Device and method for perforating films

A kind of equipment and film technology, which is applied in the field of film punching equipment, can solve the problems of expensive and worn parts of cutting components, and achieve the effect of minimum operating cost and simple adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

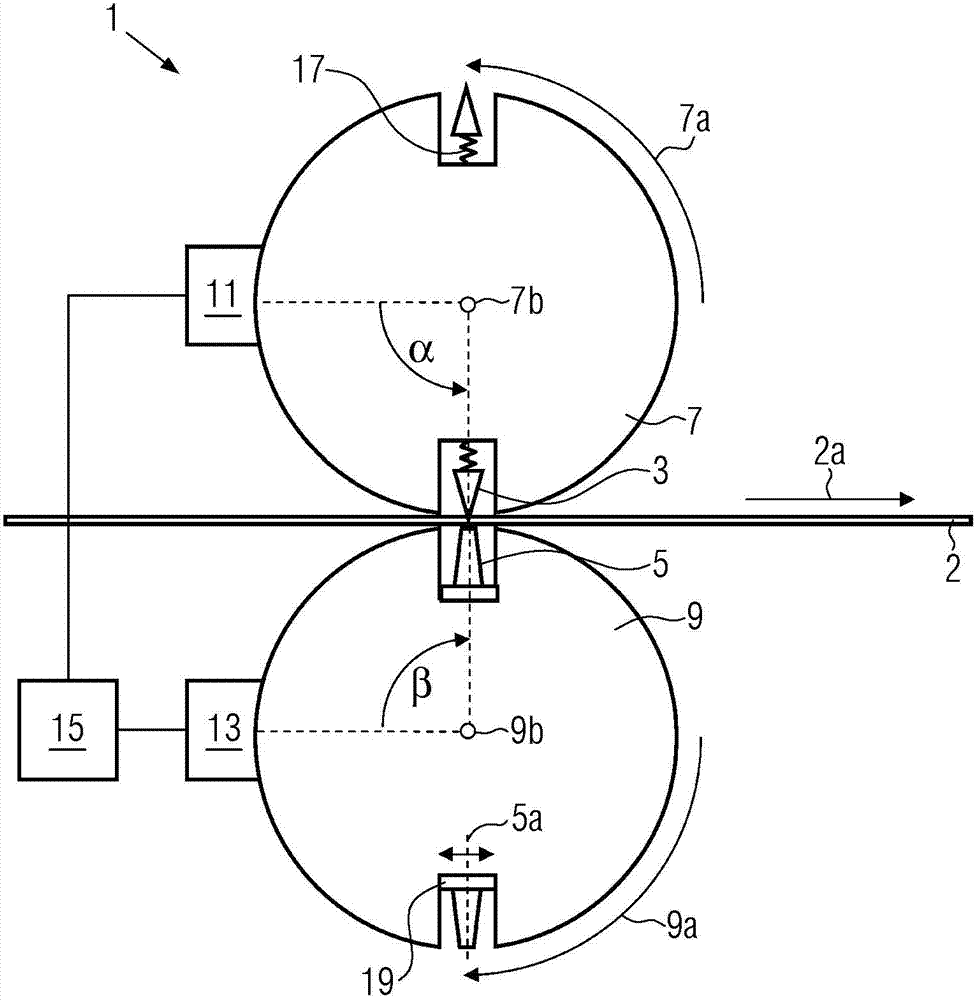

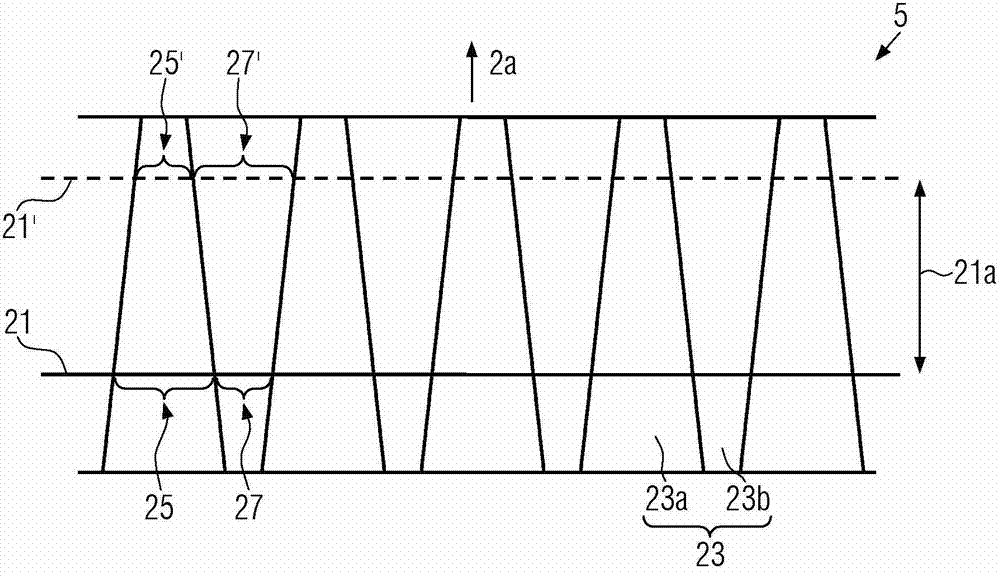

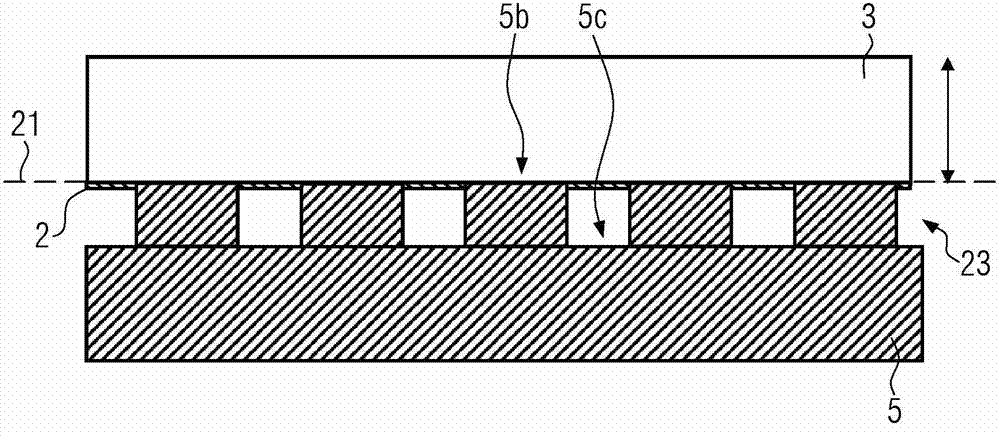

[0029] Such as figure 1It can be seen that the first embodiment 1 of the device according to the invention for the perforation of the film 2 comprises at least one cutting element 3 and at least one counter-cutting element 5 , through which the contact of the cutting element and the counter-cutting element with the film 2 results in an Make punch holes in. Preferably, the cutting element 3 is arranged on a cutting roller 7 with a direction of rotation 7 a or on another rotatable holding device, and the counter cutting element 5 is arranged on a corresponding cutting roller 9 with a direction of rotation 9 a or on another rotatable holding device device, wherein the axes of rotation 7b and 9b are oriented parallel to each other. In addition if figure 1 As indicated, on the cutting roller 7 , in particular at least two cutting elements 3 are distributed uniformly around the periphery, and on the counter-cutting roller 9 there is a corresponding number of counter-cutting elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com