A kind of light rubber material and its preparation method and shoe sole made of the material

A kind of rubber material, lightweight technology, applied in the direction of sole, footwear, application, etc., can solve the problem of not being able to participate in the vulcanization process of vulcanized rubber, reducing the tear strength of the sole material, weak interface bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

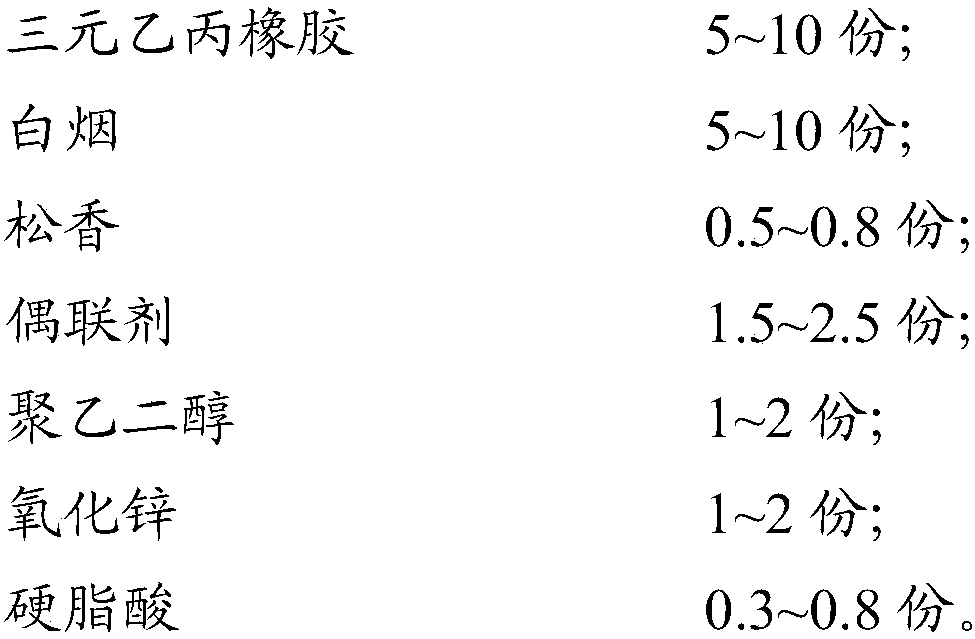

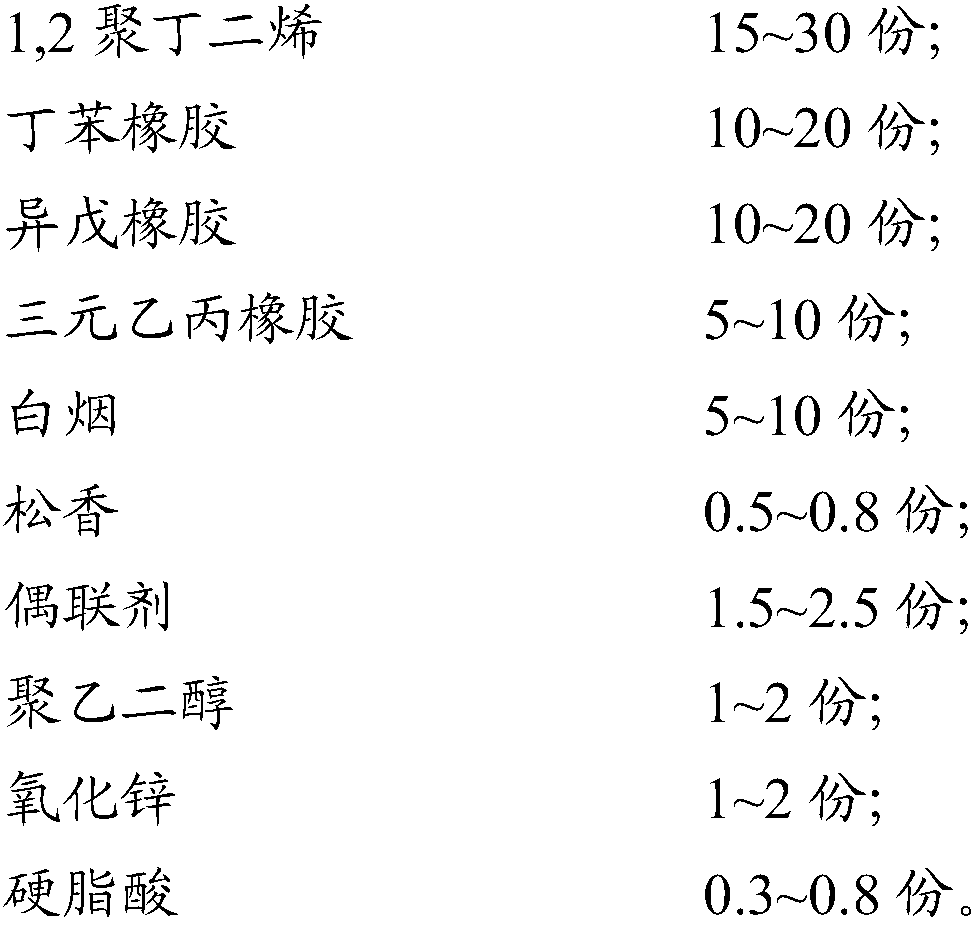

[0039] When the lightweight rubber material does not contain anti-aging agent and protective wax components, the present invention provides a method for preparing the above-mentioned lightweight rubber material, comprising the steps of:

[0040] Mix 1,2 polybutadiene, styrene-butadiene rubber, isoprene rubber, EPDM rubber, white smoke, rosin, coupling agent, polyethylene glycol, zinc oxide and stearic acid for internal mixing and open mixing, get base material;

[0041] The kneaded base material is mixed with sulfur and an accelerator for vulcanization to obtain a lightweight rubber material.

[0042] The invention mixes 1,2 polybutadiene, styrene-butadiene rubber, isoprene rubber, EPDM rubber, white smoke, rosin, coupling agent, polyethylene glycol, zinc oxide and stearic acid for banburying and development. Refining to obtain the base material. In the present invention, there is no special requirement on the order of feeding the raw materials, and the mixing can be perform...

Embodiment 1

[0055]

[0056] mixing 1,2 polybutadiene, styrene-butadiene rubber, isoprene rubber, EPDM rubber, white smoke, rosin, coupling agent, polyethylene glycol, zinc oxide and stearic acid to obtain a compound;

