A preparation method of whisker self-toughened α-sialon ceramic material

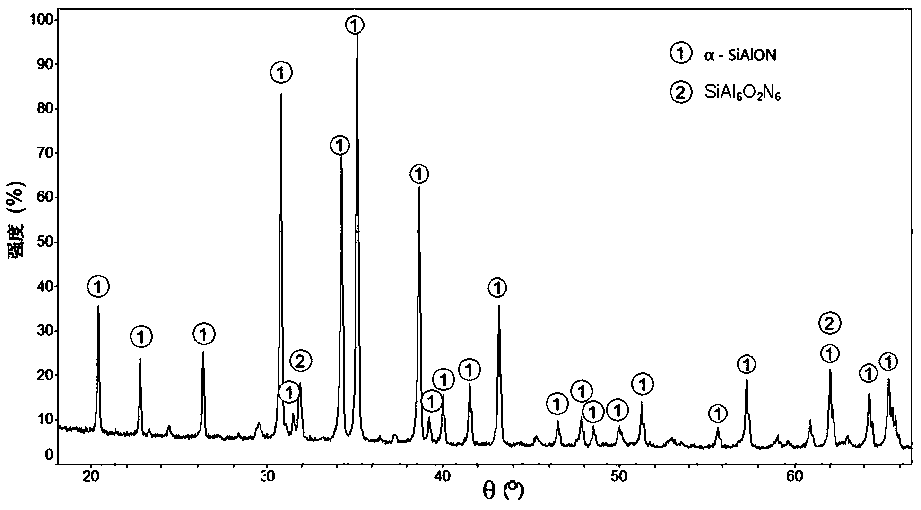

A ceramic material and self-toughening technology, which is applied in the preparation field of whisker self-toughened α-SiAlON ceramic materials, can solve the problems of low flexural strength and insufficient toughness of α-Sialon ceramics, achieve less impurity phases, improve Excellent flexural strength, fracture toughness, and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of whisker self-toughening α-SiAlON ceramic material of the present invention, comprises the following steps:

[0032] (1) Ingredients: According to the molecular formula Y m / 3 Si 12-(m+n) Al m+n o n N 16-n The stoichiometric ratio of weighing raw material powder α-Si 3 N 4 、Al 2 o 3 , Y 2 o 3 and AlN polytype powder, where m=0.3, n=0.6.

[0033] In this embodiment, the chemical composition of the AlN polytype powder is SiAl 5 o 2 N 5 , the preparation process is as follows: the raw materials Al, Si, Al 2 o 3 powder by SiAl 5 o 2 N 5 Carry out molar ratio, and add pore-forming agent (such as NH 4 F, etc., a small amount) mixed, in a nitrogen atmosphere, at 1600 ° C for 12 hours to obtain the AlN polytype.

[0034] (2) Preparation of mixed powder (including glue mixing): mix the raw material powder prepared in step (1) for ball milling, and at the same time add a molding agent (that is, glue mixing), and the molding agent accounts ...

Embodiment 2

[0040] A preparation method of whisker self-toughening α-SiAlON ceramic material of the present invention, comprises the following steps:

[0041] (1) Ingredients: According to the molecular formula Y m / 3 Si 12-(m+n) Al m+n o n N 16-n Weigh raw material powder α-Si 3 N 4 、Al 2 o 3 , Y 2 o 3 And AlN polytype, in the formula, m=0.6, n=0.8.

[0042] In this example, the chemical composition of the AlN polytype is SiAl 6 o 2 N 6 , the preparation process is as follows: the raw materials Al, Si, Al 2 o 3 powder by SiAl 6 o 2 N 6 Carry out molar ratio, and add pore-forming agent (such as NH 4 F, etc., a small amount) mixed, in a nitrogen atmosphere, at 1600 ° C for 12 hours to obtain the AlN polytype.

[0043] (2) Preparation of mixed powder: mix the raw material powder (i.e. powder) prepared in step (1) and perform ball milling, and at the same time add a molding agent (polyvinyl alcohol), and the molding agent accounts for the mass fraction of the obtained mixed...

Embodiment 3

[0049] A preparation method of whisker self-toughening α-SiAlON ceramic material of the present invention, comprises the following steps:

[0050] (1) Ingredients: According to the molecular formula Y m / 3 Si 12-(m+n) Al m+n o n N 16-n Weigh raw material powder α-Si 3 N 4 、Al 2 o 3 , Y 2 o 3 and AlN polytype powder, in the formula, m=0.6, n=0.6.

[0051] In this embodiment, the chemical composition of the AlN polytype powder is SiAl 8 o 2 N 8 , the preparation process is as follows: the raw materials Al, Si, Al 2 o 3 powder by SiAl 8 o 2 N 8 Carry out molar ratio, and add pore-forming agent (such as NH 4 F, etc., a small amount) mixed, in a nitrogen atmosphere, at 1600 ° C for 12 hours to obtain the AlN polytype.

[0052] (2) Preparation of mixed powder: Mix the raw material powders prepared in step (1) and then perform ball milling. At the same time, add a molding agent (polyvinyl alcohol). The mass fraction of the molding agent in the obtained mixed powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com