Method for preparing ordered mesoporous metal oxide material with adjustable particle size

A technology of particle size and oxide, applied in the direction of chemical instruments and methods, iron oxide, carbon compounds, etc., can solve the problems of limited effectiveness and achieve the effect of improving application performance, simple operation, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The following is a further detailed description of the present invention based on the existing preparation method and our invention:

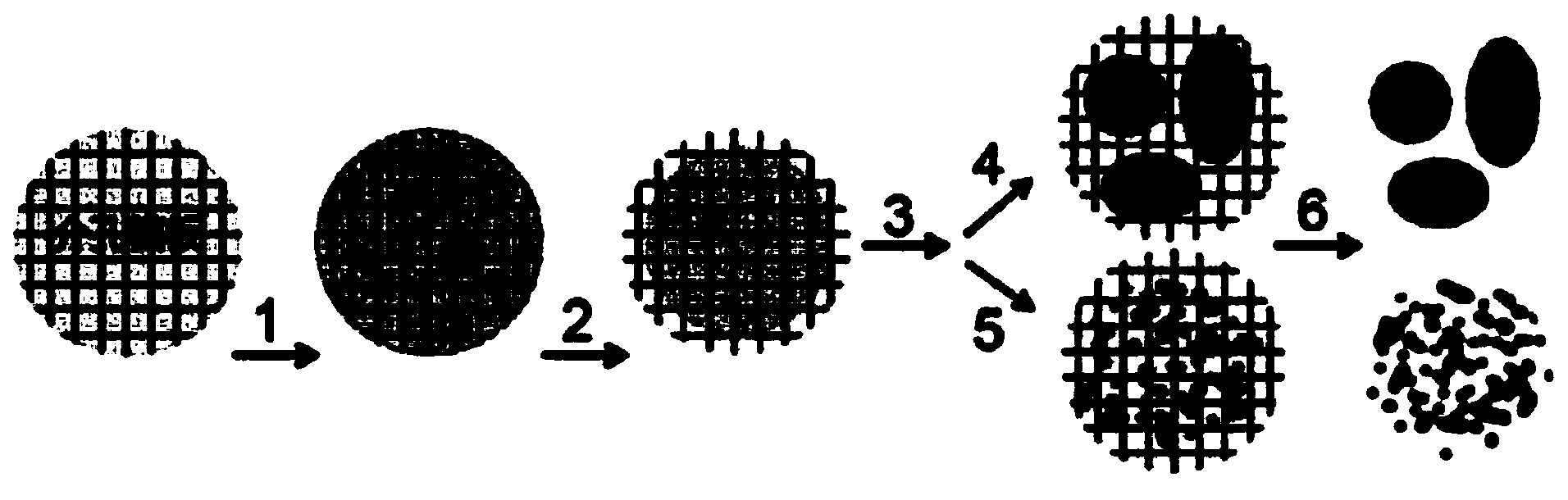

[0022] A preparation method of ordered mesoporous metal oxide material with adjustable particle size, which comprises the following steps:

[0023] 1) Preparation of ordered mesoporous silica template material: mix and stir the surfactant, water, butanol and hydrochloric acid until the surfactant is dissolved, then add ethyl orthosilicate and stir at 25-35°C for 12-24 hours , Then transfer the mixture to a hydrothermal reactor for 1-4 days at 100-130°C. After cooling naturally, it will be filtered, washed, dried and calcined in an air atmosphere at 350-600°C for 2-5 hours to remove the surfactant. Obtain a white powder sample for use;

[0024] The surfactant is a triblock copolymer P123(OH(CH 2 CH 2 O) 20 (CH 2 CH(CH 3 )O) 70 (CH 2 CH 2 O) 20 H,MW=5800);

[0025] The molar ratio of the ethyl orthosilicate, P123, hydrochloric acid, water, and bu...