[0057] The mixture is banburyed under 1.5MPa pressure: the time of banburying in the first stage is 7 minutes, the time of banburying in the second stage is 5 minutes, the time of banburying in the third stage is 4 minutes, and the time of banburying in the fourth stage The time for banburying is 2 minutes, and the interval between banburying is 15 seconds.

[0058] The mixed material after banburying is carried out kneading until the thickness of the base material is 6mm, and it is allowed to stand at room temperature for 24 hours.

[0059] The base material after kneading was mixed with sulfur and accelerator according to the mass ratio of 1000:12:7 for vulcanization, the vulcanization temperature was 155°C, the pressing force was 130kg, and the time was 3 minutes to o...

Embodiment 2

[0061]

[0062] mixing 1,2 polybutadiene, styrene-butadiene rubber, isoprene rubber, EPDM rubber, white smoke, rosin, coupling agent, polyethylene glycol, zinc oxide and stearic acid to obtain a compound;

[0063] The compound is banburyed under 1MPa pressure: the time of the first stage banburying is 12 minutes, the time of the second stage banburying is 5 minutes, the time of the third stage banburying is 3 minutes, the time of the fourth stage banburying The refining time is 1 minute, and the interval between banburying is 30 seconds.

[0064] The mixed material after banburying was carried out kneading until the thickness of the base material was 8mm, and it was allowed to stand at room temperature for 24 hours.

[0065] The base material after kneading is mixed with sulfur and accelerator according to the mass ratio of 1000:14:9 for vulcanization. The vulcanization temperature is 155°C, the pressing force is 120kg, and the time is 5 minutes to obtain a light rubber mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com