Magnet measuring device and magnet measuring method

A technology of measuring device and measuring method, which is applied in the direction of measuring device, measuring magnetic variables, the magnitude/direction of magnetic field, etc., can solve the problems of magnetic field attenuation, lack of processing of phase difference, deviation of measurement results, etc., and achieve the purpose of overcoming air gap instability or The effects of oversize, fast sampling and quality control, and improved consistency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

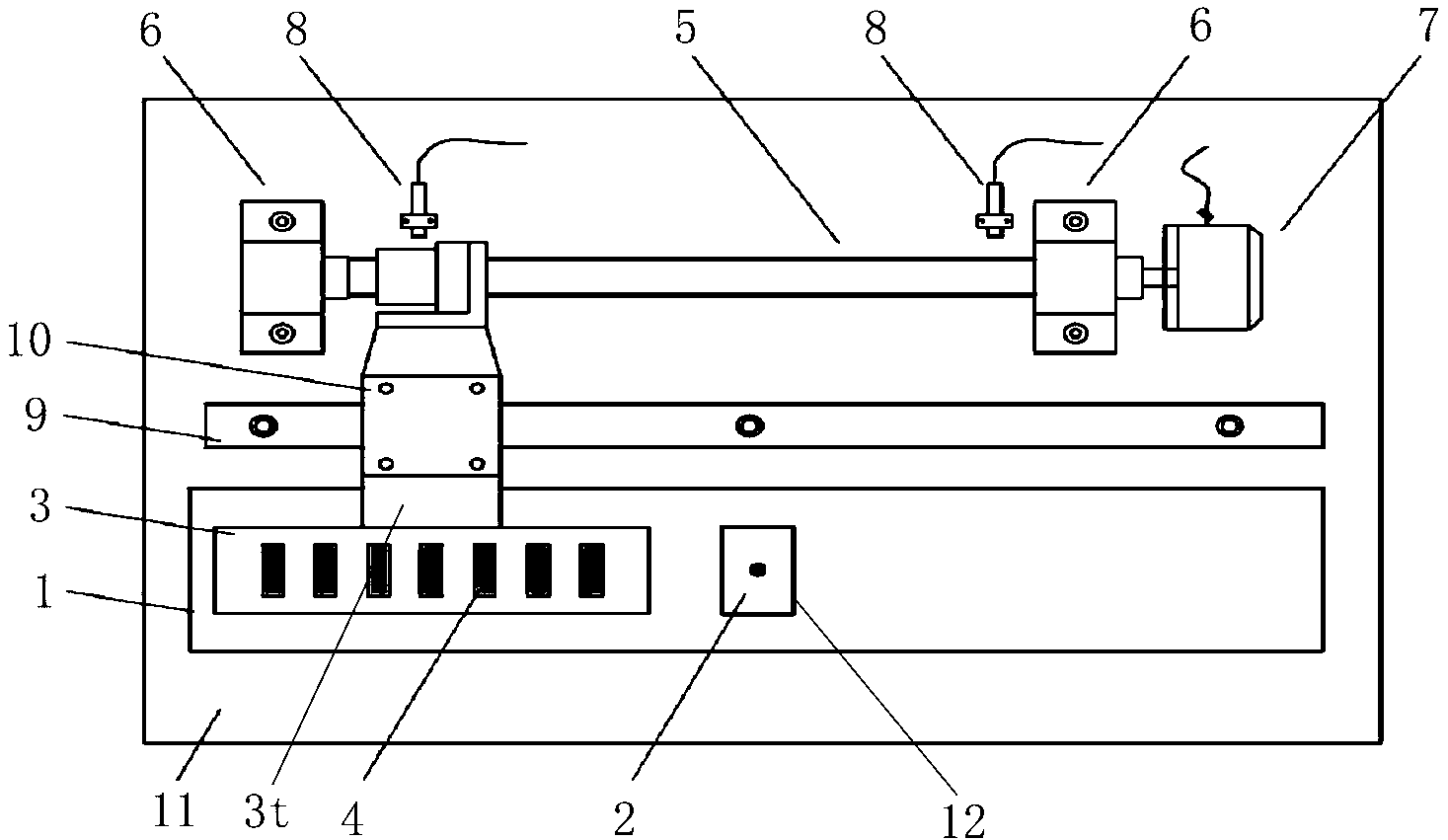

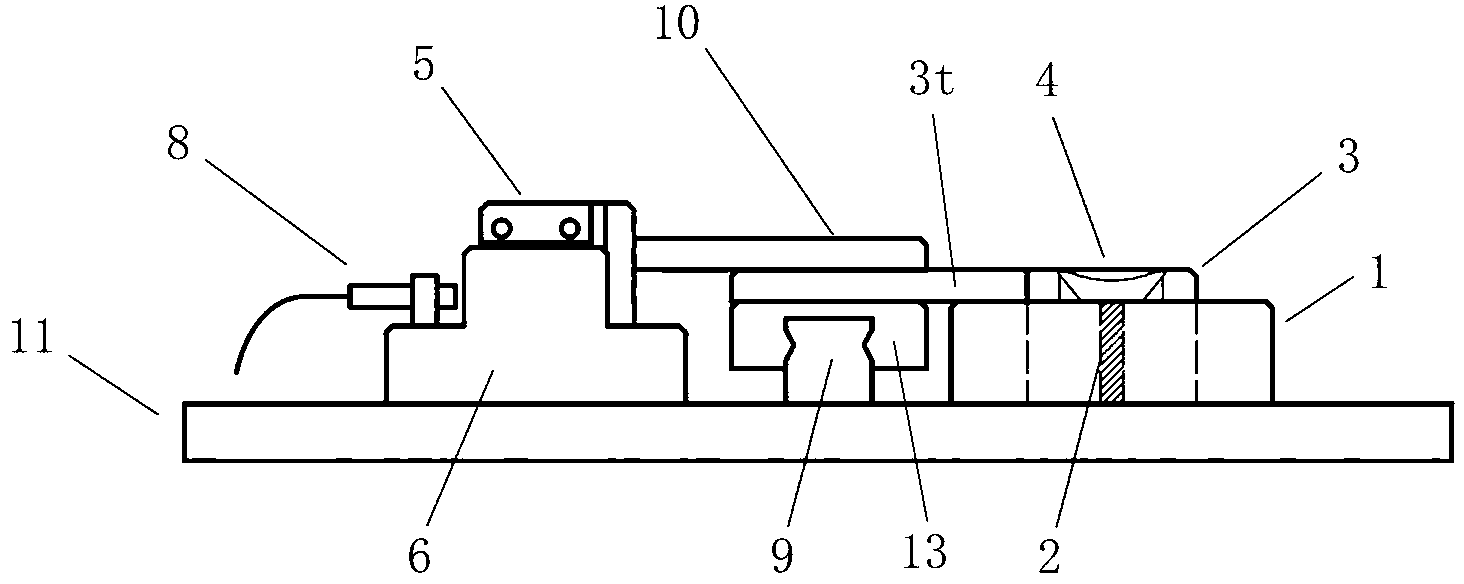

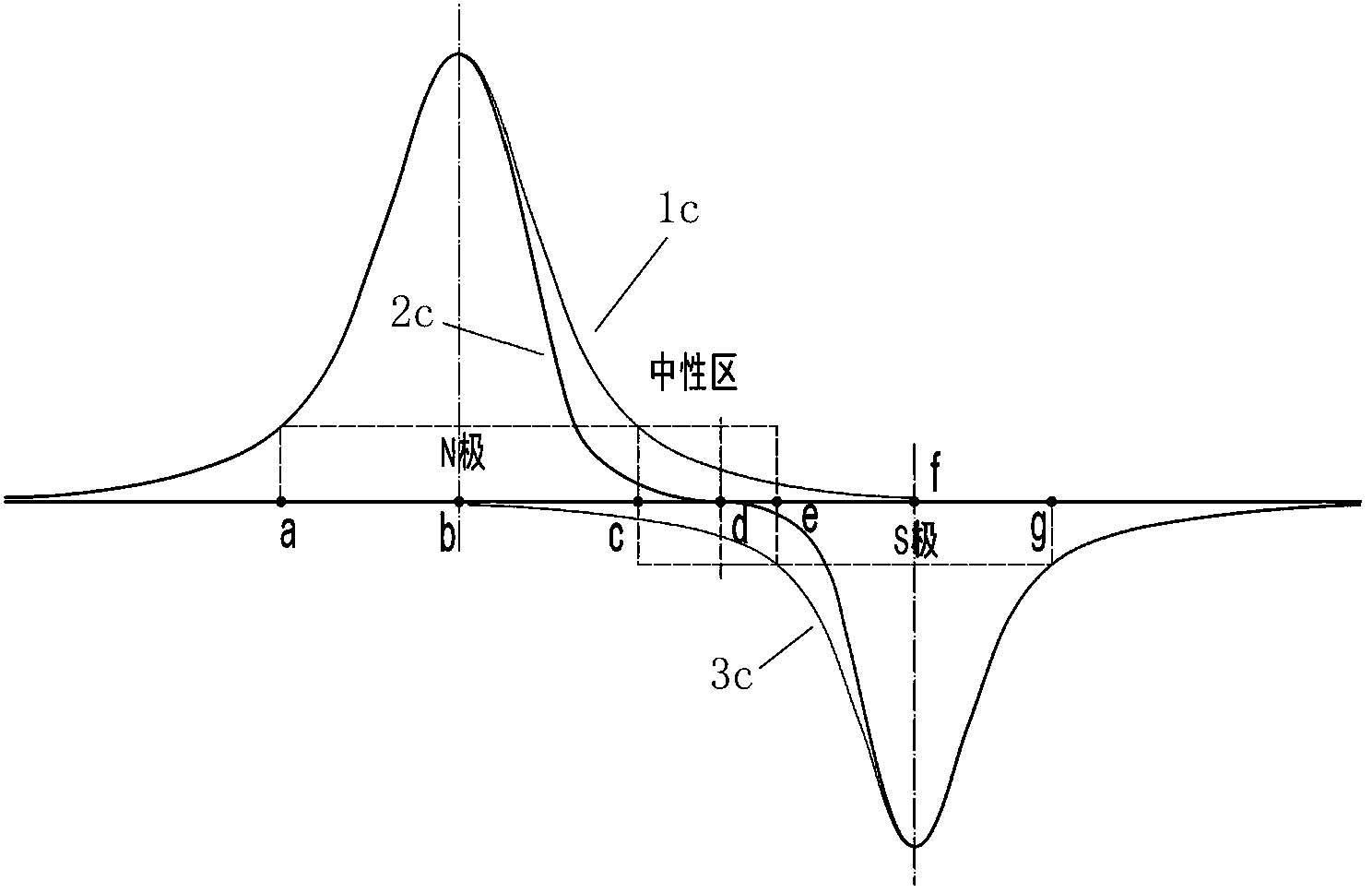

[0049] figure 1 is a top view of a neutral zone measuring device according to an embodiment of the present application; figure 2 It is a left view of the neutral zone measurement device according to the embodiment of the present application. like figure 1 , figure 2 As shown, the magnet neutral region measuring device proposed by the present invention includes: a lead screw 5, which has a screw and a nut; a motor 7, which is used to drive the screw in the lead screw 5 to rotate; a measuring platform 1, on which a probe is arranged Hole 12; Magnet positioning plate 3, wherein is provided with positioning hole 4, and positioning hole 4 is used for placing the magnet to be measured, and magnet positioning plate 3 moves on measuring platform 1 along with the movement of the nut of leading screw 5; Hall probe block 2. A Hall sensor is installed inside to meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com