Embodiment 1

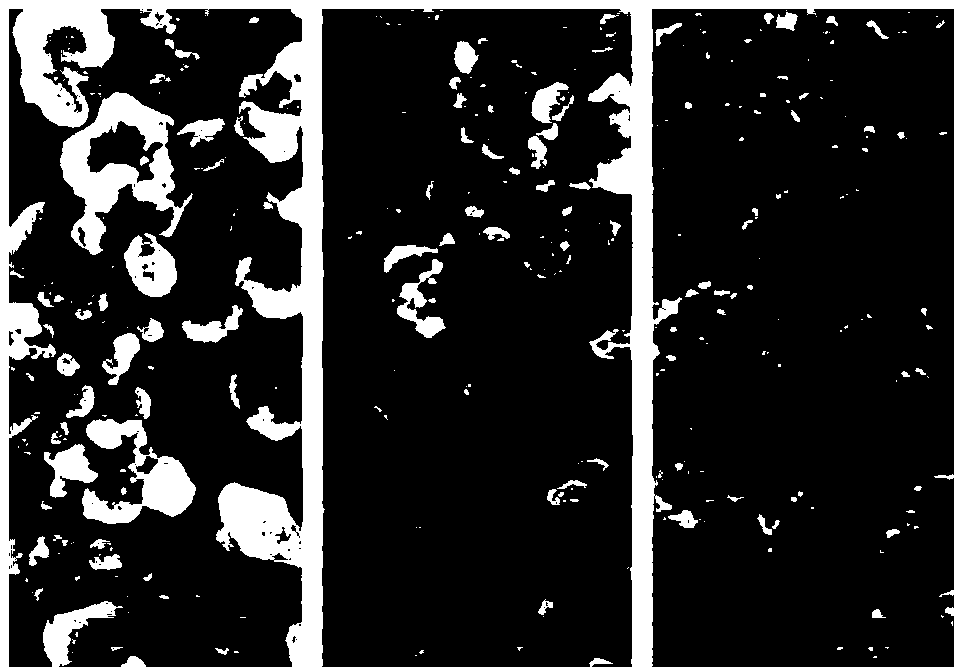

[0031] Example 1, by controlling the volume of the calcining vessel (the vessel volume is from 1.5ml to 20ml to 700ml), the prepared ordered mesoporous Fe 2 O 3 The particle size of the material.

[0032] Mix 6g of surfactant P123, 217g of water, 6g of butanol and 11.8g of hydrochloric acid (concentration of 35%) until the surfactant is dissolved, then add 12.9g of ethyl orthosilicate and stir at 35°C for 12 hours. The mixture was transferred to a hydrothermal reactor and reacted at 120°C for 1 day. After natural cooling, it was filtered, washed, dried and calcined in an air atmosphere at 400°C for 3 hours to remove the surfactant to obtain a white powder of ordered mesoporous silica for use. ;

[0033] Using 3g of the above ordered mesoporous silica as a hard template, disperse it in 60g of ethanol, add 9g of ferric nitrate, stir and impregnate at room temperature, so that the iron precursor is immersed in the silica mesoporous channels, and then the ethanol solvent is evaporated....

Embodiment 2

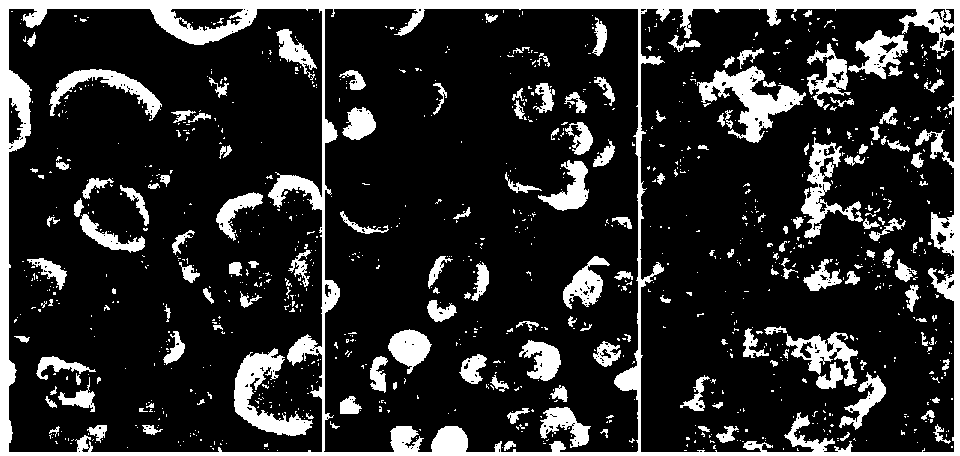

[0034] Example 2, by controlling the size of the opening of the calcining vessel (from completely closed, to 50% open to completely open), the prepared ordered mesoporous In 2 O 3 The particle size of the material.

[0035] Mix 6g of surfactant P123, 217g of water, 6g of butanol and 11.8g of hydrochloric acid (concentration of 35%) until the surfactant is dissolved, then add 12.9g of ethyl orthosilicate and stir at 35°C for 12 hours. The mixture was transferred to a hydrothermal reactor and reacted at 120°C for 1 day. After natural cooling, it was filtered, washed, dried and calcined in an air atmosphere at 400°C for 3 hours to remove the surfactant to obtain a white powder of ordered mesoporous silica for use. ;

[0036] Using 3g of the above ordered mesoporous silica as a hard template, disperse it in 60g of ethanol, add 9g of indium nitrate, and stir and impregnate at room temperature so that the indium precursor is immersed in the mesoporous channels of the silica, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com