Preparation method of 2, 5-bis (benzoxazole-2-) furan

A technology of benzoxazole and furan, applied in the field of preparation of 2,5-bisfuran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The invention provides a preparation method of 2,5-bis(benzoxazole-2-)furan, which is characterized in that the method comprises: making furan-2,5-dicarboxylic acid and o-aminophenol in a solvent A condensation reaction occurs under the action of a catalyst, the solvent is: 1-methylnaphthalene, and the catalyst is boric acid;

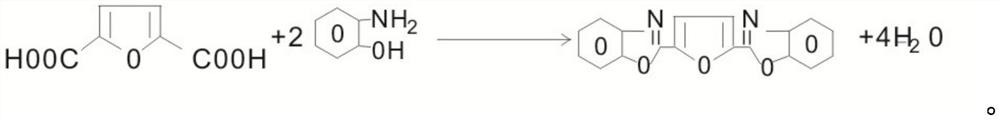

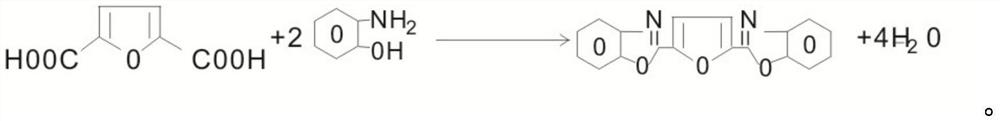

[0010] The chemical reaction principle is:

[0011]

[0012] Wherein, in the present invention, the amount of furan-2,5-dicarboxylic acid and o-aminophenol is not particularly limited, as long as condensation reaction can occur, but from the perspective of more efficient reaction, the furan-2,5 - The molar ratio of dicarboxylic acid and said o-aminophenol is preferably 1:(2-2.2).

[0013] The present invention also has no particular limitation on the amount of the solvent and the catalyst. The amount of the solvent may be 9-10 times the mass of the furan-2,5-dicarboxylic acid, and the amount of the catalyst may be the 0.15-0.2 times the mass...

Embodiment 1

[0024] Add 1200L of 1-methylnaphthalene, 124.8kg of furan-2,5-dicarboxylic acid, and 174.4kg of o-aminophenol into the cleaned 2000L stainless steel reactor (with nitrogen pipe, condenser, thermometer, water separator, etc.) , Boric acid 20kg. At this time, the molar ratio of furan-2,5-dicarboxylic acid and o-aminophenol was 1:2, the amount of 1-methylnaphthalene was 9.6 times the mass of furan-2,5-dicarboxylic acid, and the amount of boric acid was It is 0.16 times the mass of furan-2,5-dicarboxylic acid.

[0025] After feeding, nitrogen was introduced at a constant rate, kept at 3 cubic meters per hour, started stirring, slowly heated to 140 °C with heat-conducting oil, kept at 140 °C for 3 hours, then heated to 200 °C, and kept at 200 °C for 5 hours for a total of 5 hours. About 57.6 kg of water distilled during the reaction was obtained.

[0026] After the reaction is completed, the 1-methylnaphthalene solvent is distilled out under the negative pressure of the water flu...

Embodiment 2

[0032] Add 1125L of 1-methylnaphthalene, 124.8kg of furan-2,5-dicarboxylic acid, 176kg of o-aminophenol, Boric acid 25kg. At this time, the molar ratio of furan-2,5-dicarboxylic acid and o-aminophenol was 1:2.02, the amount of 1-methylnaphthalene was 9 times the mass of furan-2,5-dicarboxylic acid, and the amount of boric acid was It is 0.2 times the mass of furan-2,5-dicarboxylic acid.

[0033] After feeding, nitrogen was introduced at a constant rate, kept at 2 cubic meters per hour, started stirring, slowly heated to 150°C with heat-conducting oil, kept at 150°C for 2 hours, and then heated to 210°C, kept at 210°C for 4 hours, for a total of 4 hours. About 57.6 kg of water distilled during the reaction was obtained.

[0034] After the reaction is completed, the 1-methylnaphthalene solvent is distilled out under the negative pressure of the water flushing pump until there is no distillation, and the steamed 1-methylnaphthalene is reused for the next batch of reactions. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com