Method for producing container-packed aloe leaf pulp, and aloe leaf pulp

A technology of aloe mesophyll and container, which is applied in application, food preparation, food science, etc. It can solve the problems of reducing the uniformity of quality and the final refraction sugar content of aloe mesophyll, so as to reduce production costs, high-quality taste and smoothness, The effect of simple canning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

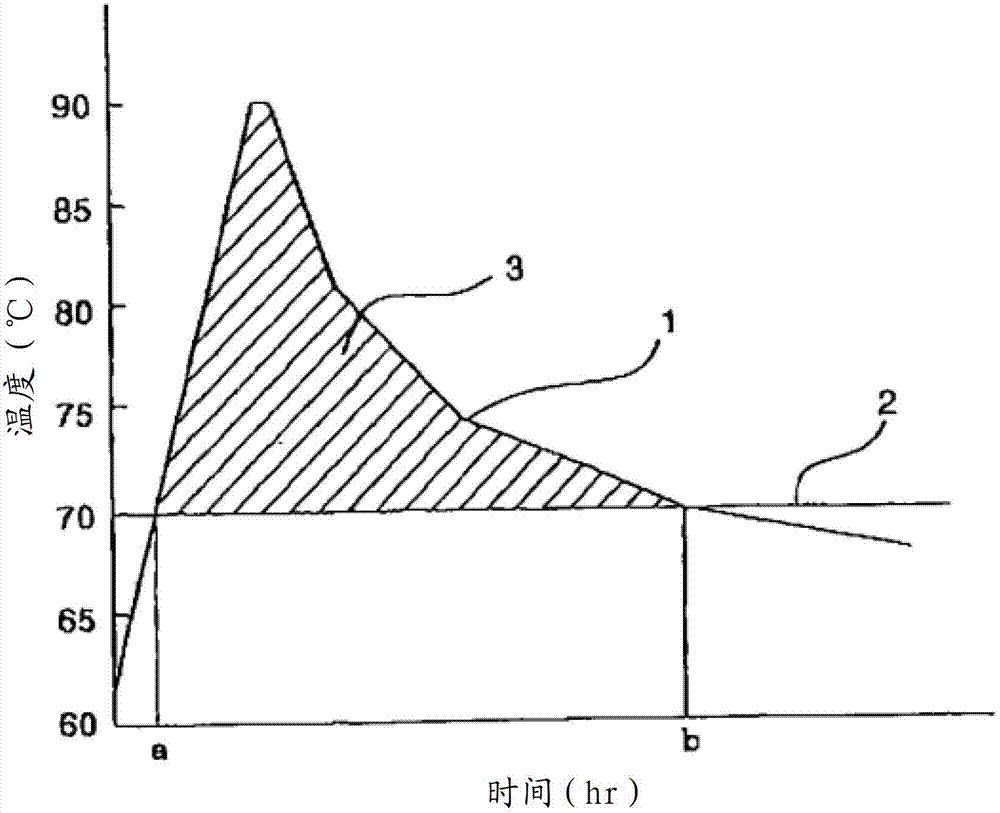

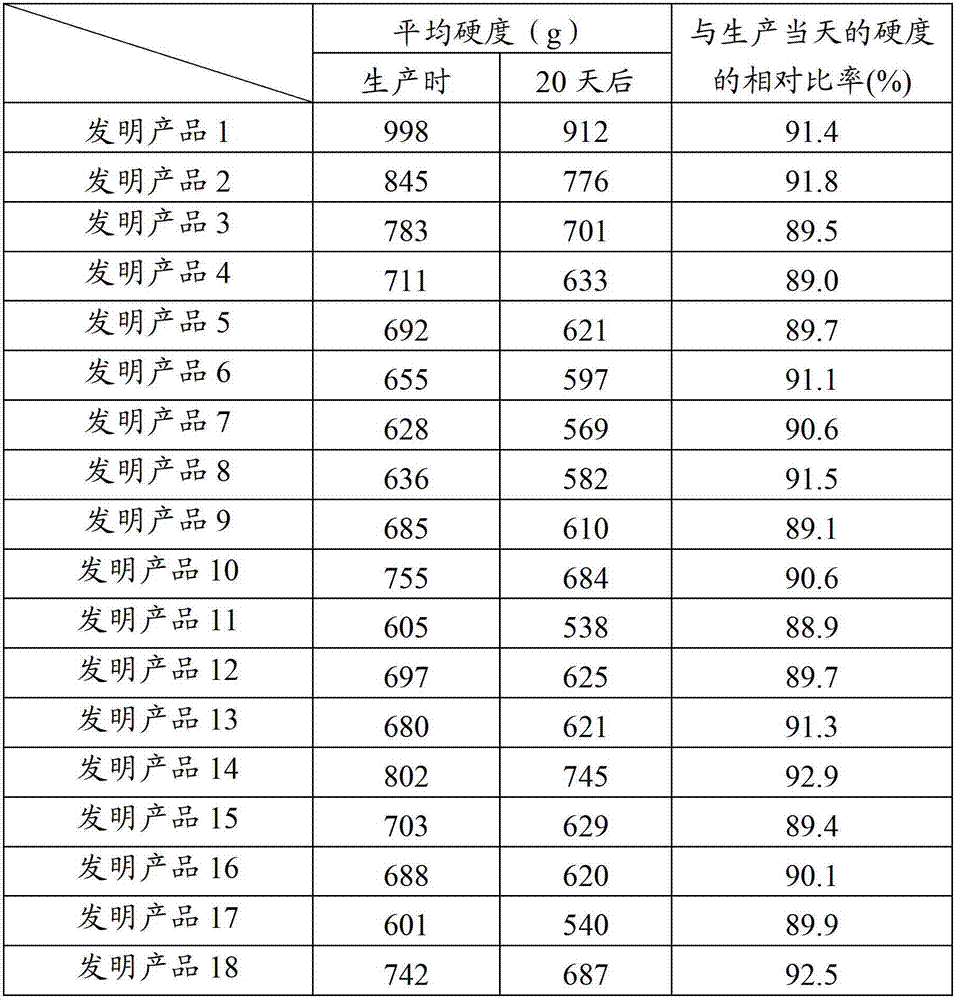

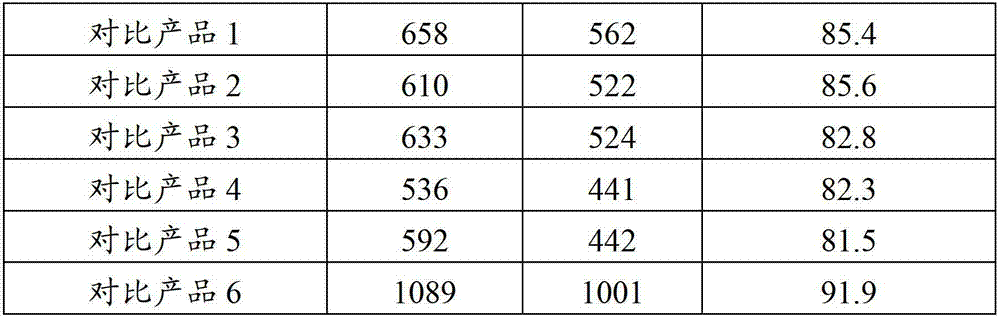

[0069] Example 1 (10mm aloe mesophyll of 230kg, heat sterilization at 90°C for 3 minutes, cooled to 73°C, then put into heat-resistant bag / steel drum-shaped jar)

[0070] The aloe is peeled off, then cut into small pieces with a size of about 10mm, and then cleaned and screened. Add the obtained aloe mesophyll (180kg) and 50kg syrup (the weight ratio of sugar, citric acid and water is 80:1:30) into a jacketed heating and stirring tank to prepare the aloe mesophyll preserved in the syrup. Under the condition of 40rpm at stirring speed, the aloe mesophyll preserved by syrup was heated at 90°C for 3 minutes, then water was passed into jacket and cooled to 73°C.

[0071] Next, when the temperature reached 73°C, all the ingredients of the aloe mesophyll preserved by the above syrup were loaded into the container from the heating and stirring tank through the pump under aseptic conditions. The container used has an inner bag and an outer package, and the inner bag is placed in the ...

Embodiment 2

[0077] Example 2 (230kg of 10mm aloe vera mesophyll, sterilized by heat at 90°C for 10 minutes, cooled to 73°C, and then put into a heat-resistant bag / steel drum-shaped tank)

