Device for vacuum packaging, particularly of food products

A technology for food and equipment, applied in the field of packaging equipment, can solve the problems of bad appearance of packaging, machine parking, incorrect arrangement of slices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

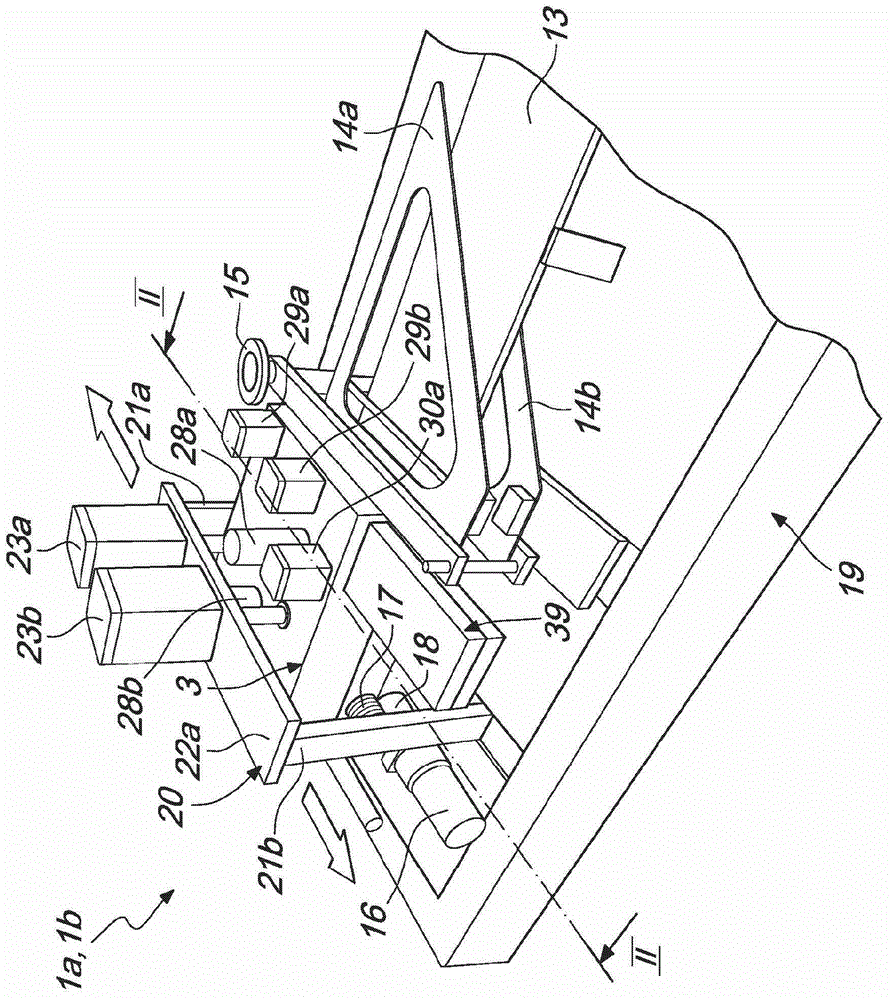

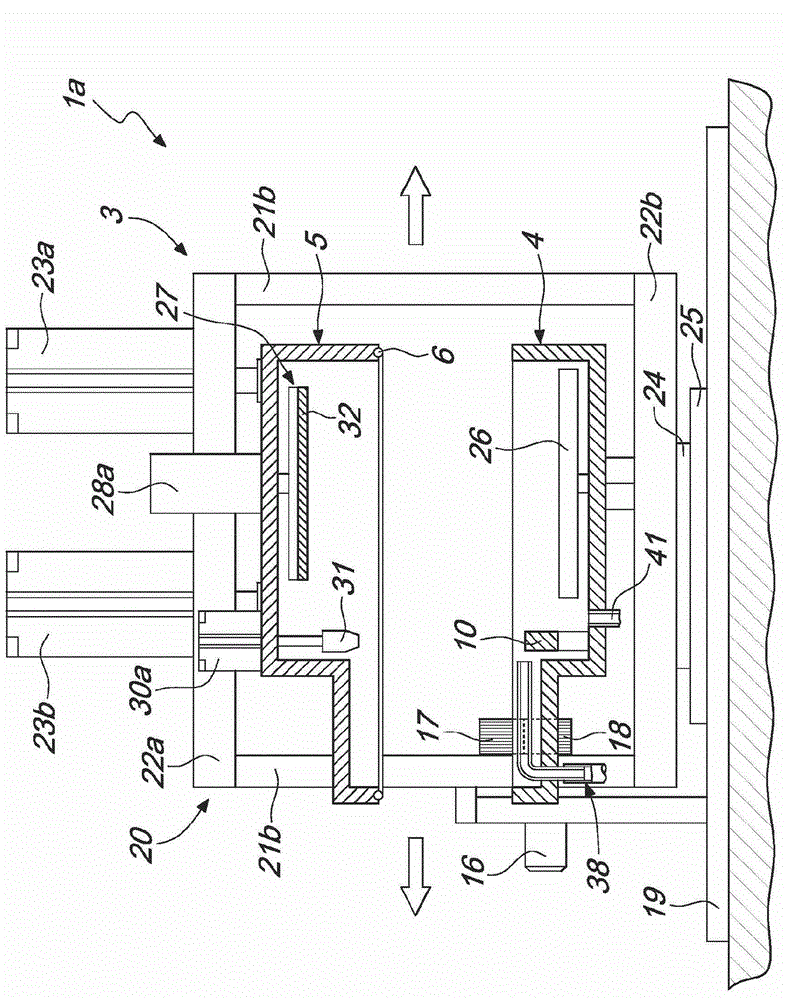

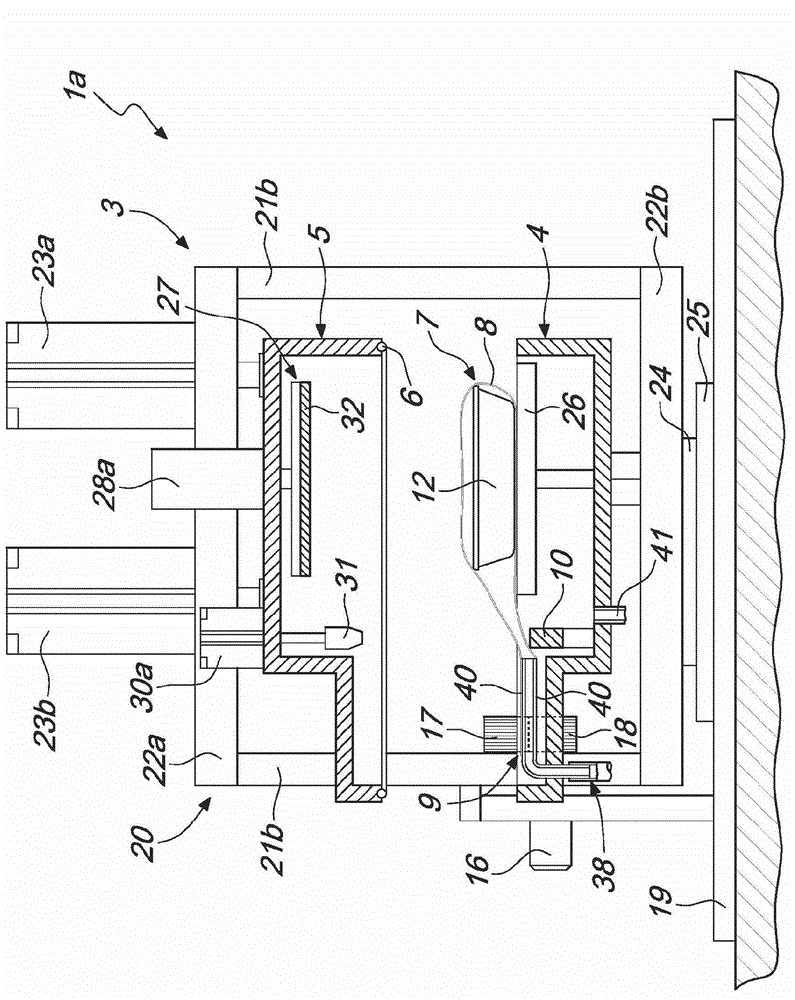

[0043] refer to Figures 1 to 7 , the reference numeral 1a denotes a packaging device especially for industrial materials or food, and the industrial material or food is denoted by the reference numeral 2 .

[0044] Apparatus 1a comprises a bell-shaped vacuum chamber, indicated by reference numeral 3, which essentially consists of a lower container 4 and a closable upper lid 5; a band or gasket 6 for airtightness surrounds the container 4 and Perimeter arrangement of cover 5 .

[0045] The device uses a single-fold film 7 , which thus has a closed first longitudinal side 8 and an open second longitudinal side 9 .

[0046]An L-shaped first heat-sealing bar 10 is arranged in the bell-shaped vacuum chamber 3, with one side adjacent to the food inlet 11; a substantially L-shaped cutting blade (not shown) is laterally adjacent to the first heat-sealing bar 10, and the two straight lines of the shape L are arranged parallel to and perpendicular to the first heat-sealing rod 10, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com