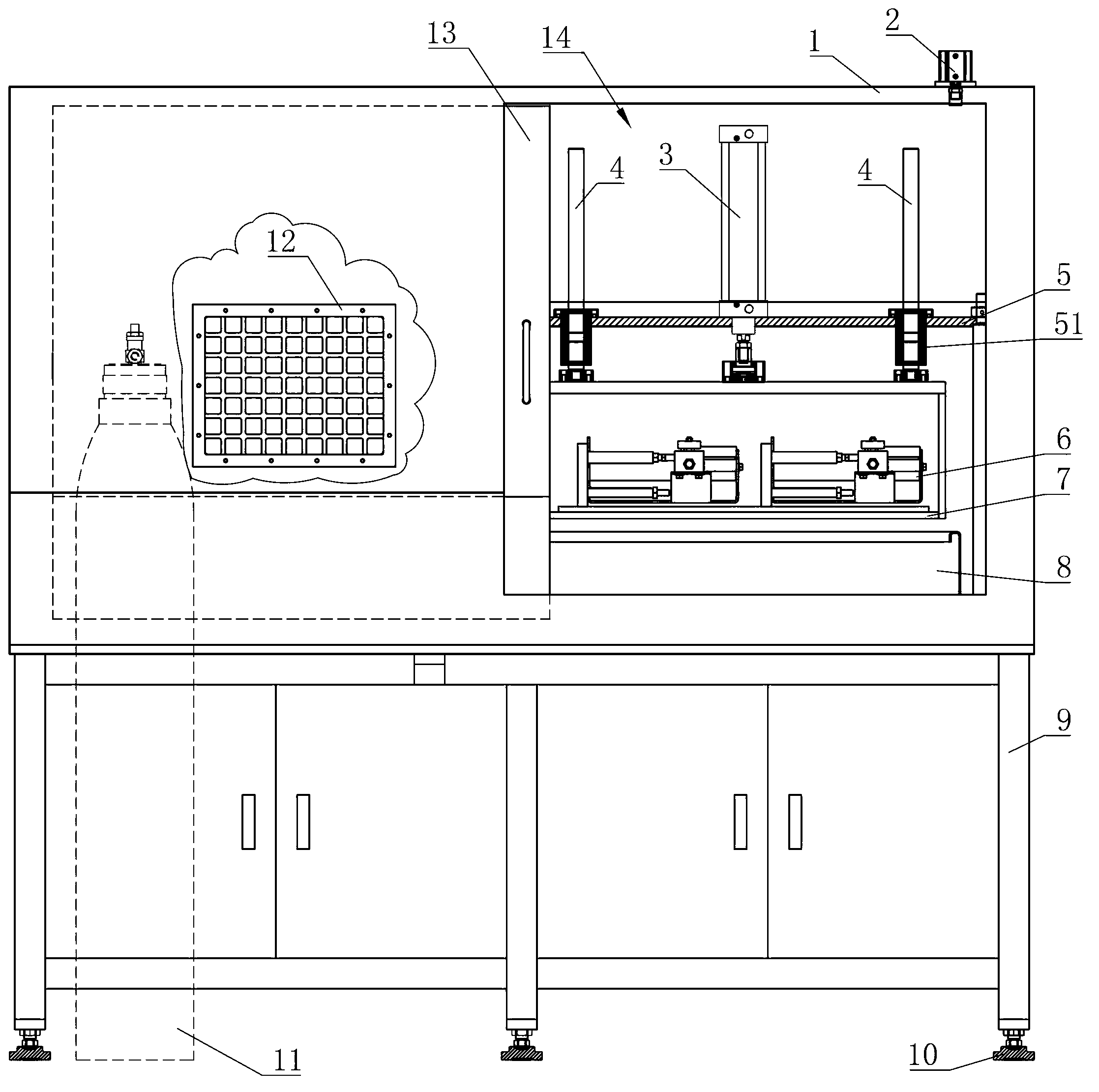

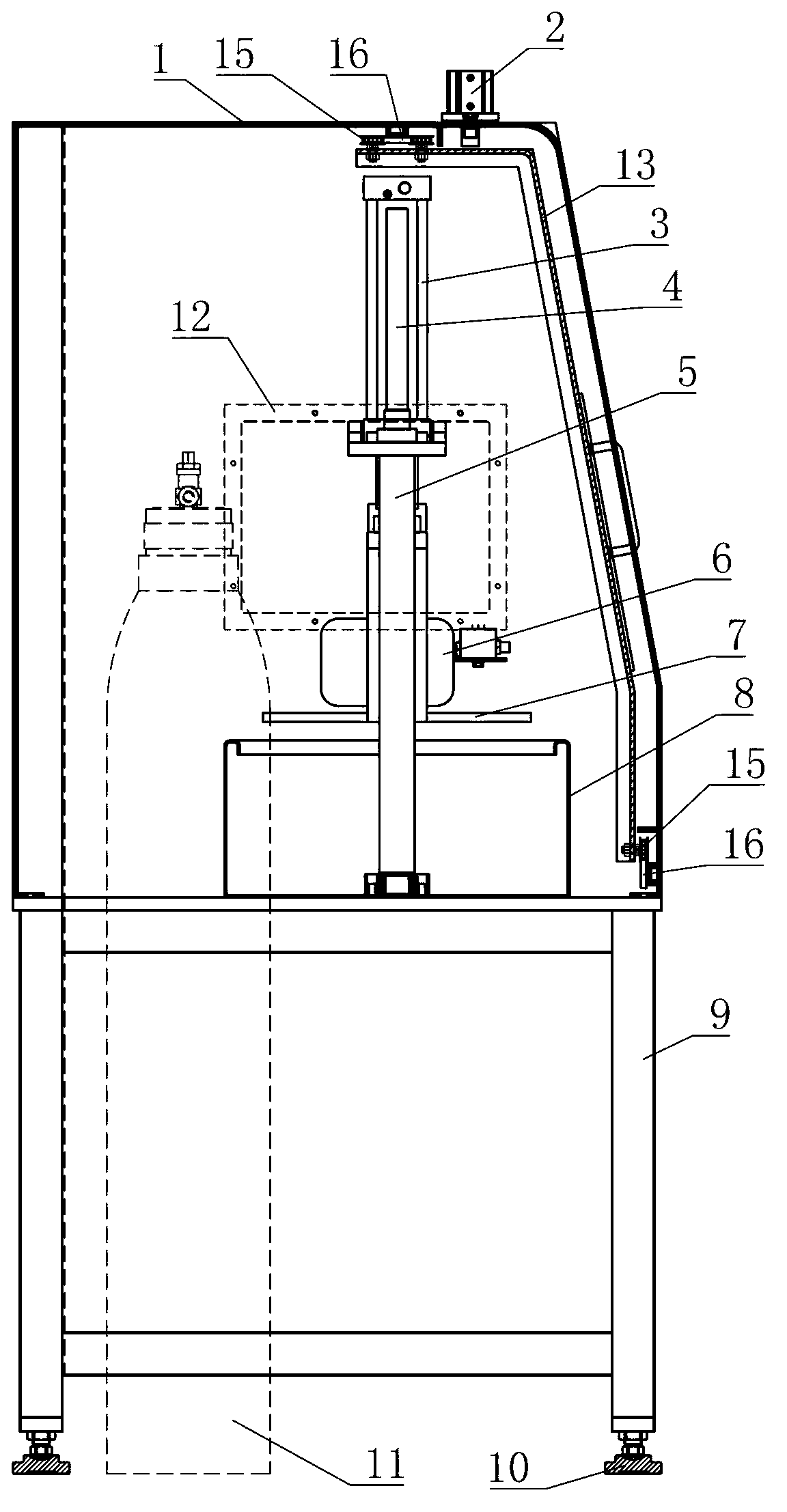

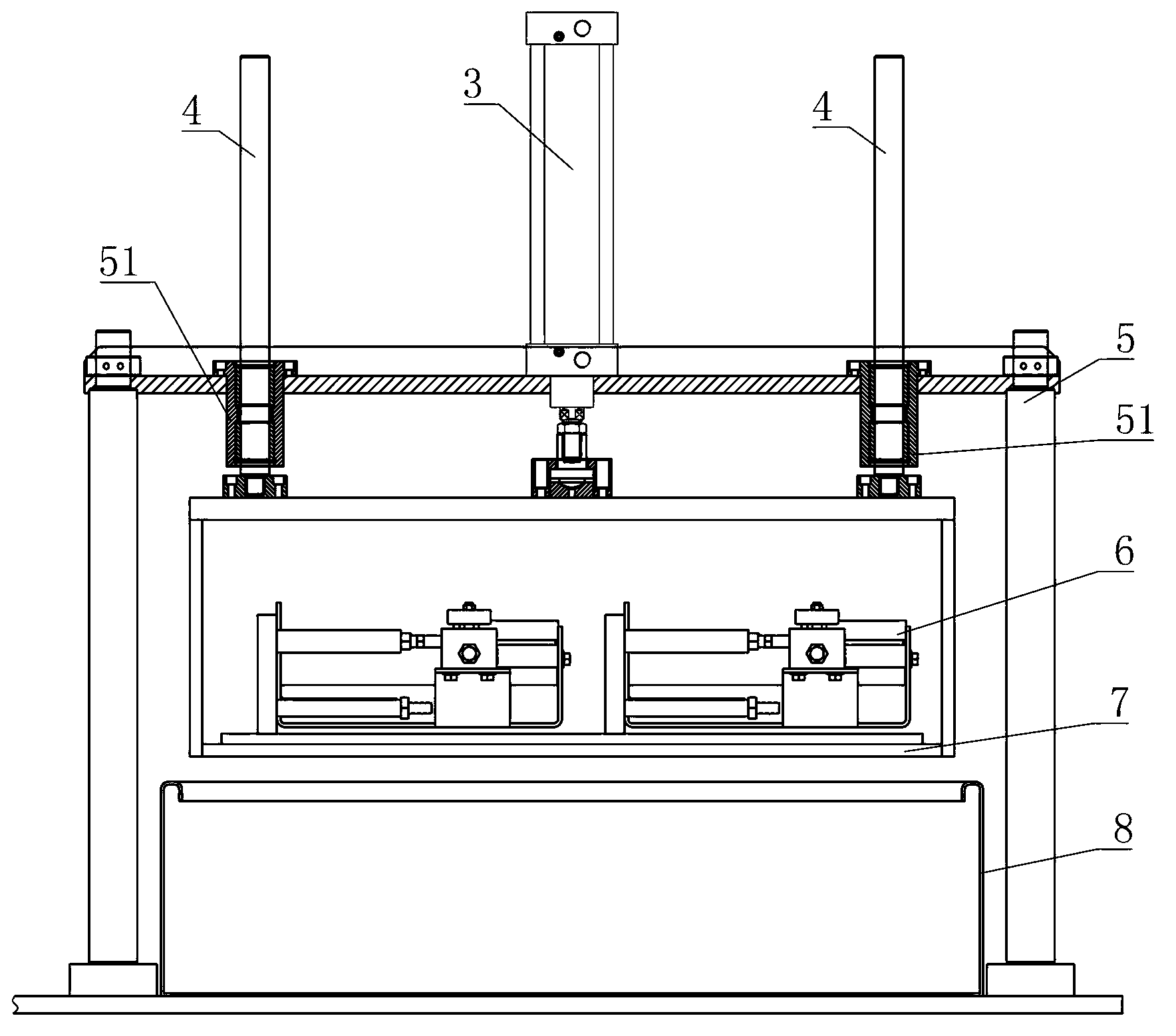

[0017] Such as figure 1 and figure 2 As shown, a leak detector includes a case 1, a support 9 is provided under the case 1, and a foot 10 is provided at the bottom of the support 9, and a water tank 8 is installed in the case 1, so that The water tank 8 is usually made of a transparent material, a lifting device for placing the gas component 6 to be tested is arranged above the water tank 8, and a gas chamber for providing compressed gas for the gas component 6 to be tested is also provided in the casing 1 . source, the casing 1 is provided with an opening 14 for the gas component 6 to enter and exit, the opening 14 is provided with a safety door 13, and the casing 1 is also provided with a window for observing the gas component 6 in the water tank 8 Observation window 12, in order to protect the safety of observers, described observation window 12 generally adopts explosion-proof observation window 12, and described opening 14 is positioned at the front of described casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com