Electrowetting display device

An electrowetting display and electrowetting technology, which is applied in the directions of instruments, light guides, optics, etc., can solve the problems of unsatisfactory quality of display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

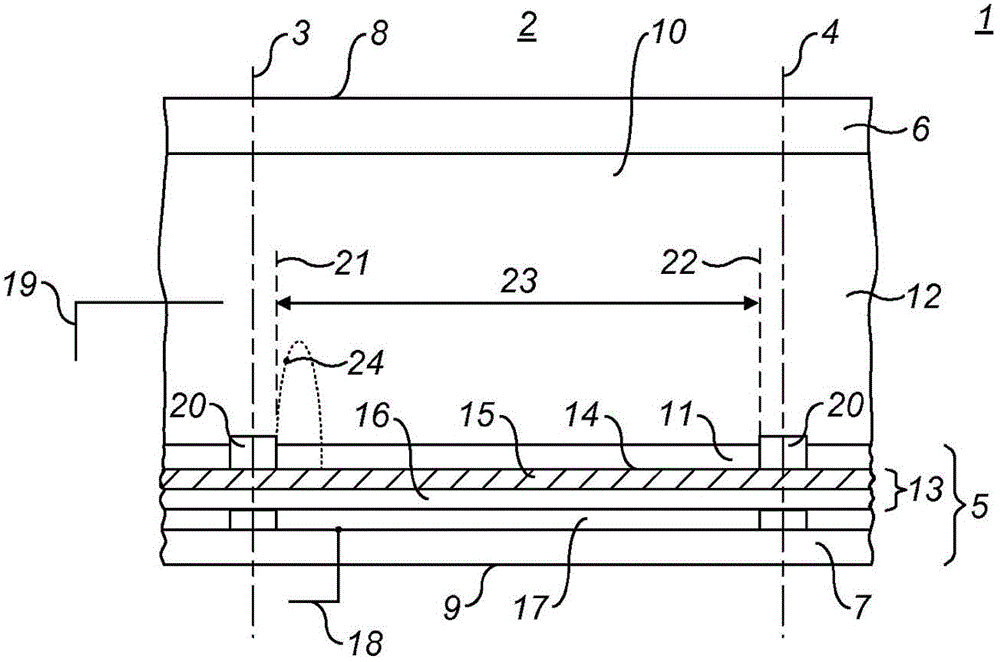

[0028] figure 1 A diagrammatic cross-section of part of an electrowetting device is shown in the form of an electrowetting display device 1 . The display device comprises a plurality of picture elements 2, one of which is shown in the figure. The lateral extent of a cell is indicated by two dashed lines 3, 4 in the figure. The pixel includes a first support plate 5 and a second support plate 6 . These support plates may be separate components of each cell, but preferably they are shared by multiple cells. The support plate may comprise glass or polymer substrates 6, 7 and may be rigid or flexible.

[0029] The display device has a viewing face 8 and a rear face 9 on which images or displays formed by the display device can be viewed. In the figure, the first support plate 5 faces the back 9; the second support plate 6 faces the viewing surface; alternatively, the first support plate can face the viewing surface. Display devices may be reflective, transmissive, or transfle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com