slave cylinder

A friction clutch, hydraulic technology, used in engine components, engine seals, fluid-driven clutches, etc., can solve problems such as piston stuck, system failure, tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

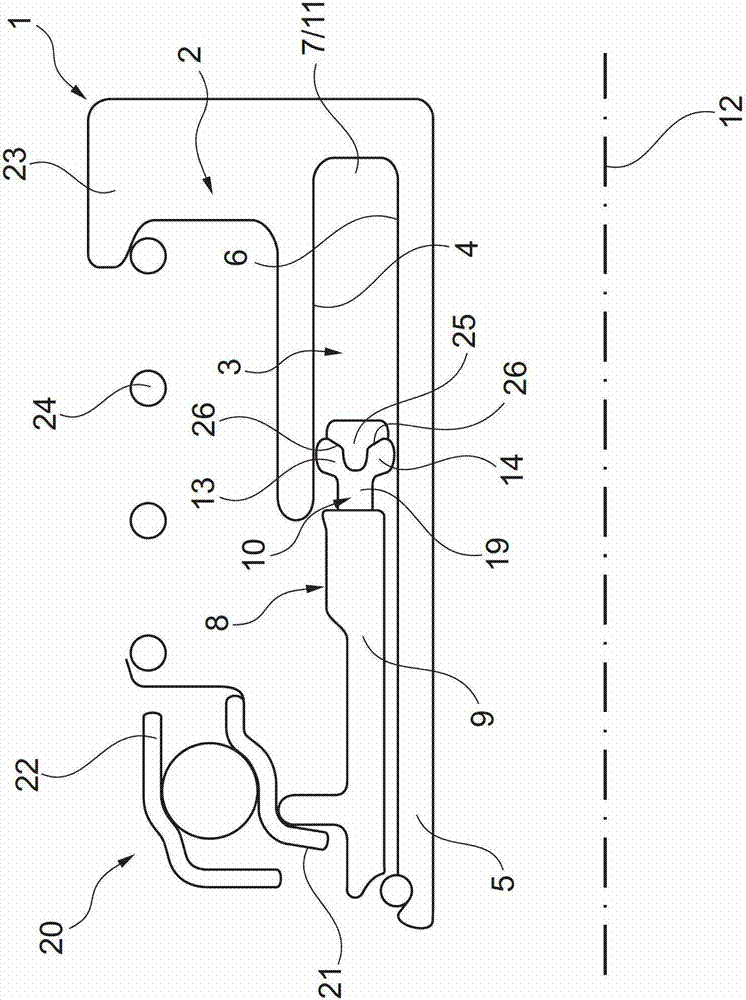

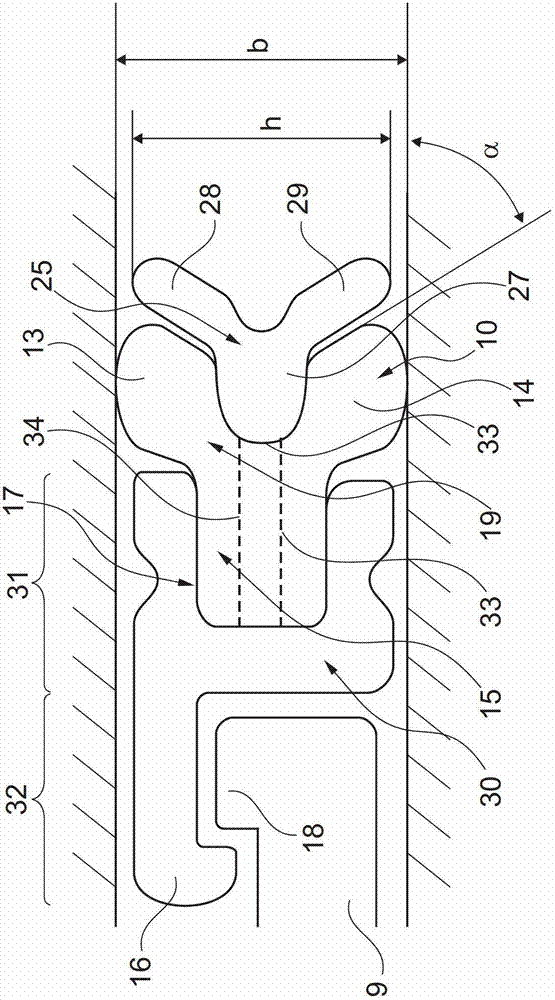

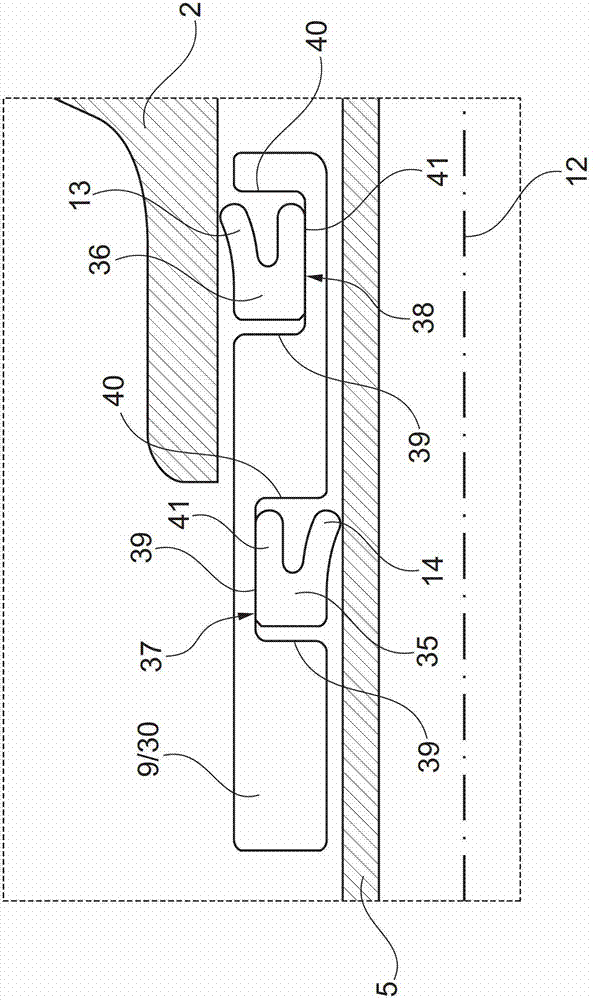

[0023] figure 1 A partial partial sectional view of a slave cylinder 1 is shown. The slave cylinder comprises a slave cylinder housing 2 having an elongated bore 3 with a substantially cylindrical inner face, and a guide with a likewise cylindrical outer face 6 Sleeve 5. An annular space 7 is enclosed between the inner surface 4 of the slave cylinder housing 2 and the outer surface 6 of the guide sleeve 5 , in which an annular piston 8 is arranged. The annular piston 8 includes a piston head 9 and a seal 10 . The sealing device 10 encloses a pressure chamber 11 together with the slave cylinder housing 2 and the guide sleeve 5 . The slave cylinder is arranged concentrically around a transmission input shaft at figure 1 is shown only schematically with the aid of the axis of rotation 12 of the transmission input shaft. exist figure 1 In , the radial direction is indicated by a double arrow R, and the axial direction is indicated by a double arrow A. The circumferential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com