[0078] The aloe is peeled off, then cut into small pieces with a size of about 10mm, and then cleaned and screened. Add the obtained aloe mesophyll (180kg) and 50kg syrup (the weight ratio of sugar, citric acid and water is 80:1:30) into a jacketed heating and stirring tank to prepare the aloe mesophyll preserved in the syrup. The aloe mesophyll preserved in syrup was heated at 90° C. for 10 minutes at a stirring speed of 40 rpm, and then water was passed into the jacket and cooled to 73° C.

[0079] Next, when the temperature reached 73°C, the same procedure as in Example 1 was performed. As a result, when the room temperature was 38° C., the temperature of the aloe mesophyll preserved in the syrup in the container reached 70° C. after about 3 hours. Be that the area of the part surrounded by the t...

Embodiment 3

[0084] Example 3 (230kg of 10mm aloe vera mesophyll, sterilized by heat at 95°C for 10 minutes, cooled to 73°C, and then put into a heat-resistant bag / steel drum-shaped tank)

[0085] The aloe is peeled off, then cut into small pieces with a size of about 10mm, and then cleaned and screened. Add the obtained aloe mesophyll (180kg) and 50kg syrup (the weight ratio of sugar, citric acid and water is 80:1:30) into a jacketed heating and stirring tank to prepare the aloe mesophyll preserved in the syrup. The aloe mesophyll preserved in the syrup was heated at 95° C. for 10 minutes at a stirring speed of 40 rpm, and then water was passed into the jacket and cooled to 73° C.

[0086] Next, when the temperature reached 73°C, the same procedure as in Example 1 was performed. As a result, when the room temperature was 38° C., the temperature of the aloe mesophyll preserved in the syrup in the container reached 70° C. after about 3 hours. Be that the area of the part surrounded by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com